filmov

tv

Reaching Breaking Point: Materials, Stresses, & Toughness: Crash Course Engineering #18

Показать описание

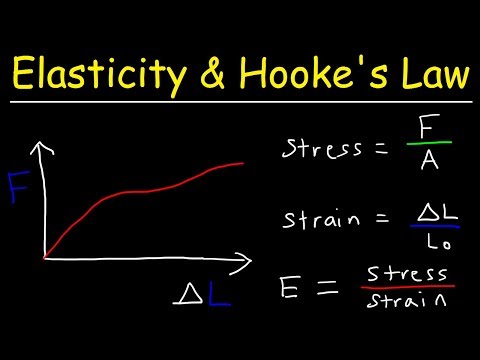

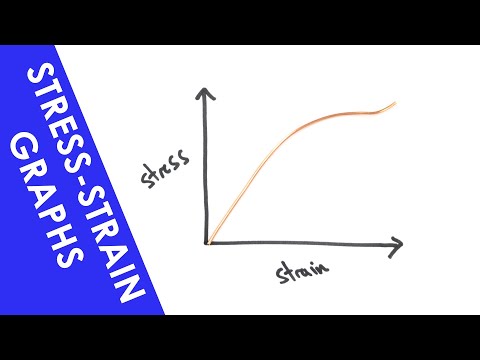

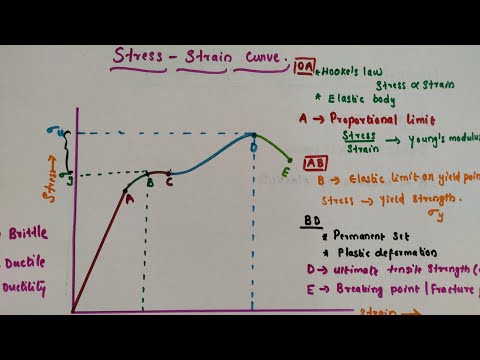

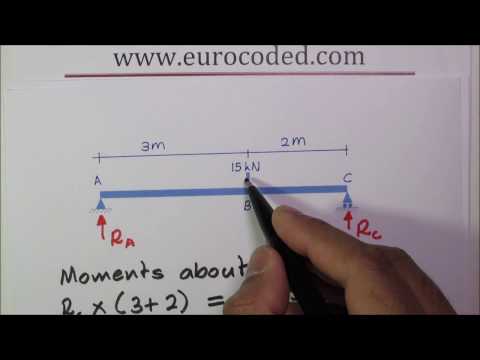

Today we’re going to start thinking about materials that are used in engineering. We’ll look at mechanical properties of materials, stress-strain diagrams, elasticity and toughness, and describe other material properties like hardness, creep strength, and fatigue strength.

***

RESOURCES:

***

Thanks to the following Patrons for their generous monthly contributions that help keep Crash Course free for everyone forever:

Mark Brouwer, Trevin Beattie, Satya Ridhima Parvathaneni, Erika & Alexa Saur, Glenn Elliott, Justin Zingsheim, Jessica Wode, Eric Prestemon, Kathrin Benoit, Tom Trval, Jason Saslow, Nathan Taylor, Brian Thomas Gossett, Khaled El Shalakany, Indika Siriwardena, SR Foxley, Sam Ferguson, Yasenia Cruz, Eric Koslow, Caleb Weeks, Tim Curwick, D.A. Noe, Shawn Arnold, Ruth Perez, Malcolm Callis, Advait Shinde, William McGraw, Andrei Krishkevich, Rachel Bright, Mayumi Maeda, Kathy & Tim Philip, Eric Kitchen, Ian Dundore, Chris Peters

--

Want to find Crash Course elsewhere on the internet?

***

RESOURCES:

***

Thanks to the following Patrons for their generous monthly contributions that help keep Crash Course free for everyone forever:

Mark Brouwer, Trevin Beattie, Satya Ridhima Parvathaneni, Erika & Alexa Saur, Glenn Elliott, Justin Zingsheim, Jessica Wode, Eric Prestemon, Kathrin Benoit, Tom Trval, Jason Saslow, Nathan Taylor, Brian Thomas Gossett, Khaled El Shalakany, Indika Siriwardena, SR Foxley, Sam Ferguson, Yasenia Cruz, Eric Koslow, Caleb Weeks, Tim Curwick, D.A. Noe, Shawn Arnold, Ruth Perez, Malcolm Callis, Advait Shinde, William McGraw, Andrei Krishkevich, Rachel Bright, Mayumi Maeda, Kathy & Tim Philip, Eric Kitchen, Ian Dundore, Chris Peters

--

Want to find Crash Course elsewhere on the internet?

Комментарии

0:11:24

0:11:24

0:07:19

0:07:19

0:04:22

0:04:22

0:06:49

0:06:49

0:19:01

0:19:01

0:00:12

0:00:12

0:02:15

0:02:15

0:00:54

0:00:54

4:01:19

4:01:19

0:08:53

0:08:53

0:16:07

0:16:07

0:10:08

0:10:08

0:06:10

0:06:10

0:04:37

0:04:37

0:41:10

0:41:10

0:02:26

0:02:26

0:21:48

0:21:48

0:00:46

0:00:46

0:08:12

0:08:12

0:20:49

0:20:49

0:09:05

0:09:05

0:04:27

0:04:27

0:17:33

0:17:33

0:08:35

0:08:35