filmov

tv

Motor Starters, Soft Starters, and VFD's

Показать описание

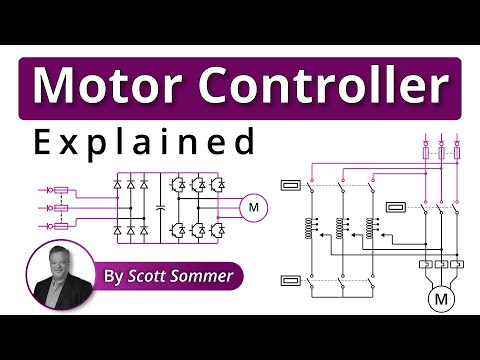

A starter is a device that allows us to safely start and stop a motor (primarily used in industrial applications). It is basically a switching device which can allow us to operate a motor from a remote location. They also give use the ability to monitor the state of the motor (run status).

They consist of several parts including:

- Contactor

- Overload

- Circuit protection (not required, but common)

Typically used in areas where basic motor control is needed. Where torque on the motor is not a concern and where there is no speed control needed.

Advantages

- Lower cost

- Allows for remote operation

- Allows us to monitor motor state (w/ use of Aux. Contacts)

- Safe

- Efficient

Disadvantages

- High In-rush current (6-8 more current then the FLA (full load amps) of the motor). This can cause fuse to burn up and breakers to trip if the inrush is too high.

- Will allow a full torque start of the motor (this means that when power is applied to the motor, full current is applied to the motor instantly. This causes the motor to ramp up to full speed very quickly. This creates a lot of torque; this high amount of torque can cause the motor to wear and degrade more quickly.

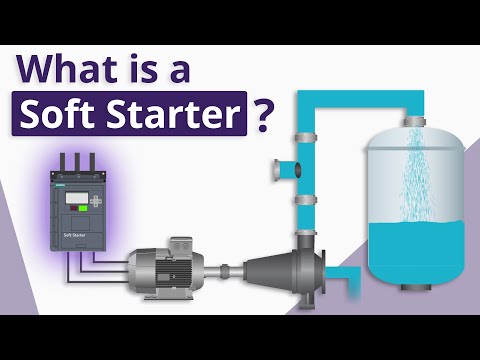

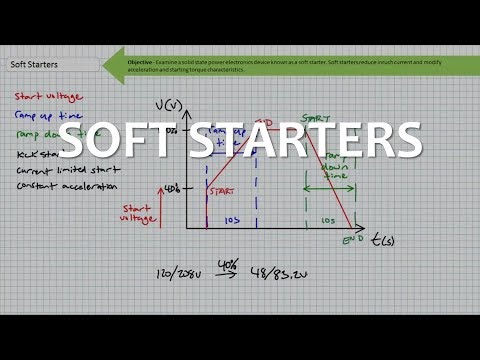

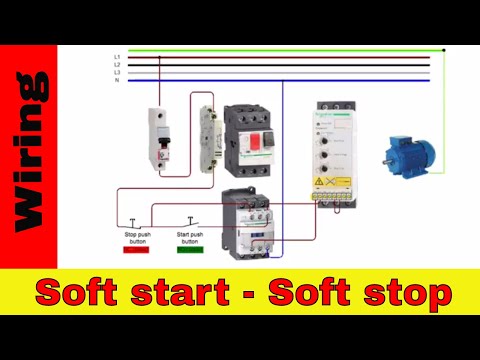

Provide all the same functions as a traditional starter. In addition, a soft starter is a device protects AC electrical motors from being damaged by sudden spikes of power. It does this by limiting the inrush current that can be cause by AC motors upon startup. They allow us to gently ramp up the motor to full speed. They are most commonly used upon startup only, however some models allow a ramp down period during shutdown as well. By slowing increasing the voltage upon startup, we are able to produce a gradual increase in motor speed.

Common Applications of Soft Starters

- Where torque and wear and tear on the motor is a concern

- When we need to reduce the inrush current that is created upon motor startup. (Saves money, saves motor)

- In pumping systems where it is necessary to reduce the pressure surge by a fast startup of a motor or pump.

Advantages

- Less expensive than a VFD when control is needed for startup only

- Smaller than other system, so space is not as much of a concern in comparison to VFD’s

- Allow for reduced inrush current

- Saves unwanted torque to the motor upon startup, prolonging the life of the motor.

Disadvantages

- More expensive than a normal motor starter

- Don’t allow for full speed control

VFD’s can provide all of the same functions as both starters and soft starts with some additional functionality. A VFD is a motor control device that allows us to both protect the motor as well as give us almost full control over the speed of the motor (AC motors). A VFD gives us the ability to slowly ramp of and down the speed during the start and stop of the motor, but it also allows for full speed control during the entire run cycle of the motor. This allows for more efficient use of the motor allowing use to save money and reduces the stress applied to the motor due to running at speed 100% of the time.

Common applications for VFD use:

- Where full speed control is required on the motor

- When energy savings is important

- Example: based of the laws the govern how much power is needed to run at certain speeds, if you can run a motor at 70% speed, you would only need about 35% of the power needed to run the motor at full speed. That offers a huge savings in electrical costs.

- Where more custom control and monitoring is required

Advantages

- Full speed control (Start, Stop, and in-between)

- Typically, more custom control and monitoring

- Energy savings due to more efficient motor usage

- Less wear on tear on the motors they are connected to

Disadvantages

- They are the most expensive options for motor control

- They often are much larger than other options and require much more space

- They can generate large amounts of heat that may require fan units or AC units

Motor & Motor Control:

PLCs & IO:

Relays & Timers:

Panel Hardware:

Tools & Supplies:

Комментарии

0:08:33

0:08:33

0:01:31

0:01:31

0:07:30

0:07:30

0:07:57

0:07:57

0:02:22

0:02:22

0:00:25

0:00:25

0:07:30

0:07:30

0:06:29

0:06:29

0:01:01

0:01:01

0:06:42

0:06:42

0:08:30

0:08:30

0:04:28

0:04:28

0:07:58

0:07:58

0:04:02

0:04:02

0:22:42

0:22:42

0:11:08

0:11:08

0:04:44

0:04:44

0:09:27

0:09:27

0:01:50

0:01:50

0:02:42

0:02:42

0:05:43

0:05:43

0:00:37

0:00:37

0:04:13

0:04:13

0:01:34

0:01:34