filmov

tv

Building a Spot Welder from a Microwave Transformer!

Показать описание

I think this project may have been on my list since I was in high school: rewiring a microwave oven transformer into a potent spot welder. I came up with an Arduino-controlled system that lets me do everything from tacking shim stock together to welding on nuts and studs. This first part is just the assembly and testing. The next part will be a more detailed look at how I machined the parts. I'll upload all of electrical schematics and code up to my Patreon as a freebie!

Building a spot welder from an old microwave.

DIY Spot welder build - Cheapest out there! Part 1/2

How to Build a Spot Welder out of an Old Microwave | Remake Project

DIY spot welder machine #howtomake

Make a Spot Welder for Cheap!!

Battery tab Spot Welder.. saelectric #trendingshorts #reels #shorts #short #shortvideo#viralshort

🔥 DIY Battery Spot Welder! 🔥

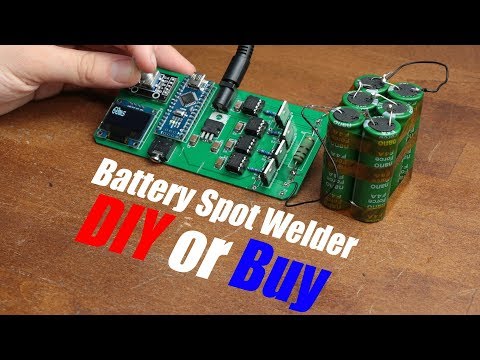

Battery Spot Welder (CD Welder) || DIY or Buy

How to Weld Copper to Copper with Special Copper Flux | Boost Your Spot Welding Power! Part 2

Home-made spot welder (very powerful)

spot tool #shorts #youtubeshorts

No need for spot welding machine, easily solder nickel sheet to 18650 lithium battery #flux

Spot Welding 18650 Cell

Battery spot welder

18650 Battery Tab Spot Welding Machine using Microwave Transformer #shorts #short

⚡ Mini spot welder with interchangeable battery!

DIY Spot Welding Machine

#spotwelder DIY spot welder

🔥 Build a Spot Welder Using Just a Battery! 🔥

⚡ DIY Battery Spot Welder! 🔥

BUILD A SPOT WELDING MACHINE TO SAVE MONEY

DIY spot welding

A little flux makes spot welding 18650 lithium batteries fast & safe #flux #18650battery #solder...

BUILD A DIY SPOT WELDING MACHINE

Комментарии

0:07:25

0:07:25

0:09:20

0:09:20

0:08:01

0:08:01

0:00:39

0:00:39

0:08:51

0:08:51

0:00:54

0:00:54

0:00:57

0:00:57

0:08:03

0:08:03

1:41:10

1:41:10

0:16:57

0:16:57

0:00:16

0:00:16

0:00:33

0:00:33

0:00:13

0:00:13

0:00:22

0:00:22

0:00:46

0:00:46

0:00:59

0:00:59

0:03:01

0:03:01

0:00:57

0:00:57

0:01:00

0:01:00

0:00:58

0:00:58

0:14:11

0:14:11

0:00:09

0:00:09

0:00:15

0:00:15

0:10:23

0:10:23