filmov

tv

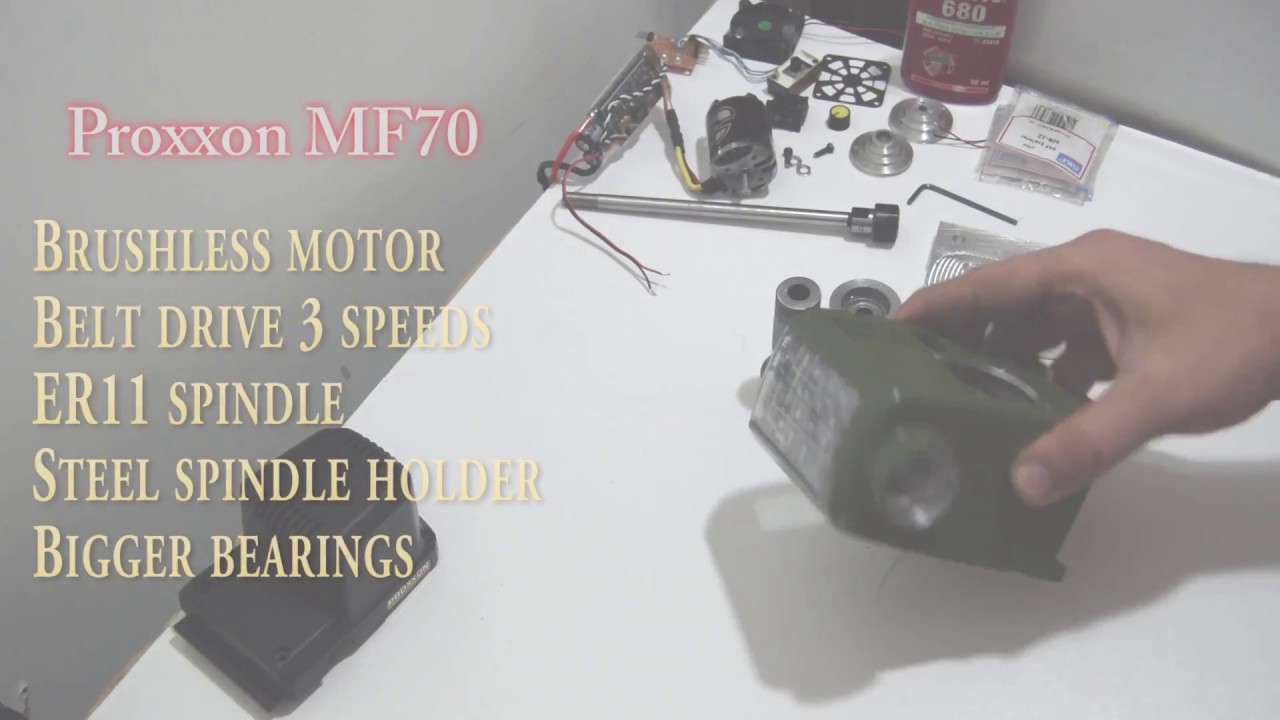

Proxxon MF70 brushless belt er11 spindle upgrade

Показать описание

Upgrading a CNC MF70 mini mill spindle to ER11 chuck, steel spindle holder, brushless motor, 3 speeds belt driven for ranges between 0-7k high torque to 0-26k high rpm.

The brushless is a 3548 1100kv. The electronics is the esc for the brushless and a esc tester to control the speed, nothing custom made.

6 years so far going strong, bearings or the motor never failed. Machining aluminium is extremly easy with this setup and even steel with slow speeds.

The brushless is a 3548 1100kv. The electronics is the esc for the brushless and a esc tester to control the speed, nothing custom made.

6 years so far going strong, bearings or the motor never failed. Machining aluminium is extremly easy with this setup and even steel with slow speeds.

Proxxon MF70 brushless belt er11 spindle upgrade

Proxxon MF70 modifications, ER11 collet, brushless engine, KT230 cross table. How it's made.

Proxxon MF70 - Brushless motor A2212 + ER11 spindle upgrade (cheap 25-30 usd) + test milling @ 11:13

Precision spindle for Proxxon MF70

Proxxon mf70 cnc, quick video

Hexagon #2 - Rotary milling - part 2/2

Proxxon MF70 modification. High torque transmission (Part 2)

Proxxon MF70 modification. High torque transmission (Part 3)

Proxxon MF70 modification. High torque transmission (Part 1)

Unboxing proxxon MF70

video proxxon MF70 venda no ML

PROXXON MF70 CNC

MINIM-e PROXXON MF70 CNC upgrade

New spindle. World smallest surface grinder. Part 3.

Proxxon MF70 CNC - First Mild Steel Milling Test

Home made Arduino uno cnc Brushless motor spindle

How to Make DIY Brushless Spindle For DIY CNC

Proxxon mf 70 CNC Gravure photo sur bois avec laser 1W et LaserGRBL

DIY brushless spindle milling machine in action

Another Proxxon MF70 CNC Conversion - Part 1 - Z axis

My Humble Hand-mold (Typecasting + Proxxon CNC)

Experiment with Proxxon for Denon DR-M34HR reel motor idler drive

Musical: Test Lead Rack

Can The MyPlasm CNC Run a Brushless Spindle and a VFD?? DIY CNC Plasma Table / CNC Router Table!!

Комментарии

0:02:55

0:02:55

0:20:05

0:20:05

0:13:18

0:13:18

0:15:22

0:15:22

0:00:40

0:00:40

0:30:33

0:30:33

0:25:58

0:25:58

0:29:06

0:29:06

0:19:36

0:19:36

0:02:00

0:02:00

0:00:53

0:00:53

0:00:36

0:00:36

0:04:26

0:04:26

0:21:56

0:21:56

0:01:44

0:01:44

0:00:32

0:00:32

0:04:55

0:04:55

0:02:37

0:02:37

0:00:44

0:00:44

0:14:08

0:14:08

0:05:39

0:05:39

0:00:40

0:00:40

0:04:45

0:04:45

0:09:25

0:09:25