filmov

tv

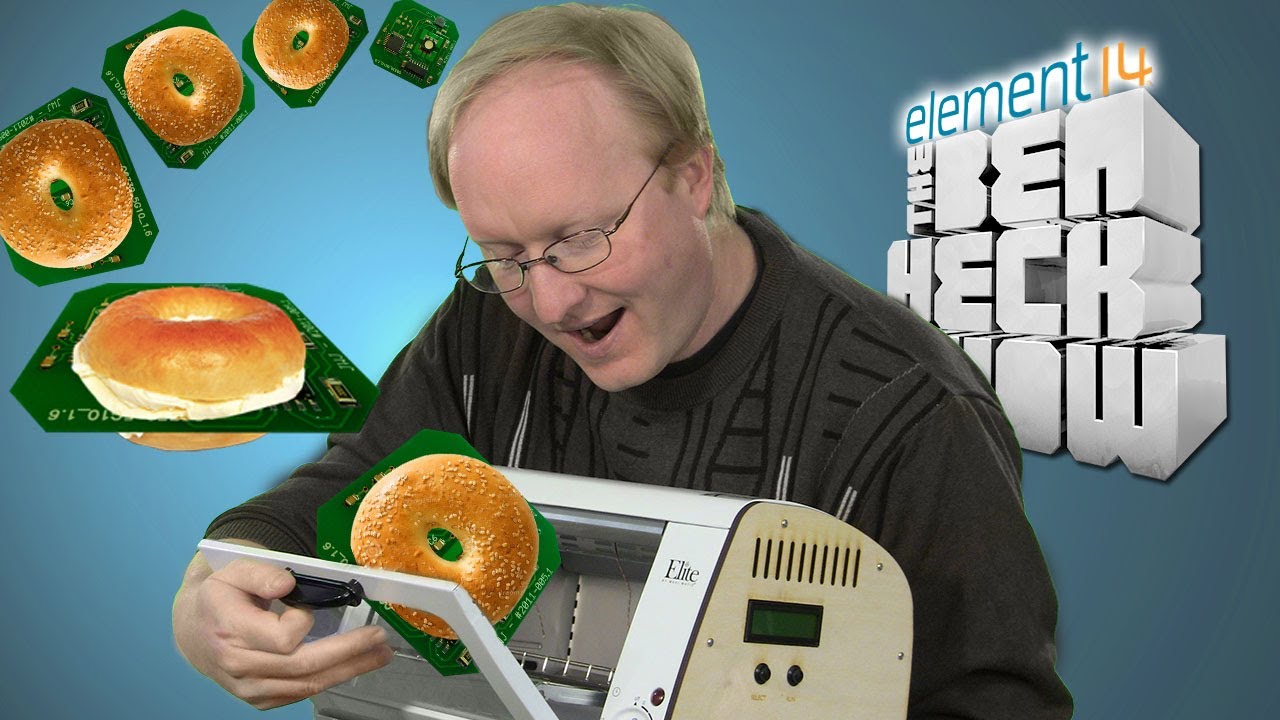

Ben Heck's Home-Brew Solder Reflow Oven 2.0

Показать описание

Ben's fed-up with the difficulty of soldering surface-mount components by hand and builds a new reflow oven to keep in his shop. He transforms an inexpensive toaster over into a vital tool for electronics engineers and tinkerers. In this updated oven, he uses two thermal couples to ensure even heat distribution and effective reflow.

Stay tuned each Sunday for all new episodes!

Connect with The Ben Heck Show for more projects and tips

Stay tuned each Sunday for all new episodes!

Connect with The Ben Heck Show for more projects and tips

Ben Heck's Home-Brew Solder Reflow Oven 2.0

Solder Over: Transform Your Toaster Oven In To A Solder Reflow Oven

Surface Mount Soldering Tips and Tricks

Ben's Wearable Solder Gauntlet Part 2

The Great Glue Gun Part 1

Ben Kickstarts His OUYA Portable Build Part 2

The Ben Heck Show vs. Hak5 PC Case Mod Battle!!

Second Attempt: SMD Reflow Soldering

Ben's Steampunk Persistence of Vision Display

Ben Heck's TI Launchpad Plant Booster

Ben Heck's EMFCamp Extreme Camping Chair

Making a Reflow Oven (v. 1.0)!

Building a DIY Reflow Oven

What Does Ben Heck Hack? #Shorts

Ben Heck's Raspberry S-pi Cam Part 2

946A+ Solder Reflow Hot Plate Workshop Video

Ultra Rare Vectrex Repair

DIY Arduino Controlled Toaster Reflow Oven Build

Ben Heck's Laser Printer Salvage

Let's Go Fly a Quadcopter - Part 2

Ben Heck's Magic Smoke Preventor

My version of a DIY reflow oven Part 4

Homemade Reflow System - XBOX 360 / Ps3

Soldering high-density SMT LED array using DIY reflow oven

Комментарии

0:15:01

0:15:01

0:17:51

0:17:51

0:16:10

0:16:10

0:22:29

0:22:29

0:15:47

0:15:47

0:17:52

0:17:52

0:18:02

0:18:02

0:16:01

0:16:01

0:15:12

0:15:12

0:21:15

0:21:15

0:25:30

0:25:30

0:11:36

0:11:36

0:05:27

0:05:27

0:00:45

0:00:45

0:16:20

0:16:20

0:05:33

0:05:33

0:14:57

0:14:57

0:13:51

0:13:51

0:22:08

0:22:08

0:16:55

0:16:55

0:22:43

0:22:43

0:15:37

0:15:37

0:06:57

0:06:57

0:06:32

0:06:32