filmov

tv

Peltier Cascading - Does It Work??

Показать описание

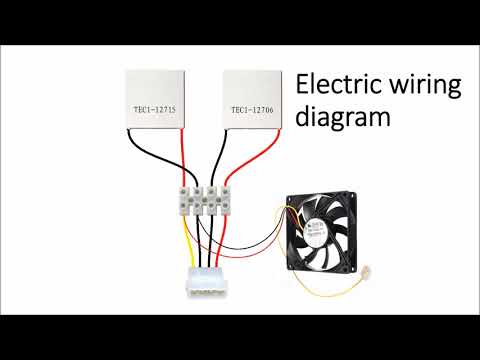

In this video, we will test whether or not cascading 2 TEC or peltier modules together increases cooling capacity and whether it is worth doing or not. Cascading is a concept where the hot side of one peltier is cooled by the cold side of another peltier to hopefully make the first peltier perform better. Confused? Watch the video and I'll explain.

Peltier Cascading - Does It Work??

Peltier War! - Cascading Vs Double Power

How efficient are cheap peltier elements? (peltier cascade test)

Peltier coolers, how do they work? #peltier #thermoelectric #cooler #electronics

Stacking 5 Peltier Modules, and Reached -90℃

Peltier effect, mini ac time lapse #shorts #diy #science

using a Peltier device to cool a CPU BELOW 0°! #shorts

Peltier water cooling circuit

Peltier Cascade Cooler/Freezer

Making Cooler/Generator with Thermoelectric Device

The best (cheap) Peltier module [test 2]

First test with alcohol three stages cascade

EXTREMELY LOW TEMPERATURES! - Using TECs

How to build a cloud chamber in 1 minute #science #physics #radioactive #Peltier #cloudchamber

Electronics: Can Peltier devices be cascaded? (7 Solutions!!)

Life Saving Hack With Peltier Modules

Is Liquid Nitrogen production with Peltier-Element possible? How cold can they get?

Stacking Cheap Peltier Modules - Lower than -40°C

stacked Peltier modules for very low temperatures less than -60°C

Peltier Cooler as Dehumidifier Grows Ice Crystals

Liquid Cooled Peltier (TEC) Refrigerator - Part 4

🎓 Understanding Peltiers ⚡️ TEC Stacking, Parallel. Episode4

Chinese Peltier Performance

-60C Peltier Cooler

Комментарии

0:06:20

0:06:20

0:03:31

0:03:31

0:01:00

0:01:00

0:14:49

0:14:49

0:00:06

0:00:06

0:01:01

0:01:01

0:00:26

0:00:26

0:07:08

0:07:08

0:14:37

0:14:37

0:10:16

0:10:16

0:01:18

0:01:18

0:14:41

0:14:41

0:00:58

0:00:58

0:05:36

0:05:36

0:08:13

0:08:13

0:04:04

0:04:04

0:03:10

0:03:10

0:02:24

0:02:24

0:08:51

0:08:51

0:06:33

0:06:33

0:17:51

0:17:51

0:00:13

0:00:13

0:03:43

0:03:43