filmov

tv

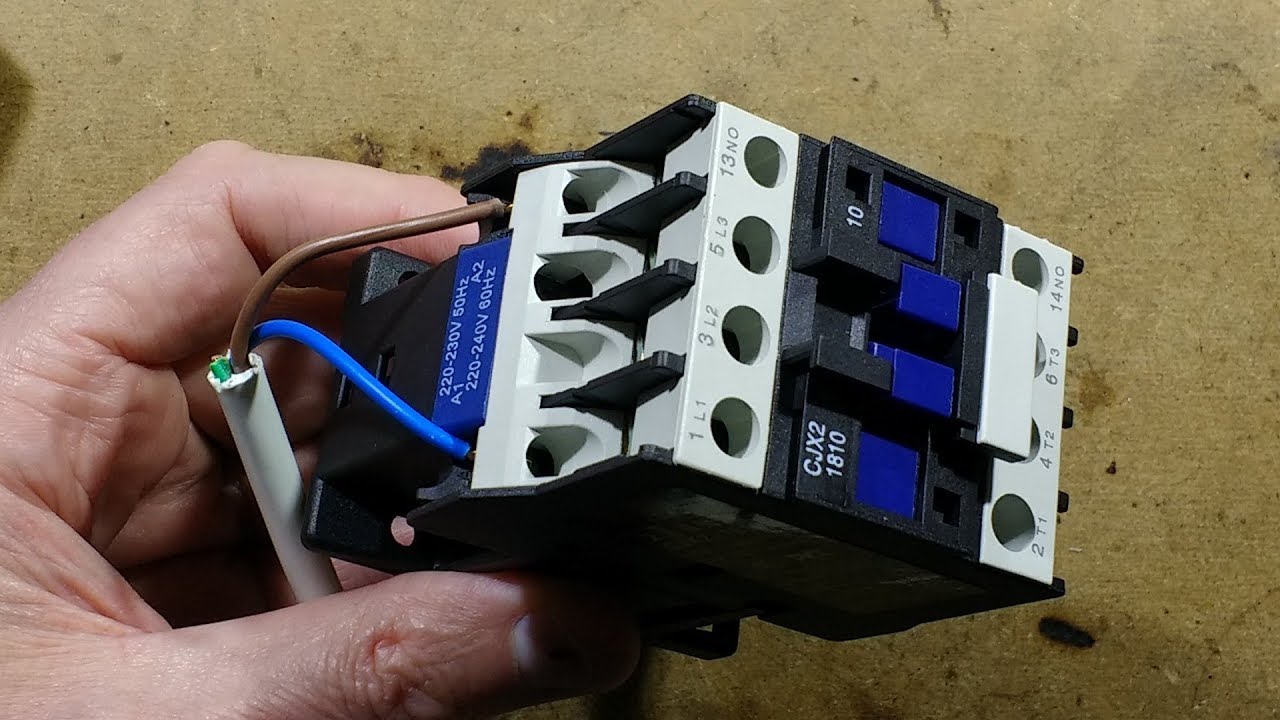

eBay CJX2 industrial contactor teardown.

Показать описание

Here's a general purpose eBay search link:-

If you enjoy these videos you can help support the channel with a dollar for coffee, cookies and random gadgets for disassembly at:-

This also keeps the channel independent of YouTube's advertising algorithms allowing it to be a bit more dangerous and naughty.

If you enjoy these videos you can help support the channel with a dollar for coffee, cookies and random gadgets for disassembly at:-

This also keeps the channel independent of YouTube's advertising algorithms allowing it to be a bit more dangerous and naughty.

eBay CJX2 industrial contactor teardown.

1257. CJX2-18 MAGNETIC CONTACTOR shown and removing of its SOLENOID COIL

1263. CJX2-18 MAGNETIC CONTACTOR shown and removing of its IRON CORE

Teardown Tuesday Episode 18: Contactor

Magnetic contactor Teardown.

Magnetic Contactor Teardown

1265. CJX2-18 MAGNETIC CONTACTOR shown of its 2 A2 and 1 A1 Terminal

Contactor CJX2-1201 110V 50/60 Hz single Poles Normally Closed

Contactor Tear Down

CONTACTOR PARTS

ZJSHUYI What does the AC contactor cjx2-3210 represent. www.shuyitop.com;#contactor #ACcontactor

contactor operations by Ibrahim 220v 18A for 2hp motor

CJX2s 120 AC Contactor with Lower Power Consumption

Schneider magnetic contactor! How to open/repair magnetic contactor

#Contactor #Dismantling

AC contactor CJX2s reliability test

CJX2

Jiuce |Ac contactor CJX2 18

Magnetic contactor Repair disassemble & assembled

GEYA CJX2-4011 5011 6511 Industrial Magnetic Contactor

#OPENING A #24 VDC #CONTACTOR #TEARDOWN & #REPAIRING #TRICKS #schneider #hindi

Magnetic contactor 25Amps 220Volts#Chint# 1NO#NC1-1810#Retedoperatedcurrent#18Amps#440Volts

Magnetic contactor sparking #shorts

CJX2-K series AC Contactor

Комментарии

0:18:40

0:18:40

0:00:14

0:00:14

0:00:14

0:00:14

0:12:43

0:12:43

0:10:39

0:10:39

0:13:19

0:13:19

0:00:14

0:00:14

0:00:11

0:00:11

0:01:40

0:01:40

0:00:22

0:00:22

0:00:14

0:00:14

0:00:12

0:00:12

0:01:00

0:01:00

0:12:04

0:12:04

0:00:26

0:00:26

0:00:27

0:00:27

0:00:32

0:00:32

0:00:15

0:00:15

0:23:09

0:23:09

0:00:18

0:00:18

0:09:29

0:09:29

0:00:16

0:00:16

0:00:06

0:00:06

0:00:23

0:00:23