filmov

tv

ETP PLANT FLOW DIAGRAM # DASA TECHSTUDY# please subscribe and share and like.

Показать описание

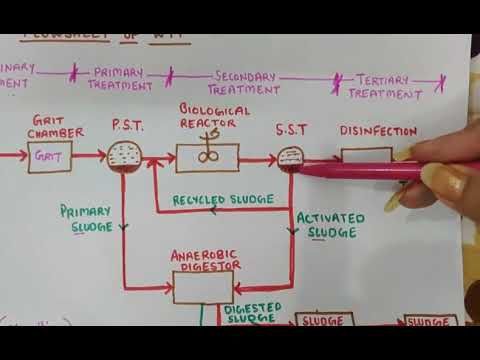

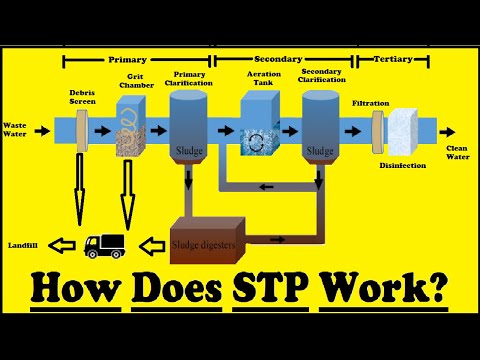

ETP PLANT: ETP is therefore designed to remove the physical, chemical and biological materials present in the effluent. Depending on the level of treatment the wastewater requires, an ETP is divided into four different levels each designed to remove a certain type of material in the effluent.

WHY NEED ETP IN INDUSTRY :

Sludge: Solid part separated from waste water by ETP. To clean industry effluent and recycle it for further use. To reduce the usage of fresh/potable water in Industries. To cut expenditure on water procurement.

HOW REMOVE SLUDGE :

There are various options for treating sludge including stabilization, thickening, dewatering, drying, and incineration. The costs for treating sludge and removing sludge from wastewater are roughly the same. Typically a polymer chemical is used for the volume reduction process known as dewatering.

MY CHANNEL NAME

DASA TECHSTUDY

You need any technical videos please send notice through feedback.

Thank you

WHY NEED ETP IN INDUSTRY :

Sludge: Solid part separated from waste water by ETP. To clean industry effluent and recycle it for further use. To reduce the usage of fresh/potable water in Industries. To cut expenditure on water procurement.

HOW REMOVE SLUDGE :

There are various options for treating sludge including stabilization, thickening, dewatering, drying, and incineration. The costs for treating sludge and removing sludge from wastewater are roughly the same. Typically a polymer chemical is used for the volume reduction process known as dewatering.

MY CHANNEL NAME

DASA TECHSTUDY

You need any technical videos please send notice through feedback.

Thank you

0:00:41

0:00:41

0:00:54

0:00:54

0:03:31

0:03:31

0:04:18

0:04:18

0:04:28

0:04:28

0:10:03

0:10:03

0:03:29

0:03:29

0:04:14

0:04:14

0:00:52

0:00:52

0:01:46

0:01:46

0:12:54

0:12:54

0:08:01

0:08:01

0:00:50

0:00:50

0:10:07

0:10:07

0:11:12

0:11:12

0:00:10

0:00:10

0:00:57

0:00:57

0:08:07

0:08:07

0:00:28

0:00:28

0:20:04

0:20:04

0:01:08

0:01:08

0:12:53

0:12:53

0:00:15

0:00:15

0:01:51

0:01:51