filmov

tv

Use Arduino to Control a Large Stepper Motor! Part 1

Показать описание

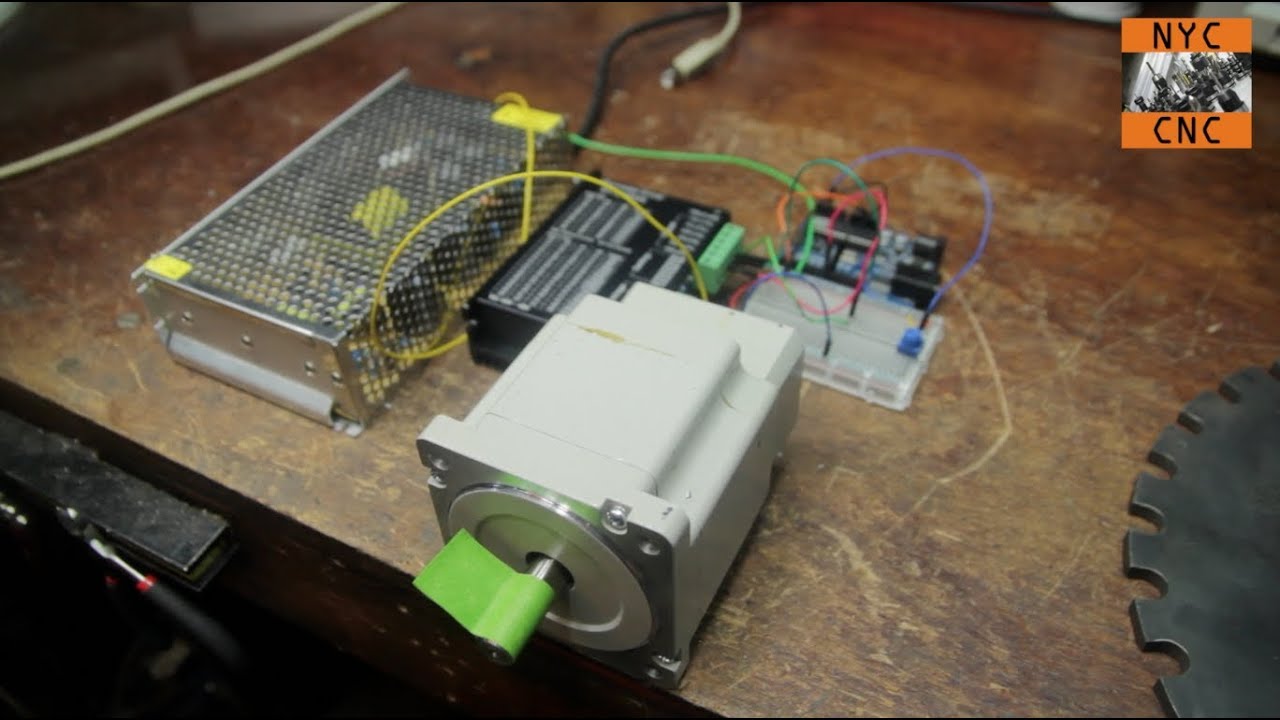

Video Tutorial on how to control large, Nema 34 Stepper motors with an Arduino, a 24V power supply and an ST-M5045 microstepping driver.

I'm no expert on this subject matter and am anticipating (hoping!) others may have comments with even better hardware or software tips and tricks - but in the meantime there doesn't seem to be much content on YouTube on driving large Steppers with Arduino's, and I've had quite a few email inquiries about it, so here it is!

In this video, we machine a 0.75" hole in a ~7LB, 15" 1/4 inch steel plate, then turn a bushing which will let us secured the plate to the stepper D-shaft.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Links for this video:

Arduino CNC Supplies:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Reach us / CNC Info:

Manufacturing Entrepreneurship Resources:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

I'm no expert on this subject matter and am anticipating (hoping!) others may have comments with even better hardware or software tips and tricks - but in the meantime there doesn't seem to be much content on YouTube on driving large Steppers with Arduino's, and I've had quite a few email inquiries about it, so here it is!

In this video, we machine a 0.75" hole in a ~7LB, 15" 1/4 inch steel plate, then turn a bushing which will let us secured the plate to the stepper D-shaft.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Links for this video:

Arduino CNC Supplies:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Reach us / CNC Info:

Manufacturing Entrepreneurship Resources:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

NEVER buy this JOYSTICK! #electronics #engineering #arduino

Gesture-Controlled Servo with Python and Arduino #electronics #arduinotraining

Control a DC Motor with Arduino (Lesson #16)

Control a Solenoid with an Arduino (Tutorial)

You can learn Arduino in 15 minutes.

Control AC Devices with Arduino SAFELY - Relays & Solid State Switches

ESP8266 + Arduino + database - Control Anything from Anywhere

Use Arduino to Control a Large Stepper Motor! Part 1

Control a Pump with Arduino (Lesson #15)

Arduino Tutorial: LED Sequential Control- Beginner Project

learn Arduino programming in 20 seconds!! (Arduino projects)

MOSFETs and Transistors with Arduino

Arduino MASTERCLASS | How to Use Control Structures PART 6

Control a Positional Servo Motor with an Arduino (Lesson #10)

How to use Arduino as TV Remote Controller with Infrared

Multiple Servo Motor Control #servo #arduino #esp32 #diy

Using IR Remote Controls with the Arduino

Arduino Tutorial 37: Understanding How to Control DC Motors in Projects

Arduino Controlled ESC (Easy+ No Potentiometer!)

When The Quiet Kid Does Your Homework 💀 #electronics #arduino #engineering

LED Control with LDR (Photoresistor) and Arduino

Control Stepper Motor with Arduino - Tutorial

Stepper Motors and Arduino - The Ultimate Guide

Control a Stepper Motor using an IR Remote and Arduino UNO - Tutorial

Комментарии

0:00:13

0:00:13

0:00:16

0:00:16

0:14:01

0:14:01

0:20:01

0:20:01

0:16:34

0:16:34

0:43:46

0:43:46

0:13:51

0:13:51

0:25:12

0:25:12

0:11:05

0:11:05

0:03:53

0:03:53

0:00:21

0:00:21

0:40:50

0:40:50

0:21:39

0:21:39

0:08:28

0:08:28

0:11:15

0:11:15

0:00:16

0:00:16

0:35:28

0:35:28

0:31:25

0:31:25

0:07:11

0:07:11

0:00:17

0:00:17

0:04:22

0:04:22

0:05:44

0:05:44

0:29:57

0:29:57

0:08:04

0:08:04