filmov

tv

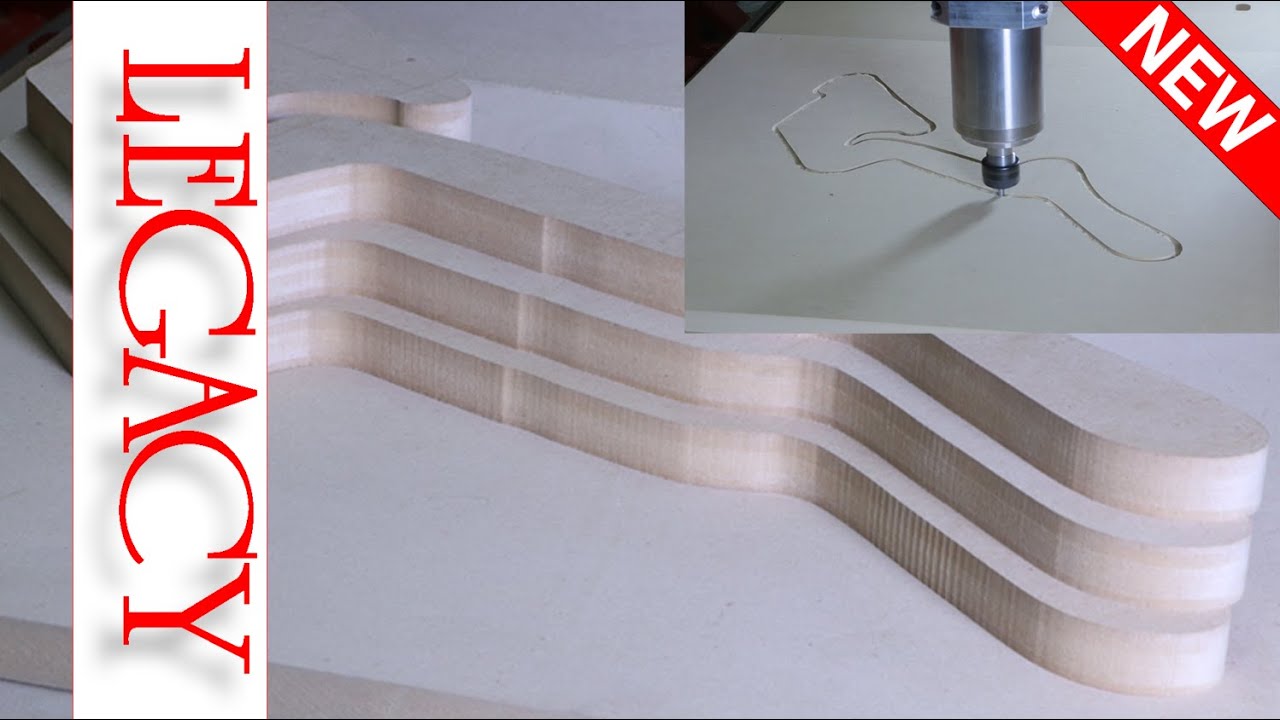

CNC Router 3x Faster Time Study - Maverick 3x5 Pro - Release Date Mar 1st - Legacy CNC Woodworking.

Показать описание

Legacy just announced the New Maverick 3x5 Pro Model. We claimed that the Pro has cutting speeds up to 3x faster than the original Maverick 3x5. That is 3x faster cutting speeds = 3x more parts = 3x more profit!

This is video proof.

This is the newest time-study on the Maverick 3x5 Pro!

Find more specs and details on the Maverick 3x5 Pro Here.

We are comparing apples to apples with this test. The only difference between the Maverick 3x5 and the Maverick 3x5 Pro is the Delta Controller. They both have the same:

Motors.

Drive system.

Spindle.

Frame

Router bits.

This test is a race between the Maverick 3x5 and the Maverick 3x5 Pro. A race where speed and "smooth cornering" cut-quality counts. We chose the tool path for this race: Nürburgring Grand Prix Race Track's profile located in Nürburg, Rhineland-Palatinate, Germany.

----- Test 1 -----

Parameters:

Machine: Maverick 3x5, Maverick 3x5 Pro

Cutter: .25" Compression Cutter

Material: .75" MDF

Pattern: Profile of Nürburgring Grand Prix Race Track

Inspected: Speed, Cut Quality

Results:

Maverick 3x5

Feed Rate: 360 IPM

Pass Depth: .4"

Run Time: 50 seconds

Quality Of Cut: Visible Transition Marks

Maverick 3x5 Pro

Feed Rate: 360 IPM

Pass Depth: .4"

Run Time: 22 seconds

Quality Of Cut: Smooth Edges, No Visible Marks

Significant Differences:

Quality of cut. While the maverick 3x5 motors, drive system, and spindle were all up to the task, the Mach3 controller could not hold the speed and cut-quality as well as the Delta controller.

Quality is King.

As Craftsmen, we are defined by the quality of our work. We were not satisfied with the quality of the cut that the Maverick 3x5 produced. We lowered the speed of the Maverick 3x5 down and performed another test. We continued testing until we had both machines producing excellent smooth race tracks. Here are the results:

----- Test 2 -----

Parameters:

Machine: Maverick 3x5

Cutter: .25" Compression Cutter

Material: .75" MDF

Pattern: Profile of Nürburgring Grand Prix Race Track

Inspected: Speed, Cut Quality

Feed Rate: 120 IPM, 100 IPM, 80 IPM

Pass Depth: .26"

Significant Differences:

The 80 IPM test cut had the most comparable finish to the Maverick 3x5 Pro test cut. The difference is that the Maverick 3x5 Pro performed the same cut at 360 IPM.

Compared To Maverick 3x5 Pro:

Maverick 3x5

Feed Rate: 80 IPM

Pass Depth: .26"

Run Time: 131 Seconds

Quality Of Cut: Smooth Edges, No Visible Marks

Maverick 3x5 Pro

Feed Rate: 360 IPM

Pass Depth: .4"

Run Time: 22 Seconds

Quality Of Cut: Smooth Edges, No Visible Marks

Significant Differences:

Feed Rate: 80 IPM - 360 IPM (4x faster - 400% increase)

Pass Depth: .26" - .4" (1.5x deeper - 50% increase)

Run Time: 131 sec - 22 sec (approaching x6 faster - 595% increase)

The Difference Is Solely The Delta Controller:

The hardware of the Delta Controller has a higher rate of communication with the motor drivers. The software has better algorithms to handle multi-axis travel. These two factors make all the difference in this test.

This improvement is fascinating because the Maverick 3x5 Pro can produce the highest quality parts faster, in this case, 6x more quickly. That means kitchen remodels, signs & gifts for friends, unique niche products, and more things off the to-do list, all happening faster!

This test is just one situation. This test doesn't mean that every cutting process will have the same results. The Maverick 3x5 Pro produced these results because it cuts deeper and moves faster without sacrificing a smooth cut, especially when performing multi-axis movements. There will be situations where plunging deeper and moving faster do not apply. It will affect at least 80% of the cutting processes that the woodworkers on the legacy staff use on a regular basis.

The Maverick 3x5 Pro is not for everyone. Some people look at the price difference, and the original Maverick 3x5 has everything that they need. It has a 3 axis table, turning center, and joinery center, just like the Pro version. It has the same cut quality that the Maverick 3x5 Pro can achieve, just at a slower rate.

Thanks, there is more to the Maverick 3x5 Pro than just speed. We built the New Controller with many new features as well. We plan to release a new video on those benefits next week so stay tuned.

or

Call 1-801-609-2805

#cncrouter

#cnclathe

#cncturning

#cncwoodworking

#legacycnc

This is video proof.

This is the newest time-study on the Maverick 3x5 Pro!

Find more specs and details on the Maverick 3x5 Pro Here.

We are comparing apples to apples with this test. The only difference between the Maverick 3x5 and the Maverick 3x5 Pro is the Delta Controller. They both have the same:

Motors.

Drive system.

Spindle.

Frame

Router bits.

This test is a race between the Maverick 3x5 and the Maverick 3x5 Pro. A race where speed and "smooth cornering" cut-quality counts. We chose the tool path for this race: Nürburgring Grand Prix Race Track's profile located in Nürburg, Rhineland-Palatinate, Germany.

----- Test 1 -----

Parameters:

Machine: Maverick 3x5, Maverick 3x5 Pro

Cutter: .25" Compression Cutter

Material: .75" MDF

Pattern: Profile of Nürburgring Grand Prix Race Track

Inspected: Speed, Cut Quality

Results:

Maverick 3x5

Feed Rate: 360 IPM

Pass Depth: .4"

Run Time: 50 seconds

Quality Of Cut: Visible Transition Marks

Maverick 3x5 Pro

Feed Rate: 360 IPM

Pass Depth: .4"

Run Time: 22 seconds

Quality Of Cut: Smooth Edges, No Visible Marks

Significant Differences:

Quality of cut. While the maverick 3x5 motors, drive system, and spindle were all up to the task, the Mach3 controller could not hold the speed and cut-quality as well as the Delta controller.

Quality is King.

As Craftsmen, we are defined by the quality of our work. We were not satisfied with the quality of the cut that the Maverick 3x5 produced. We lowered the speed of the Maverick 3x5 down and performed another test. We continued testing until we had both machines producing excellent smooth race tracks. Here are the results:

----- Test 2 -----

Parameters:

Machine: Maverick 3x5

Cutter: .25" Compression Cutter

Material: .75" MDF

Pattern: Profile of Nürburgring Grand Prix Race Track

Inspected: Speed, Cut Quality

Feed Rate: 120 IPM, 100 IPM, 80 IPM

Pass Depth: .26"

Significant Differences:

The 80 IPM test cut had the most comparable finish to the Maverick 3x5 Pro test cut. The difference is that the Maverick 3x5 Pro performed the same cut at 360 IPM.

Compared To Maverick 3x5 Pro:

Maverick 3x5

Feed Rate: 80 IPM

Pass Depth: .26"

Run Time: 131 Seconds

Quality Of Cut: Smooth Edges, No Visible Marks

Maverick 3x5 Pro

Feed Rate: 360 IPM

Pass Depth: .4"

Run Time: 22 Seconds

Quality Of Cut: Smooth Edges, No Visible Marks

Significant Differences:

Feed Rate: 80 IPM - 360 IPM (4x faster - 400% increase)

Pass Depth: .26" - .4" (1.5x deeper - 50% increase)

Run Time: 131 sec - 22 sec (approaching x6 faster - 595% increase)

The Difference Is Solely The Delta Controller:

The hardware of the Delta Controller has a higher rate of communication with the motor drivers. The software has better algorithms to handle multi-axis travel. These two factors make all the difference in this test.

This improvement is fascinating because the Maverick 3x5 Pro can produce the highest quality parts faster, in this case, 6x more quickly. That means kitchen remodels, signs & gifts for friends, unique niche products, and more things off the to-do list, all happening faster!

This test is just one situation. This test doesn't mean that every cutting process will have the same results. The Maverick 3x5 Pro produced these results because it cuts deeper and moves faster without sacrificing a smooth cut, especially when performing multi-axis movements. There will be situations where plunging deeper and moving faster do not apply. It will affect at least 80% of the cutting processes that the woodworkers on the legacy staff use on a regular basis.

The Maverick 3x5 Pro is not for everyone. Some people look at the price difference, and the original Maverick 3x5 has everything that they need. It has a 3 axis table, turning center, and joinery center, just like the Pro version. It has the same cut quality that the Maverick 3x5 Pro can achieve, just at a slower rate.

Thanks, there is more to the Maverick 3x5 Pro than just speed. We built the New Controller with many new features as well. We plan to release a new video on those benefits next week so stay tuned.

or

Call 1-801-609-2805

#cncrouter

#cnclathe

#cncturning

#cncwoodworking

#legacycnc

Комментарии

0:04:37

0:04:37

0:06:43

0:06:43

0:00:15

0:00:15

0:00:24

0:00:24

0:02:04

0:02:04

0:00:13

0:00:13

0:10:29

0:10:29

0:00:11

0:00:11

0:00:20

0:00:20

0:00:10

0:00:10

0:15:08

0:15:08

0:03:58

0:03:58

0:00:38

0:00:38

0:01:00

0:01:00

0:00:11

0:00:11

0:04:19

0:04:19

0:08:21

0:08:21

0:00:11

0:00:11

0:05:24

0:05:24

0:00:18

0:00:18

1:02:47

1:02:47

0:00:52

0:00:52

0:15:03

0:15:03

0:10:45

0:10:45