filmov

tv

Recycling 3D Prints Back into Filament #3dprinting #recycle #filamentextruder

Показать описание

Recycling 3D Prints Back into Filament #3dprinting #recycle #filamentextruder

Turning 3D Print Waste into New Filament!

Now You Can Recycle Your 3D Prints Affordably*

Recycling 3D printed parts back into usable material! #3dprinting #3dprinter #recyling #reclaimed

3D print waste RECYCLED

Recycle your failed 3D prints! Make new filament at home.

Reusing 3D printer waste as arts material

Recycling Failed 3D Prints with a DIY Filament Extruder: Artme3D

Recycling 3D Prints and Waste Plastic into Filament (PET & PLA)

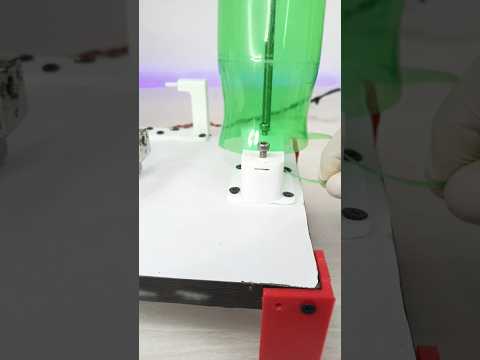

This machine turns plastic bottles into filament for 3D printing!

This is totally not a 3D Scam Right? RIGHT?

How to recycle 3D printed supports

How to recycle PLA 3D printing filament

Remelting PLA 3D Prints

BYE BYE 3D print waste

Melt your 3D Prints!

Recycling 3D Printer Scraps Into Something Amazing ♻️💀

PET Bottle Recycling: Waste to 3D Printing Filament

Transforming Waste Plastic Bottle into 3D Printed Masterpiece

Recycling 3d print scraps #3dprinting #diy #craft

Shredding scrap 3d printing filament for recycling ♻️#sustainability #3dprinting #3dprint #diy #fyp...

PLA Recycling! Please see description for more info #3dprinting #3dprinter

Recycle 3D Printing Waste AT HOME

Recycling my failed prints #3dprinting #halloween

Комментарии

0:01:00

0:01:00

0:12:48

0:12:48

0:29:10

0:29:10

0:00:10

0:00:10

0:00:32

0:00:32

0:09:03

0:09:03

0:00:14

0:00:14

0:20:10

0:20:10

0:39:13

0:39:13

0:00:54

0:00:54

0:11:56

0:11:56

0:01:01

0:01:01

0:01:00

0:01:00

0:05:20

0:05:20

0:00:25

0:00:25

0:08:41

0:08:41

0:01:00

0:01:00

0:17:37

0:17:37

0:00:31

0:00:31

0:00:23

0:00:23

0:00:52

0:00:52

0:01:01

0:01:01

0:21:40

0:21:40

0:00:08

0:00:08