filmov

tv

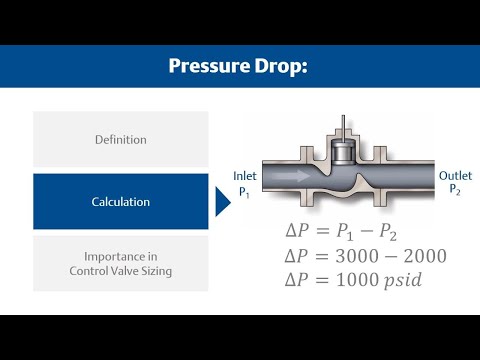

Control Valve Sizing Basics: What is Pressure Drop?

Показать описание

Learn more about pressure drop in control valves and how it's used in the control valve sizing equation.

Key takeaways:

- Pressure drop definition

- Pressure drop calculation

- Importance of pressure drop data in the control valve sizing equation and why it is critical for proper valve selection

Additional Resources:

Thanks for watching! Please like, share, and comment on our video and make sure to subscribe to the Fisher Valve & Instruments channel.

Key takeaways:

- Pressure drop definition

- Pressure drop calculation

- Importance of pressure drop data in the control valve sizing equation and why it is critical for proper valve selection

Additional Resources:

Thanks for watching! Please like, share, and comment on our video and make sure to subscribe to the Fisher Valve & Instruments channel.

Control Valve Sizing Basics: What is Pressure Drop?

Control Valve Sizing Made Simple | 3 Golden Rules

Control Valve Sizing Calculation Explained | Valve Flow Coefficient(Cv)

Control Valve Cv Calculation for Liquids | Simple Science

Control Valve Characteristics Selection | MOST SIMPLE EXPLANATION

Control Valve Sizing Basics@ChemicalMahi

Control Valve Basics

Why Shut Off Pressure is required for Control Valve Sizing | Control Valve Sizing | Instrumentation

Engineering Design Instrumentation Construction

How to Size a Control Valve for Liquid Flow

How to Size a Control Valve for Compressible Fluid

Valve Flow Coefficient (Valve Cv) Explained [How to Determine What Valve Size to Use]

Control Valve Selection (Most LOGICAL Explanation)

Control Valve Flow Coefficient Cv Basic Concept

Control Valve Sizing and Selection - Quick and Easy || Learning Engineering Solutions ||

How to Size a Control Valve for Gas Flow ? - Fisher Valve Sizing Software Tutorial

Control Valve Selection and Sizing | Building Management System Training | BMS Training 2021

Control Valve Sizing | Basics Of Control Valve | Types of Valve | Actuators | ATO | ATC | Part 1

Liquid Control Valve sizing calculation

Calculate of Control Valve Sizing with Software

What is CV in Control Valve | MOST Simple Explanation

Control Valve Material Selection

Webinar: Steam Valve Sizing and Selection

Control Valve Sizing | Aspen HYSYS

Комментарии

0:03:18

0:03:18

0:09:44

0:09:44

0:04:06

0:04:06

0:03:26

0:03:26

0:04:24

0:04:24

0:08:50

0:08:50

0:32:50

0:32:50

0:06:54

0:06:54

0:51:06

0:51:06

0:06:22

0:06:22

0:05:21

0:05:21

0:02:17

0:02:17

0:10:41

0:10:41

0:06:21

0:06:21

0:15:05

0:15:05

0:04:31

0:04:31

0:15:19

0:15:19

0:42:11

0:42:11

0:08:47

0:08:47

0:06:29

0:06:29

0:04:49

0:04:49

0:08:40

0:08:40

0:39:16

0:39:16

0:04:43

0:04:43