filmov

tv

Lathe Talks - Three Years With The Warco WM 180 Lathe

Показать описание

Having now owned the Warco WM 180 for over 3 years, I thought it would be useful to talk about what I've learned. Also, what I think are the most important things to consider when using one of these mini lathes.

Lathe Talks - Three Years With The Warco WM 180 Lathe

Warco WM180 REVIEW 3 Months ON

Mini Lathe Basics Introduction

vmc machine ATC functions working | Automatic tool change #vmc #ATC #machine

Incredible Milling on a Lathe

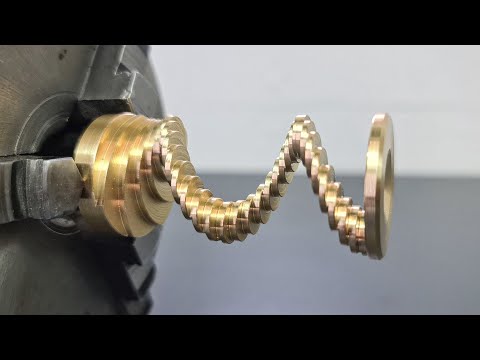

Turning Flat Surfaces with Polygon Turning 🤯

Interesting Option for 3-Axis CNC Mills

History of Lathes | The Henry Ford's Innovation Nation

Making a Crazy Part on the Lathe - Manual Machining

Nexturn SA-32XIII 3-Channel & 3 Y-Axes Swiss Lathe at IMTS 2022

Can you explain how This work? Boring drilling work

Grizzly Gunsmithing Lathes with Shiraz Balolia

Clausing 1300/1301 Metal Lathe 13' x 36' 3 PH 3 Jaw Chuck

Fitting a DRO on Warco WM180 MINI Lathe

New video Compare: 3 jigs and two sharpening stations #woodturning #woodworking @TormekSharpening

COMPARING SOUTH BEND 9' LATHE MODELS #785 tubalcain type study

We’ve been on lockdown for 13 days. Our teacher wants to eat us out

Worst ways people have died😰 #shorts

INTERNAL TURNING 👀🪚⛓️👁️ AND BORING 🛠️💨🔨 #machine #technology #turning

CNC/PLC MACHINE PRACTICAL FANUC #cnc #cnclathe #cncmachine #cncoperating #cncprogramming#vmc#cncbook

Bloody apprentices! #machinist #joke #lathe

Wood turning into bowl | Woodturning into bowl | WOOD TURNING INTO BOWL

Turn-Mill Machining 🔥🔥

CNC Gear Hobbing Process

Комментарии

0:21:56

0:21:56

0:14:04

0:14:04

0:07:00

0:07:00

0:00:14

0:00:14

0:00:07

0:00:07

0:00:08

0:00:08

0:00:09

0:00:09

0:03:36

0:03:36

0:04:15

0:04:15

0:01:33

0:01:33

0:00:16

0:00:16

0:03:29

0:03:29

0:03:07

0:03:07

0:15:18

0:15:18

0:00:59

0:00:59

0:16:36

0:16:36

0:01:00

0:01:00

0:00:20

0:00:20

0:00:11

0:00:11

0:00:16

0:00:16

0:00:11

0:00:11

0:00:55

0:00:55

0:00:08

0:00:08

0:00:06

0:00:06