filmov

tv

PCB Manufacturing and Assembly Process in Factory | How Printed Circuit Boards are Made | Production

Показать описание

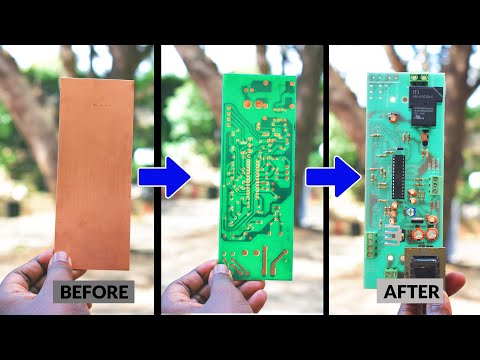

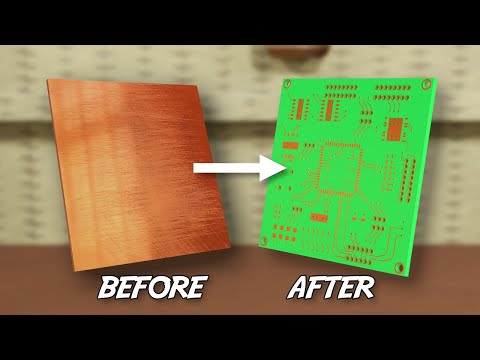

In this factory tour video, we'll unbox the PCB making factory. Here the PCB making process starts with FR-4 or other materials depends on PCB type. The PCB or Printed Circuit Board making process consists of several steps and to make perfect pcb requires years of experience and technology. So, enjoy this video.

PCB 101 Academy - Learn how printed circuit boards are assembled

PCB Manufacturing and Assembly Process in Factory | How Printed Circuit Boards are Made | Production

PCB Manufacture and PCB Assembly inside PCB Factory China - PCBWay

Multi-layer PCB Manufacturing Process | Full Movie

PCB Manufacturing Process , PCB making

How much do you know about PCB manufacturing process?

How much do you know about PCB manufacturing process?

Inside China's Leading PCB Assembly Factory | Discover Our State-of-the-Art Manufacturing Proce...

SMT Vs THT PCB Assembly Process - Differences Explained

Inside the Professional PCB Assembly Process at a Leading Chinese Company

How It's Made: Multilayer PCB Manufacturing Insight

Trailer - PCB Manufacturing and Assembly Process (PCBWay New Factory)

PCB Assembly Process: Inspection

PCB Assembly Process: Plated Through Hole Component Insertion

PCBMay: Our PCB Production & Assembly Process | Meet the Team & Clients!

Inside a PCB Soldering Factory - in China

Inside a Huge PCB Factory

Large-scale PCB production process--PCB assembly

What is a PCB?

What are PCBs? || How do PCBs Work?

SMT Assembly Process | PCB Assembly Process | Production of Electronics Circuit | Learn in 5 Minutes

How SMT line works? Watch electronics manufacturing process in our PCB assembly line

How PCB is Made in China - NextPCB Factory Visit || PCB Manufacturing & Assembly Process

PCB Assembly Process: Reflow Soldering Process

Комментарии

0:06:19

0:06:19

0:08:53

0:08:53

0:13:10

0:13:10

0:34:04

0:34:04

0:04:22

0:04:22

0:00:18

0:00:18

0:00:15

0:00:15

0:01:17

0:01:17

0:02:56

0:02:56

0:14:08

0:14:08

0:19:56

0:19:56

0:02:11

0:02:11

0:00:15

0:00:15

0:00:15

0:00:15

0:02:31

0:02:31

0:18:10

0:18:10

0:26:49

0:26:49

0:00:51

0:00:51

0:06:08

0:06:08

0:10:27

0:10:27

0:05:38

0:05:38

0:04:00

0:04:00

0:07:45

0:07:45

0:00:15

0:00:15