filmov

tv

Structural Shapes Ranked and Reviewed - Which one Wins?

Показать описание

There are many structural shapes and for the most part, they all have at least one feature that is more advantages compared to the other shapes. Deciding on which one is the best structural shape is not straight forward (and probably not possible) since being able to resist high loads is only the beginning of the analysis. In this video, we (attempt to) analyze and rank the most common structural shapes. Our analysis takes a fixed area to compare various shapes in terms of bending, buckling, torsion, symmetry, and workability.

00:00 - Intro

00:58 - Analysis Criteria

04:01 - I-Beam (Wide Flange)

05:34 - Rectangular

07:47 - Circular

09:57 - Channel

11:17 - Tee

12:04 - Angle

12:59 - Analysis Results and Discussion

14:13 - Sponsorship!

This video was sponsored by Brilliant!

Structural Shapes Ranked and Reviewed - Which one Wins?

What are the Different Structural Steel Shapes?

Engineer explains: Are triangles REALLY the strongest shape?

The Critical Weakness of the I-Beam

Why Are Steel Beams I-Shaped?

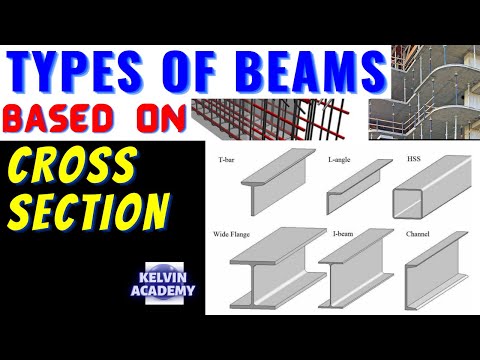

TYPES OF BEAMS BASED ON THE SHAPE OF THE CROSS SECTIONS

#011 Exploring Hollow Structural Shapes

Why Rectangular Beams are preferred than Circular Beams

ADVANCED STRUCTURAL SHAPES

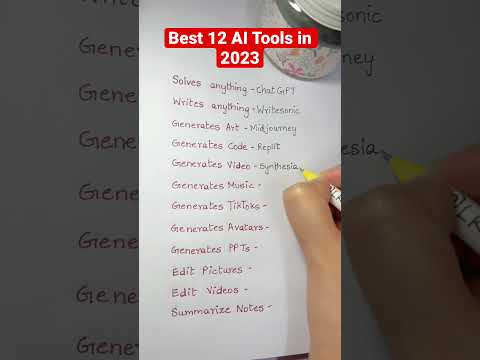

Best 12 AI Tools in 2023

What Are the Types of Rolled Structural Steel Shapes? | Structural Engineering | PE Civil

Discover the Versatility and Strength of MS Angle: The Ideal Building Material for Your Projects.

5 Top equations | Steel Truss Design every Structural Engineer should know

The Strength of a Curve | Super Structures

Types of Structural Stainless Steel Shapes

Carbon steel H-beam

Hollow tube stock a500 grade b hollow section with various dimensions in China

different types of steel structures #ARASHA

Wide Flange Shapes (W-Shapes), Table of Section Properties for WF Profiles

Difference between H & I-beam || Usage of Beams in fabrication industry

STRUCTURAL STEEL I- BEAM ( SPRAY PAINTING )

Stainless steel square tube connectors! High

Bro Skipped Muscles For Strength... 🤦♂️

The Manufacturing of Structural Steel Shapes

Комментарии

0:15:34

0:15:34

0:18:35

0:18:35

0:02:49

0:02:49

0:06:14

0:06:14

0:00:30

0:00:30

0:12:14

0:12:14

0:10:58

0:10:58

0:05:35

0:05:35

0:12:14

0:12:14

0:00:36

0:00:36

0:03:48

0:03:48

0:00:58

0:00:58

0:03:09

0:03:09

0:01:24

0:01:24

0:01:18

0:01:18

0:00:12

0:00:12

0:00:17

0:00:17

0:00:16

0:00:16

0:08:02

0:08:02

0:05:14

0:05:14

0:00:10

0:00:10

0:00:15

0:00:15

0:00:33

0:00:33

0:24:58

0:24:58