filmov

tv

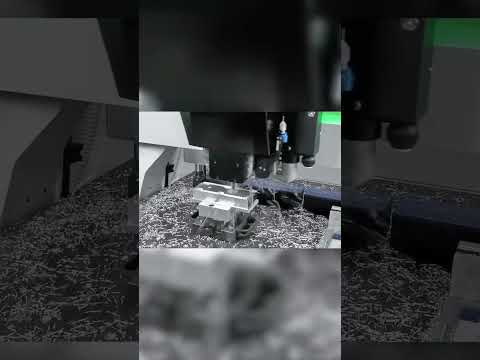

How These INSANELY Precise Cuts Are Made

Показать описание

GF CUT P 550 Pro EDM! Electrical Discharge Machining or "EDM" is an unique yet different way to machine from your traditional CNC Machines. Having .0001 tolerance on a part is mind boggling, and doing it at a 20 degree angle is even more impressive!

Subscribe to our podcast channel:

@titansofcncpodcast

Join this channel to get access to perks:

0:00 EDM Machining on GF CUT P 550 Pro

1:37 How to Program an EDM Machine

4:12 20 Degree Angle Wire EDM Machining

Help us fund FREE Education by purchasing tools seen in our videos here:

Create your free CNCEXPERT profile here:

FREE CNC Machining Academy:

FREE Aerospace Academy:

FREE Grinding Academy:

___

___

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

___

___

THANK YOU to our Partners who make this content possible:

#Machining #Machinist #Engineering

Subscribe to our podcast channel:

@titansofcncpodcast

Join this channel to get access to perks:

0:00 EDM Machining on GF CUT P 550 Pro

1:37 How to Program an EDM Machine

4:12 20 Degree Angle Wire EDM Machining

Help us fund FREE Education by purchasing tools seen in our videos here:

Create your free CNCEXPERT profile here:

FREE CNC Machining Academy:

FREE Aerospace Academy:

FREE Grinding Academy:

___

___

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

___

___

THANK YOU to our Partners who make this content possible:

#Machining #Machinist #Engineering

How These INSANELY Precise Cuts Are Made

INSANE Tapered Cut on Wire EDM #shorts

INSANELY Fast Precision😲

THE MOST INSANE Precision Machining. #cncmachining #cncmilling #cnc

The MOST INSANE Steel Cut in a CNC Machine!!

The INSANE Precision of The National Institute of Standards and Technology

Used syringe under the microscope is insane (real!)

Amazing Machines Operating At An INSANE LEVEL

Amazing Machines Operating At An Insane level - P9

Insane gear cutting process 🤯 #engineering #buisness

Ultimate Beef Cutting Technique for Insane Flavor and Precision in 2024 @Independentmeatscutting007

Wire EDM is insane! Seamless Precision Machining

50 Amazing Machines operating at insane level

This is an INSANE CNC Machine Setup

Amazing Machines Operating At An Insane level - P6

Learn 5 Brazilian skills that look insane

Insanely Fast CNC Machining Inconel 625 w/ Ceramic End Mills | Pushing UMC-750SS to the Limit

Insane Proof Ancient people Had MACHINERY!

Amazing Machines Operating At An Insane level - P7

The NEW Wilson basketball is INSANE!!

BIG longboard crash #longboard #extreme #sport #downhill #skateboard #fail #crash #insane #shorts

Most Satisfying Machines And Ingenious Tools Operating on Insane Level !

100 Amazing Agriculture Machines Operating At An INSANE LEVEL

'Pushing the limits of precision! Check out these insanely thin tile cuts. #tools #tilecutter #...

Комментарии

0:04:47

0:04:47

0:00:37

0:00:37

0:00:32

0:00:32

0:00:19

0:00:19

0:00:10

0:00:10

0:14:54

0:14:54

0:00:38

0:00:38

0:29:33

0:29:33

0:09:56

0:09:56

0:00:13

0:00:13

0:00:14

0:00:14

0:00:39

0:00:39

0:08:24

0:08:24

0:00:17

0:00:17

0:16:56

0:16:56

0:00:57

0:00:57

0:08:54

0:08:54

0:00:45

0:00:45

0:13:38

0:13:38

0:00:56

0:00:56

0:00:14

0:00:14

0:32:58

0:32:58

0:21:05

0:21:05

0:00:14

0:00:14