filmov

tv

Is Cheap 3D Filament Bad?

Показать описание

I tested the cheapest filaments that I could find to answer the question if cheap 3D filament is bad.

------------------------------------------------------------------------------------

Products used in this Video:

Elegoo PLA:

Creality PLA:

Polymaker Polyterra PLA (Affiliate Link):

Geeetech PLA (Affiliate Link):

SunLu PLA + (Affiliate Link):

------------------------------------------------------------------------------------

Products used in this Video:

Elegoo PLA:

Creality PLA:

Polymaker Polyterra PLA (Affiliate Link):

Geeetech PLA (Affiliate Link):

SunLu PLA + (Affiliate Link):

Is Cheap 3D Filament Bad?

Is Cheap Filament Bad for 3D Printing? NEED TO KNOW

CHEAP 3D Printing Filament: The honest TRUTH

What filament should you buy? Is cheap filament bad?

How to get Cheap 3D Printer Filament #3dprinting #3dprintingbusiness #3dprintingfarm #filament

Cheapest vs. Most Expensive 3D Printing Filament #shorts

How bad is a $95 3D Printer??

How bad is a $69 3D Printer?

Is this good filament?

Reviving 7yr old filament with a $20 Dehydrator

I Bought the 5 Cheapest 3D Printers on Amazon

The best 3D printing filament… affordable, reliable, and on plastic spools… 😏

Expensive vs Cheap 3D Printer 💲

Testing Cheap vs. Expensive 3D Printer!

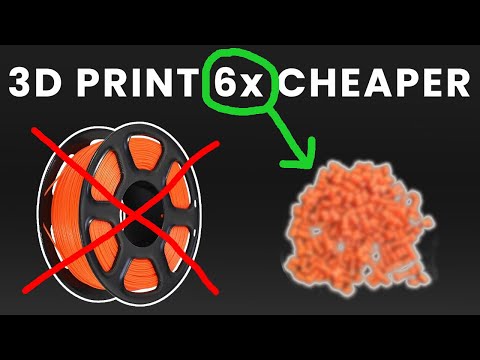

Stop Buying Filament, Use This 6x CHEAPER Alternative instead

The 3D Filament Tier List! Which Should YOU Use?

How to quickly check if you PLA filament is wet

Dry vs Moist TPU in 3D Printing

$100 3D Printer - The Ender 3

A Hassle-Free 3D Printer

Do You ACTUALLY Need To Dry Your Filament? (Probably Not)

Bambu A1 mini VS X1 Carbon - MY THOUGHTS #3dprinting

Affordable filament made in Europe by Aurapol

NEVER use cheap filament

Комментарии

0:13:43

0:13:43

0:04:49

0:04:49

0:08:15

0:08:15

0:06:20

0:06:20

0:00:28

0:00:28

0:00:44

0:00:44

0:08:10

0:08:10

0:04:20

0:04:20

0:00:43

0:00:43

0:11:17

0:11:17

0:12:32

0:12:32

0:00:21

0:00:21

0:00:41

0:00:41

0:00:25

0:00:25

0:12:43

0:12:43

0:44:34

0:44:34

0:00:55

0:00:55

0:01:00

0:01:00

0:00:10

0:00:10

0:00:22

0:00:22

0:24:50

0:24:50

0:01:00

0:01:00

0:01:00

0:01:00

0:00:10

0:00:10