filmov

tv

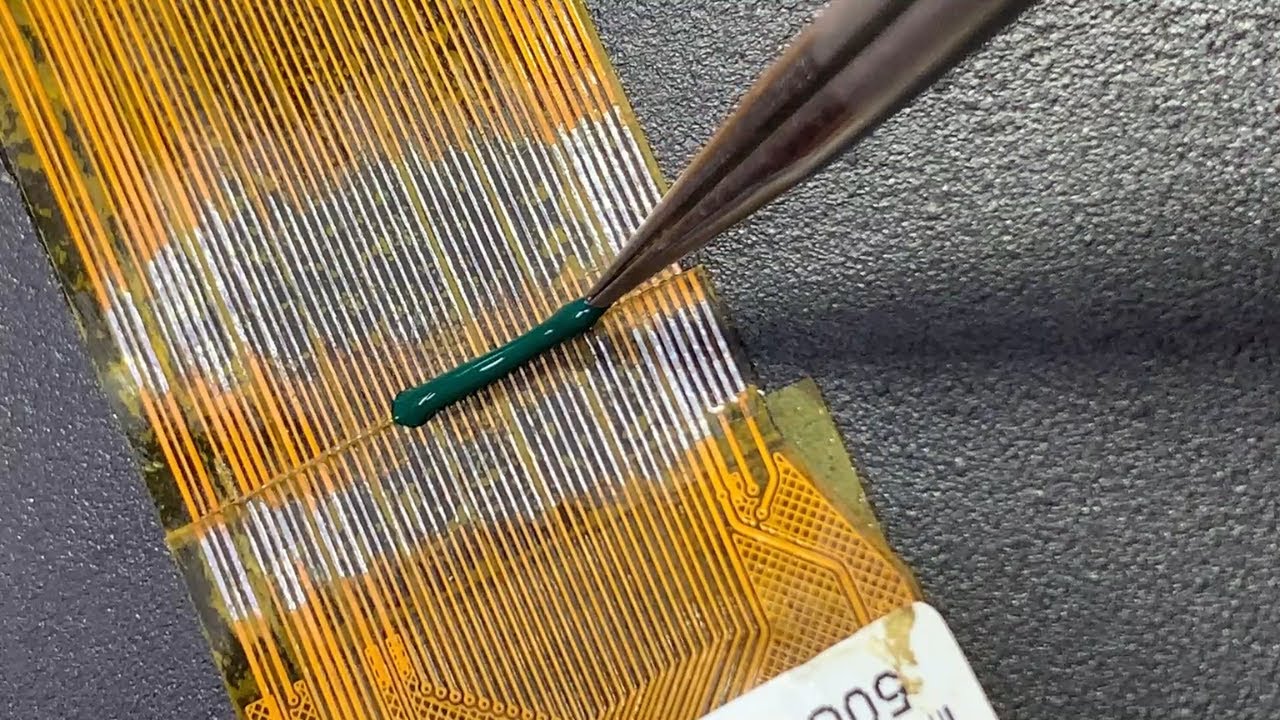

Broken Flex Repair #mobilerepair #electronics #microsoldering

Показать описание

Broken Flex Repair #mobilerepair #electronics #microsoldering

donate for grow community increase videos quality etc

donate for grow community increase videos quality etc

Broken Flex Repair #mobilerepair #technology

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #mobilerepair #technology

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair Tutorial

Broken Flex Repair #mobilerepair #soldering

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #technology #mobilerepair

Broken Flex Repair #mobilerepair #technology

Broken Lcd Flex Repair #technology #mobilerepair

Broken Flex Repair #mobilerepair #electronics #microsoldering

Broken Display Flex #technology #mobilerepair

Broken Flex Repair #electronics #microsoldering #mobilerepair

#shorts mobile lcd backlight broken flex repair #mobilerepairing

Broken Flex Repair #mobilerepair #electronics #microsoldering

Broken Flex Repair #mobilerepair #electronics

Broken Flex Repair #electronics #microsoldering #mobilerepair

How to Repair Broken or Torn Flex , Flexible Cables #shorts

Broken Flex Repair #mobilerepair #technology

Broken Flex Repair #technology #mobilerepair

Комментарии

0:00:59

0:00:59

0:00:50

0:00:50

0:00:55

0:00:55

0:00:57

0:00:57

0:00:35

0:00:35

0:00:32

0:00:32

0:01:00

0:01:00

0:00:45

0:00:45

0:00:58

0:00:58

0:00:47

0:00:47

0:00:59

0:00:59

0:00:55

0:00:55

0:00:56

0:00:56

0:00:52

0:00:52

0:09:02

0:09:02

0:00:55

0:00:55

0:00:49

0:00:49

0:00:31

0:00:31

0:10:54

0:10:54

0:00:48

0:00:48

0:00:16

0:00:16

0:00:26

0:00:26

0:00:59

0:00:59

0:00:57

0:00:57