filmov

tv

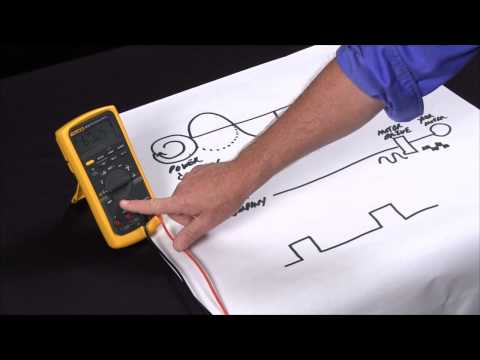

Using Fluke Meter to Test Air Compressor Motor Capacitors & opening up my SIP One Way Check valve. ⚡

Показать описание

In this video I start to investigate why my SIP air compressor keeps tripping the overload breaker. I test both the start and run capacitors with a Fluke 77 IV multimeter which has capacitance testing. ⬇️💥⬇️ Links Below & Donations ⬇️💥⬇️ These turn out to be ok so it's off with the drive belt and onto the one way check valve to see if that's working.

⚡Useful Tools. Some Used In This Video

⚡Coats and Gaiters is a participant of the Amazon Influencer Program.

I may earn a small commission with my affiliate links, though the prices paid are no higher but they do help me fund this channel.

⬇️Timecodes

00:00 Introduction

00:57 Opening up the Capacitor Box

02:24 Why do motors use capacitors?

04:08 Using a Fluke 77 to test the capacitors

04:52 Testing the Start capacitor

07:37 Testing the Run capacitor

09:06 A word of warning on replacing capacitors

10:23 Testing motor with drive belt removed

11:43 Creating an air leak

12:35 Check valve leaking continuously

13:41 Opening up the check valve

14:52 Photographs of parts

15:22 Still left puzzled !!!

17:14 Compressor seems to be working

17:52 Credits

🎁 Donations to help my Channel Grow 🎁

📹Some Of The Equipment Used To Create This Video:

1️⃣ Vegas 18 Pro Video Editing Software for the PC

⚡Other Social Media Links For Coats and Gaiters

Disclaimer:

This video only contains tips and my personal methods that could be helpful when carrying out home car repairs or replacing parts. Coats & Gaiters is not liable for any harm, injury or property damage incurred while carrying out such repairs or replacements, that are a result of incorrect use or misinterpretation of the provided information. This video is for informational purposes only and does not guarantee achievement of a specific result. The user is personally liable for incorrect use of repair equipment, tools or car parts, in particular, when this use poses the risk of injury. Coats & Gaiters strongly advises taking personal care and adhering to all safety rules when doing any repair or replacement. The use on inferior or low quality vehicle parts does not guarantee the proper level of road safety.

#aircompressor #sip #compressor

⚡Useful Tools. Some Used In This Video

⚡Coats and Gaiters is a participant of the Amazon Influencer Program.

I may earn a small commission with my affiliate links, though the prices paid are no higher but they do help me fund this channel.

⬇️Timecodes

00:00 Introduction

00:57 Opening up the Capacitor Box

02:24 Why do motors use capacitors?

04:08 Using a Fluke 77 to test the capacitors

04:52 Testing the Start capacitor

07:37 Testing the Run capacitor

09:06 A word of warning on replacing capacitors

10:23 Testing motor with drive belt removed

11:43 Creating an air leak

12:35 Check valve leaking continuously

13:41 Opening up the check valve

14:52 Photographs of parts

15:22 Still left puzzled !!!

17:14 Compressor seems to be working

17:52 Credits

🎁 Donations to help my Channel Grow 🎁

📹Some Of The Equipment Used To Create This Video:

1️⃣ Vegas 18 Pro Video Editing Software for the PC

⚡Other Social Media Links For Coats and Gaiters

Disclaimer:

This video only contains tips and my personal methods that could be helpful when carrying out home car repairs or replacing parts. Coats & Gaiters is not liable for any harm, injury or property damage incurred while carrying out such repairs or replacements, that are a result of incorrect use or misinterpretation of the provided information. This video is for informational purposes only and does not guarantee achievement of a specific result. The user is personally liable for incorrect use of repair equipment, tools or car parts, in particular, when this use poses the risk of injury. Coats & Gaiters strongly advises taking personal care and adhering to all safety rules when doing any repair or replacement. The use on inferior or low quality vehicle parts does not guarantee the proper level of road safety.

#aircompressor #sip #compressor

Комментарии

0:06:25

0:06:25

0:01:39

0:01:39

0:00:31

0:00:31

0:01:44

0:01:44

0:03:23

0:03:23

0:04:41

0:04:41

0:01:36

0:01:36

0:01:24

0:01:24

0:00:07

0:00:07

0:14:35

0:14:35

0:00:42

0:00:42

0:03:10

0:03:10

0:01:33

0:01:33

0:00:59

0:00:59

0:01:51

0:01:51

0:04:08

0:04:08

0:02:12

0:02:12

0:01:17

0:01:17

0:14:08

0:14:08

0:01:57

0:01:57

0:01:43

0:01:43

0:02:03

0:02:03

0:00:36

0:00:36

0:01:54

0:01:54