filmov

tv

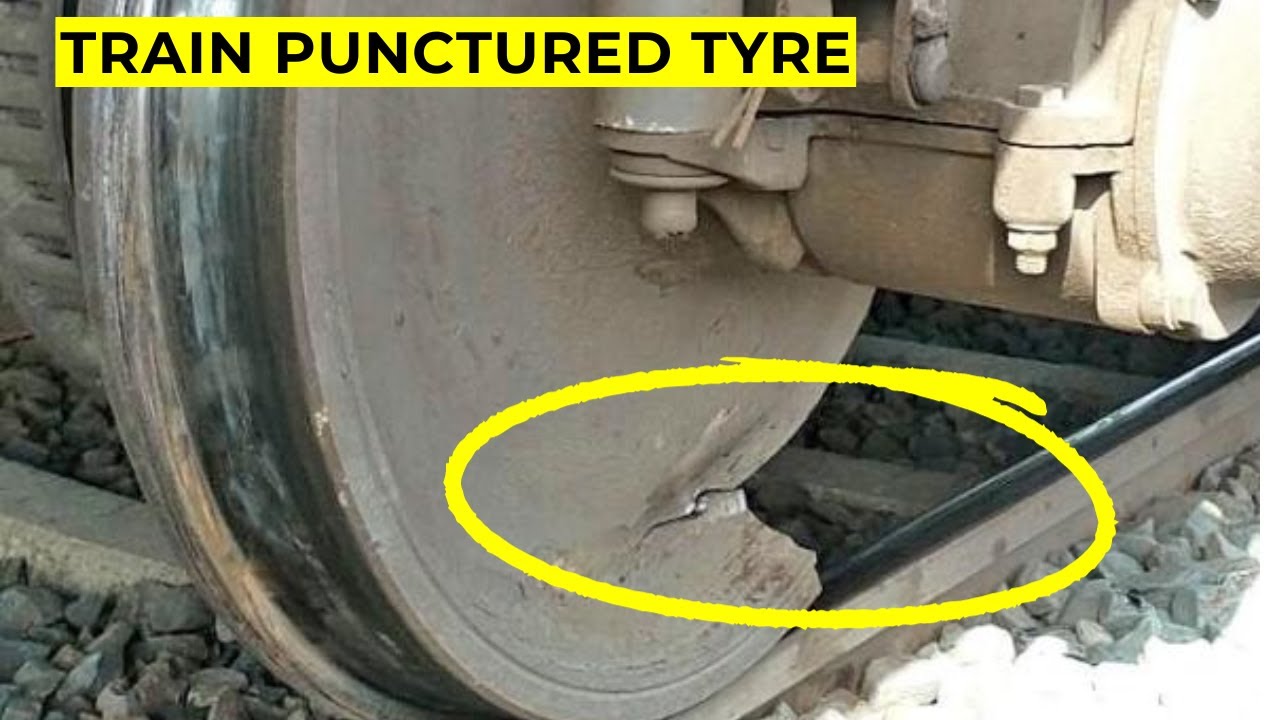

Punctured Train Tire Replacement Procedure | Causes and Consequences | Precision and Safety

Показать описание

Trains don't have conventional rubber tires; instead, they use specialized steel wheels often referred to as "train tires." These wheels are robust and designed to handle massive loads and high speeds. A punctured train tire occurs when there's damage or a hole on the wheel's surface, which can significantly impact the train's performance, safety, and overall efficiency.

You might be wondering how punctured train tire happens. Well, there are several factors at play. Debris, such as rocks, metal fragments, or other foreign objects on the tracks, can pose a significant threat. This is particularly common in areas with heavy freight traffic. Extreme weather conditions, like severe cold or intense heat, can also contribute to tire damage over time. Additionally, the continuous wear and tear from regular train operations can gradually lead to punctures.

Now, let's delve into the intricate process of replacing a punctured train tire. Please note that this is a highly specialized procedure carried out by trained professionals using specialized equipment.

The initial step involves identifying the punctured tire. Train maintenance crews perform routine inspections to detect damaged or irregular tires.

To replace a tire, the train must be lifted securely and safely off the ground. Specialized equipment, such as jacks or cranes, is used for this critical task. The wheelset that needs attention is isolated and lifted away from the rails.

You might be wondering how punctured train tire happens. Well, there are several factors at play. Debris, such as rocks, metal fragments, or other foreign objects on the tracks, can pose a significant threat. This is particularly common in areas with heavy freight traffic. Extreme weather conditions, like severe cold or intense heat, can also contribute to tire damage over time. Additionally, the continuous wear and tear from regular train operations can gradually lead to punctures.

Now, let's delve into the intricate process of replacing a punctured train tire. Please note that this is a highly specialized procedure carried out by trained professionals using specialized equipment.

The initial step involves identifying the punctured tire. Train maintenance crews perform routine inspections to detect damaged or irregular tires.

To replace a tire, the train must be lifted securely and safely off the ground. Specialized equipment, such as jacks or cranes, is used for this critical task. The wheelset that needs attention is isolated and lifted away from the rails.

Комментарии

0:04:17

0:04:17

0:00:23

0:00:23

0:00:24

0:00:24

0:00:23

0:00:23

0:00:25

0:00:25

0:00:23

0:00:23

0:08:47

0:08:47

0:00:59

0:00:59

0:00:59

0:00:59

0:06:55

0:06:55

0:05:59

0:05:59

0:06:55

0:06:55

0:00:14

0:00:14

0:05:59

0:05:59

0:08:12

0:08:12

0:07:50

0:07:50

0:10:38

0:10:38

0:02:50

0:02:50

0:05:47

0:05:47

0:07:24

0:07:24

0:07:05

0:07:05

0:20:32

0:20:32

0:12:11

0:12:11

0:14:39

0:14:39