filmov

tv

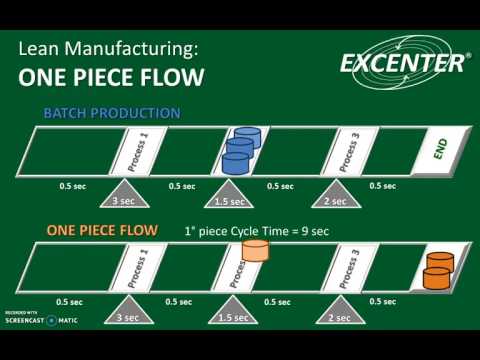

Lean Manufacturing One Piece Flow vs. Mass Production Paper Airplane Simulation (Lean Tip 005)

Показать описание

See how to transform slow and wasteful mass production into lean one piece flow in this simple and fun paper airplane simulation.

★ OUR FAVORITE LEAN COURSES ★

!!!---LEARN THE FUNDAMENTALS OF LEAN---!!!

★ MORE RECOMMENDED VIDEOS FOR YOU ★

How Lean Manufacturing Lets You Eat Mor Chikin At Chick-Fil-A -

✉ JOIN THE MAILING LIST ✉

⚑ SUBSCRIBE TO OUR CHANNEL ⚑

ツ CONNECT WITH LEAN SMARTS ツ

Leave a comment on this video and it'll get a response. Or you can connect with us on different social platforms too:

.: MORE ABOUT DANIEL PERSONALLY :.

-----------------------------------------------------------------------------

Thank you for watching - I really appreciate it :)

Cheers,

Daniel | Lean Smarts

★ OUR FAVORITE LEAN COURSES ★

!!!---LEARN THE FUNDAMENTALS OF LEAN---!!!

★ MORE RECOMMENDED VIDEOS FOR YOU ★

How Lean Manufacturing Lets You Eat Mor Chikin At Chick-Fil-A -

✉ JOIN THE MAILING LIST ✉

⚑ SUBSCRIBE TO OUR CHANNEL ⚑

ツ CONNECT WITH LEAN SMARTS ツ

Leave a comment on this video and it'll get a response. Or you can connect with us on different social platforms too:

.: MORE ABOUT DANIEL PERSONALLY :.

-----------------------------------------------------------------------------

Thank you for watching - I really appreciate it :)

Cheers,

Daniel | Lean Smarts

Lean Manufacturing One Piece Flow vs. Mass Production Paper Airplane Simulation (Lean Tip 005)

ONE PIECE FLOW versus BATCH PRODUCTION - Lean Manufacturing

Lean Manufacturing : What is Single Piece Flow?

Lean - One-Piece Flow is Simple (Voiceover Version)

Chaku Chaku - One Piece Flow

Batch Processing v One Piece Flow

Batch vs. One-Piece Flow Production

What exactly is one piece flow in Lean Manufacturing?

One Piece Flow

Lean Manufacturing One Piece Flow Solid Wood Milling

One Piece Flow Vs Batch [ ONE PIECE FLOW Vs MASS PRODUCTION ] One piece flow lean manufacturing

One-Piece Flow | Lean Principles | Ryan Tierney

ONE PIECE FLOW versus BATCH PRODUCTION Lean Manufacturing

Barksdale Series 8000 - One-Piece-Flow

Four Principles Lean Management - Get Lean in 90 Seconds

Lean Basics: one piece flow simulation at Lean Factory Vietnam

THE BEST -Single Piece Flow V.S. Batch example - Lean Manufacturing

Watch This One Piece Flow vs. Mass Production Envelope Stuffing Lean Thinking Simulation

LEAN DEVELOPMENT - ONE PIECE FLOW

Batch vs One Piece Flow Manufacturing

One Piece Flow Production - S2 E19

Lean - One-Piece Flow is Simple

One Piece Flow Demonstration- S1 E2

Lean U-Cell Implementation

Комментарии

0:07:46

0:07:46

0:00:47

0:00:47

0:07:57

0:07:57

0:04:42

0:04:42

0:00:17

0:00:17

0:00:43

0:00:43

0:01:13

0:01:13

0:02:40

0:02:40

0:00:24

0:00:24

0:01:13

0:01:13

0:05:47

0:05:47

0:26:02

0:26:02

0:00:47

0:00:47

0:01:50

0:01:50

0:01:57

0:01:57

0:02:44

0:02:44

0:02:28

0:02:28

0:11:39

0:11:39

0:01:12

0:01:12

0:02:36

0:02:36

0:08:48

0:08:48

0:04:42

0:04:42

0:09:15

0:09:15

0:03:08

0:03:08