filmov

tv

4 EASY Steps to Inventory Improvement + An Easy Diagnostic

Показать описание

Managing inventory effectively can be a constant struggle for most organisations.

So here is a simple 4 Step process to check your inventory health….and improve it!

TIMESTAMPS (in case you want to skip) 👇

0:00 Intro

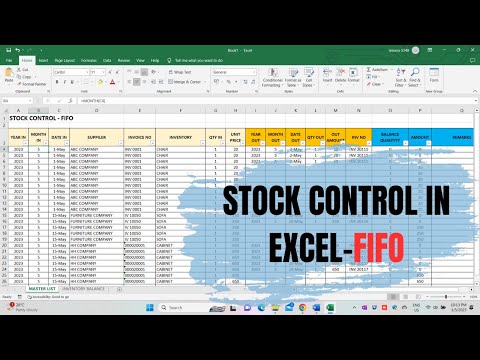

Step 1: ASSESS YOUR CURRENT INVENTORY

0:48 Check Your Product Availability

1:25 Strategic ABC Segmentation

2:11 Review Excess and Obsolete Stock

3:09 Step 2: MAKE A PLAN FOR EVERY SKU AND DOCUMENT IT!

4:07 Step 3: REVIEW KPIs

4:57 Step 4: SELECT THE RIGHT SOFTWARE

6:22 Summary

6:48 Outro

🟨 Don't forget 🟨 to SUBSCRIBE.

New Supply Chain videos every Wednesday.

AND 🙋

Do Please comment with your thoughts, suggestions and any questions

---------------------------------------------------------------------------------------------------------------------------------------------------------

Effective inventory management can be challenging, as businesses often grapple with the following common problems:

1. **Excessive Stock**: Overstocking is a substantial issue, trapping capital and heightening risks related to damage and obsolescence. Mastering the delicate balance between inventory levels and anticipated demand is key to avoiding this predicament.

2. **Stockouts**: The flip side of overstocking is the challenge of stockouts. These situations represent missed sales and can damage relationships with customers. Quick response strategies and safety stock management can help mitigate this risk.

3. **Demand Forecasting Inaccuracies**: In a fluctuating market, maintaining accuracy in demand forecasting is a formidable challenge. Misestimations can lead to either overstocking or stockouts, underscoring the importance of robust forecasting methods.

4. **Inadequate Real-Time Visibility**: Many organizations lack a real-time, granular view of their inventory status. This deficiency can lead to inaccurate data and a slowed response to market changes, making system upgrades essential.

5. **Operational Inefficiencies**: Arising from outdated inventory management systems, manual processes, or lack of integration, operational inefficiencies can cost time and money. Addressing these issues requires strategic system enhancement and process refinement.

Surmounting these obstacles requires strategic foresight, a willingness to leverage technology, and a commitment to continuous process improvement. By addressing these concerns, businesses can optimize their operations, boosting customer satisfaction and their bottom line.

#inventory #inventorymanagement #workingcapital

So here is a simple 4 Step process to check your inventory health….and improve it!

TIMESTAMPS (in case you want to skip) 👇

0:00 Intro

Step 1: ASSESS YOUR CURRENT INVENTORY

0:48 Check Your Product Availability

1:25 Strategic ABC Segmentation

2:11 Review Excess and Obsolete Stock

3:09 Step 2: MAKE A PLAN FOR EVERY SKU AND DOCUMENT IT!

4:07 Step 3: REVIEW KPIs

4:57 Step 4: SELECT THE RIGHT SOFTWARE

6:22 Summary

6:48 Outro

🟨 Don't forget 🟨 to SUBSCRIBE.

New Supply Chain videos every Wednesday.

AND 🙋

Do Please comment with your thoughts, suggestions and any questions

---------------------------------------------------------------------------------------------------------------------------------------------------------

Effective inventory management can be challenging, as businesses often grapple with the following common problems:

1. **Excessive Stock**: Overstocking is a substantial issue, trapping capital and heightening risks related to damage and obsolescence. Mastering the delicate balance between inventory levels and anticipated demand is key to avoiding this predicament.

2. **Stockouts**: The flip side of overstocking is the challenge of stockouts. These situations represent missed sales and can damage relationships with customers. Quick response strategies and safety stock management can help mitigate this risk.

3. **Demand Forecasting Inaccuracies**: In a fluctuating market, maintaining accuracy in demand forecasting is a formidable challenge. Misestimations can lead to either overstocking or stockouts, underscoring the importance of robust forecasting methods.

4. **Inadequate Real-Time Visibility**: Many organizations lack a real-time, granular view of their inventory status. This deficiency can lead to inaccurate data and a slowed response to market changes, making system upgrades essential.

5. **Operational Inefficiencies**: Arising from outdated inventory management systems, manual processes, or lack of integration, operational inefficiencies can cost time and money. Addressing these issues requires strategic system enhancement and process refinement.

Surmounting these obstacles requires strategic foresight, a willingness to leverage technology, and a commitment to continuous process improvement. By addressing these concerns, businesses can optimize their operations, boosting customer satisfaction and their bottom line.

#inventory #inventorymanagement #workingcapital

Комментарии

0:07:20

0:07:20

0:02:29

0:02:29

0:00:51

0:00:51

0:06:00

0:06:00

0:07:55

0:07:55

0:00:22

0:00:22

0:01:59

0:01:59

0:08:45

0:08:45

0:16:43

0:16:43

0:07:15

0:07:15

0:00:45

0:00:45

0:02:04

0:02:04

0:10:35

0:10:35

0:11:36

0:11:36

0:12:39

0:12:39

0:25:31

0:25:31

0:00:23

0:00:23

0:00:11

0:00:11

0:00:40

0:00:40

0:06:12

0:06:12

0:09:47

0:09:47

0:13:02

0:13:02

0:21:57

0:21:57

0:00:40

0:00:40