filmov

tv

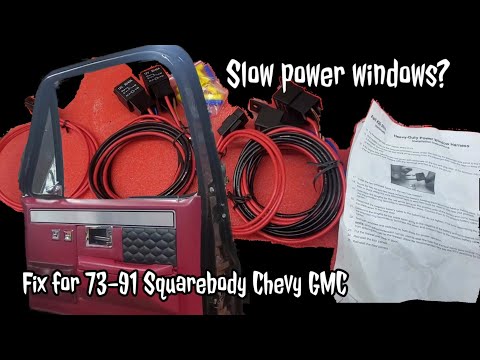

LMC Truck: Heavy-Duty Power Window Harness Installation with Kevin Tetz

Показать описание

Kevin Tetz leads you through the step-by-step installation of LMC Truck’s exclusive Heavy-Duty Power Window Harness. This DIY wiring project for 1977-1991 Chevy/GMC trucks and SUVs is a great upgrade that takes just a couple hours of time with basic tools and some typical electrical supplies.

The heavy-duty wiring harness is the ideal solution for the slow window motor in your Chevy, GMC Truck or SUV. Even with all other parts being new, the factory window motor can be slow because of the path the current needs to take. The Heavy-Duty Power Window Harness from LMC Truck draws power directly from your battery to the power window motor through an inline fuse, so this easy solution makes a significant difference in window speed.

The detailed instructions that come with the harness guide you through the full installation, but Kevin shows you some great common-sense wiring tips in this video, as well as the best way to get the wiring done for a clean installation, including a great coat hanger trick for pulling wires through tricky areas.

Subscribe to our LMC Truck YouTube channel for our latest updates and How-To guides.

Комментарии

0:14:57

0:14:57

0:11:42

0:11:42

0:00:37

0:00:37

0:00:32

0:00:32

0:00:55

0:00:55

0:11:01

0:11:01

0:00:49

0:00:49

0:11:09

0:11:09

0:09:57

0:09:57

0:02:18

0:02:18

0:07:06

0:07:06

0:03:39

0:03:39

0:17:48

0:17:48

0:10:45

0:10:45

0:09:40

0:09:40

0:00:59

0:00:59

0:13:46

0:13:46

0:00:25

0:00:25

0:05:10

0:05:10

0:21:09

0:21:09

0:27:27

0:27:27

0:00:23

0:00:23

0:01:26

0:01:26

0:01:50

0:01:50