filmov

tv

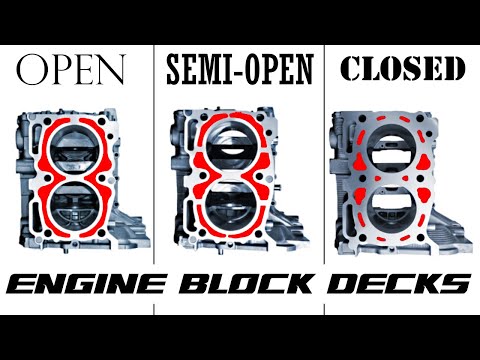

ENGINE BLOCK DECKS: Open vs Closed vs Semi Open

Показать описание

What is up engine heads, in today's episode we're talking about the differences between open deck engines, closed deck engines and semi-open (semi-closed) deck engines. After watching this video you'll be able to identify the different engine block deck designs but you'll also know how they differ from each other in terms of strength, cooling, their performance potential and more.

The key difference between open, closed and semi closed engine block decks is the structural reinforcement in the coolant passage area at the top of the cylinders, that is the engine deck area. Open deck engines will have the entire coolant passage are around the top of the cylinders free and open. Semi-closed decks will also be mostly open, but will have structural reinforcements in the form of little "stems" or "pillars" between the cylinders and engine block walls. The name of the closed deck engine is somewhat misleading because the area around the top of the cylinders isn't really fully closed of course, but there are opening left for the coolant to pass through. Subaru is an interesting brand here because they made virtually the same blocks in all three versions of the deck design.

Now if you look up the differences between open deck vs closed deck vs semi closed deck engine blocks online you will likely run into an over-generalization of how closed deck blocks are the strongest because they have the most structural reinforcement and how open deck engines are the weakest because they lack structural reinforcements, but how they have the best cooling because of the largest cooling passages. You'll also likely read how if you're interested in a performance forced induction build you should stick to a closed deck block or reinforce an open or semi open deck block. This information does make sense but it's really outdated and comes from the early days of turboing engines. Closed deck engines are stronger than open and semi open deck ones, but it's not that simple and open decks are not as weak as the internet might try to convince you.

Here's an example. The BMW N54 is BMW's first turbo engine in a pretty long time. Some call the N54 the modern day RB26 or the modern day 2JZ. Just like the 2JZ, the N54 is an inline six cylinder, 3.0 liter twin turbo engine, but unlike the 2jz, which is a cast iron closed deck engine, the N54 has an open deck aluminum block, so it stands at the opposite end of the perceived block strength scale. That means it should be weak right? It should fall apart when boost is increased? But today capable tuners and enthusiasts take the bone stock N54 block to beyond 700 whp. And the N54 is just one example there are plenty more modern open deck designs (k20c, ford ecoboost, volvo t5 and many others) where you can increase the boost without the blocks or the cylinder sleeves complaining at all.

So how come, why are open deck designs so popular today, and why aren't they falling apart under increased boost. They're popular because they're cheaper and easier to manufacture compared to closed deck designs. Open deck engines can be made using high pressure die casting (hpdc) which is cheaper and simpler compared to methods needed for closed deck engine blocks. But the other side of the coin is that casting technology has come a long way, and is far better and more accurate then decades ago, which enables manufacturers to make much stronger and better open deck blocks. On top of that manufactures have access to sophisticated CAD and simulation software that enables a better and more complex block and deck design.

But there's something else that plays an important part as well, and that is tuning technology. ECUs and sensors are much better, much more sensitive and capable than they were decades ago. They are able to sense knock better and react faster to prevent it. The open deck design of the Honda B16 was blamed for the cylinders cracking under boost of these engines in the late 90s. Today we know that the B16 block is good and can sustain well over 400hp on the stock block. What happened in the 90s is that knock happened but the sensors and ECUs did not sense it and react fast enough to preven it. In most cases knock cracks cylinder sleeves, not boost. Just look at the Honda K20 today, capable tuners are taking it well beyond twice it's power level on the stock block. Something that was impossible a few decades ago without significantly shortening the lifespan of the engine. So the key takeaway is that the open deck and semi open deck engines aren't weaker, they actually have a smaller margin of error for knock, but good tuning and modern electrinics are capable of keeping the engine safe, even within a smaller margin for error.

A very special thank you to my Patron:

Daniel

driving 4 answers is part of the Amazon Associates program.

#d4a #enginebootcamp #engine

The key difference between open, closed and semi closed engine block decks is the structural reinforcement in the coolant passage area at the top of the cylinders, that is the engine deck area. Open deck engines will have the entire coolant passage are around the top of the cylinders free and open. Semi-closed decks will also be mostly open, but will have structural reinforcements in the form of little "stems" or "pillars" between the cylinders and engine block walls. The name of the closed deck engine is somewhat misleading because the area around the top of the cylinders isn't really fully closed of course, but there are opening left for the coolant to pass through. Subaru is an interesting brand here because they made virtually the same blocks in all three versions of the deck design.

Now if you look up the differences between open deck vs closed deck vs semi closed deck engine blocks online you will likely run into an over-generalization of how closed deck blocks are the strongest because they have the most structural reinforcement and how open deck engines are the weakest because they lack structural reinforcements, but how they have the best cooling because of the largest cooling passages. You'll also likely read how if you're interested in a performance forced induction build you should stick to a closed deck block or reinforce an open or semi open deck block. This information does make sense but it's really outdated and comes from the early days of turboing engines. Closed deck engines are stronger than open and semi open deck ones, but it's not that simple and open decks are not as weak as the internet might try to convince you.

Here's an example. The BMW N54 is BMW's first turbo engine in a pretty long time. Some call the N54 the modern day RB26 or the modern day 2JZ. Just like the 2JZ, the N54 is an inline six cylinder, 3.0 liter twin turbo engine, but unlike the 2jz, which is a cast iron closed deck engine, the N54 has an open deck aluminum block, so it stands at the opposite end of the perceived block strength scale. That means it should be weak right? It should fall apart when boost is increased? But today capable tuners and enthusiasts take the bone stock N54 block to beyond 700 whp. And the N54 is just one example there are plenty more modern open deck designs (k20c, ford ecoboost, volvo t5 and many others) where you can increase the boost without the blocks or the cylinder sleeves complaining at all.

So how come, why are open deck designs so popular today, and why aren't they falling apart under increased boost. They're popular because they're cheaper and easier to manufacture compared to closed deck designs. Open deck engines can be made using high pressure die casting (hpdc) which is cheaper and simpler compared to methods needed for closed deck engine blocks. But the other side of the coin is that casting technology has come a long way, and is far better and more accurate then decades ago, which enables manufacturers to make much stronger and better open deck blocks. On top of that manufactures have access to sophisticated CAD and simulation software that enables a better and more complex block and deck design.

But there's something else that plays an important part as well, and that is tuning technology. ECUs and sensors are much better, much more sensitive and capable than they were decades ago. They are able to sense knock better and react faster to prevent it. The open deck design of the Honda B16 was blamed for the cylinders cracking under boost of these engines in the late 90s. Today we know that the B16 block is good and can sustain well over 400hp on the stock block. What happened in the 90s is that knock happened but the sensors and ECUs did not sense it and react fast enough to preven it. In most cases knock cracks cylinder sleeves, not boost. Just look at the Honda K20 today, capable tuners are taking it well beyond twice it's power level on the stock block. Something that was impossible a few decades ago without significantly shortening the lifespan of the engine. So the key takeaway is that the open deck and semi open deck engines aren't weaker, they actually have a smaller margin of error for knock, but good tuning and modern electrinics are capable of keeping the engine safe, even within a smaller margin for error.

A very special thank you to my Patron:

Daniel

driving 4 answers is part of the Amazon Associates program.

#d4a #enginebootcamp #engine

Комментарии

0:11:47

0:11:47

0:08:49

0:08:49

0:04:05

0:04:05

0:00:43

0:00:43

0:05:50

0:05:50

0:02:42

0:02:42

0:00:52

0:00:52

0:02:42

0:02:42

5:22:23

5:22:23

0:08:27

0:08:27

0:03:08

0:03:08

0:07:27

0:07:27

0:00:47

0:00:47

0:02:27

0:02:27

0:06:12

0:06:12

0:01:06

0:01:06

0:03:58

0:03:58

0:13:08

0:13:08

0:00:35

0:00:35

0:03:37

0:03:37

0:47:24

0:47:24

0:13:51

0:13:51

0:00:23

0:00:23

0:07:18

0:07:18