filmov

tv

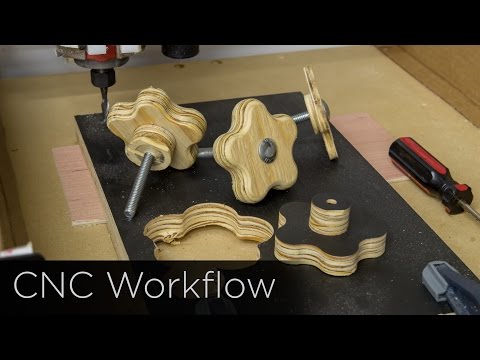

CNC Workflow: SketchUp, MakerCam, Universal Gcode Sender - 191

Показать описание

Subscribe for new videos every week. The actual information that a CNC machine uses to determine where to move is called G-code. There are many ways to not only transfer the G-code to the CNC but also to actually generate the G-code. Today I’m going to show you a simple workflow that can be used with SketchUp, MakerCam, and Universal G-code Sender.

----------

This is what I do for a living so if you would like to show your support without spending a dime please watch, comment, or share anything on my website. Viewing everything from my website goes a long way in helping support what I do. Thanks!

Social links:

Tools in my shop (affiliate links):

Social links:

Mailing Address:

PO Box 33

Mathiston, MS 39752

Want to help support what I do? Here's what you can do:

----------

This is what I do for a living so if you would like to show your support without spending a dime please watch, comment, or share anything on my website. Viewing everything from my website goes a long way in helping support what I do. Thanks!

Social links:

Tools in my shop (affiliate links):

Social links:

Mailing Address:

PO Box 33

Mathiston, MS 39752

Want to help support what I do? Here's what you can do:

CNC Workflow: SketchUp, MakerCam, Universal Gcode Sender - 191

CNC Workflow: Sketchup, Makercam, GRBL Controller

Tutorial: Gerando imagem SketchUp, MakerCam.

SketchUp tutorial - frezowanie na maszynie CNC

Makercam not working

Shapeoko 2: How to Setup Tabs in MakerCAM

makercam super simple quick start tutorial 6jun2015

CNC Design to Cut in 5 minutes w/ GRBLweb (process workflow)

Réglage GRBL

DIY CNC - Tuning Up the GRBL Settings

gcodesenderBrasil - O início de um software para brasileiros.

De Sketchup a Cnc con SketchUcam: Dibujo, Herramientas básicas y generación de código GRBL #3

How to Use GRBLWeb with your CNC

My shapeoko settings

De Sketchup a Cnc con SketchUcam: Configuración área de trabajo #2

DIY CNC Homemade - Universal Gcode Sender Configuration

Tutorial Cad Cam Usinagem CNC com Arduino

How To: Setup Grbl firmware, Drivers & Universal G-Code Sender

CNC Modding 101 Programs

First Test Of My DIY CNC Running Grbl, Universal Gcode Sender

OpenSCAM Tutorial for Verifying HeeksCNC output

Universal G Code Sender UGS

Test CNC GRBL

GRBL custom board

Комментарии

0:12:21

0:12:21

0:06:13

0:06:13

0:06:51

0:06:51

0:14:55

0:14:55

0:01:23

0:01:23

0:03:22

0:03:22

0:04:03

0:04:03

0:05:21

0:05:21

0:00:24

0:00:24

0:05:34

0:05:34

0:09:46

0:09:46

0:08:55

0:08:55

0:05:06

0:05:06

0:23:04

0:23:04

0:10:21

0:10:21

0:07:29

0:07:29

0:09:15

0:09:15

0:16:12

0:16:12

0:17:30

0:17:30

0:06:23

0:06:23

0:03:16

0:03:16

0:14:57

0:14:57

0:01:01

0:01:01

0:00:21

0:00:21