filmov

tv

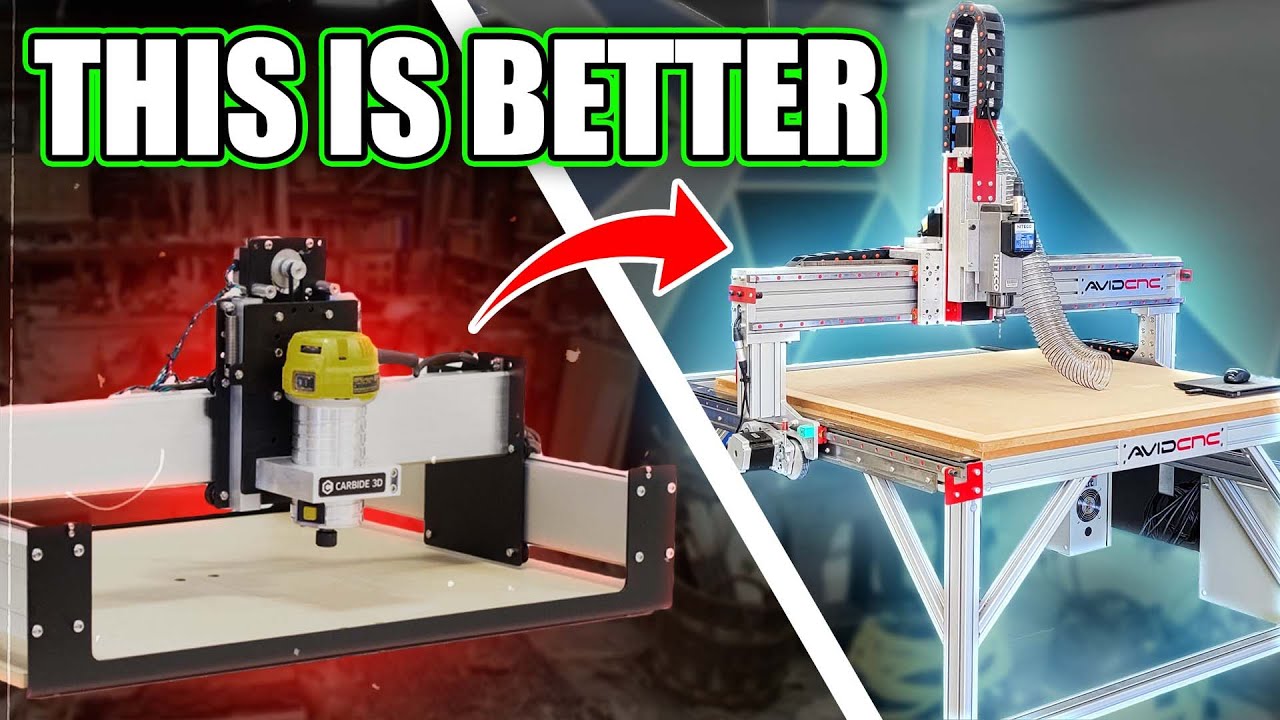

Buying the WRONG CNC Router will cost you THOUSANDS.

Показать описание

Buying a CNC is a big decision. This video will make that decision easier and give you a lot to consider before you invest.

CNC's In This Video

Support Andy Bird Builds Channel

Tools To Help You Make Money With Your CNC

Interested in getting started in CNC, but don't know where to start?

A great way to support Andy Bird Builds is to purchase through affiliate links, you get what you need and I may get a kickback!

#andybirdbuilds #cncrouter #cncwoodworking

CNC's In This Video

Support Andy Bird Builds Channel

Tools To Help You Make Money With Your CNC

Interested in getting started in CNC, but don't know where to start?

A great way to support Andy Bird Builds is to purchase through affiliate links, you get what you need and I may get a kickback!

#andybirdbuilds #cncrouter #cncwoodworking

Buying the WRONG CNC Router will cost you THOUSANDS.

Watch BEFORE You Buy a CNC Router in 2024

Don't Buy A CNC Before Watching This Video

Watch This BEFORE Buying a CNC Machine (10 regrets to avoid)

The Hidden Costs of CNC's!

Watch This Before You Buy A CNC Router In 2023

Don’t Buy Old CNC Machines | CNC Repairman

What CNC should I buy

WATCH THIS BEFORE BUYING ANY CNC MACHINE

Buying CNC Machines: Advice & Mistakes to avoid!

CNC Build Ep 1: What is the Best CNC For You? Why I bought Avid CNC vs Phantom, Laguna, Shop Sabre

Don't Buy the Wrong Router #woodworking

Avoid CNC Mistakes: Essential Tips for First-Time Buyers

Watch This Before You Buy A Desktop CNC Router

Don't Buy a CNC Machine

The Haters Guide to CNC Machines | Watch Before You Buy!

Industrial CNC Routers Quick Cuts - 5 Reasons To Buy A CNC Router

#cnc #manufacturing #technology #engineering #factory #turning #crash

5 Tools You NEED To Purchase After Buying A CNC

CNC Basics - What You Need To Get Started

The Ultimate CNC Router Review Buyers Guide, Best CNC Routers

Does your CNC router use rubber belts? Bad idea. Ask before buying-- CNC Tech by CNC Factory

Buyers Guide to CNC Milling: From Purchase to Machining

Buying your first CNC Machine and what you should ABSOLUTLY KNOW before you buy yours!

Комментарии

0:15:01

0:15:01

0:08:55

0:08:55

0:10:15

0:10:15

0:21:21

0:21:21

0:11:48

0:11:48

0:16:34

0:16:34

0:04:56

0:04:56

0:05:13

0:05:13

0:12:31

0:12:31

0:35:38

0:35:38

0:19:12

0:19:12

0:00:38

0:00:38

0:16:25

0:16:25

0:08:49

0:08:49

0:00:35

0:00:35

0:26:38

0:26:38

0:03:45

0:03:45

0:00:12

0:00:12

0:05:46

0:05:46

0:09:18

0:09:18

1:47:57

1:47:57

0:04:46

0:04:46

0:09:38

0:09:38

0:15:35

0:15:35