filmov

tv

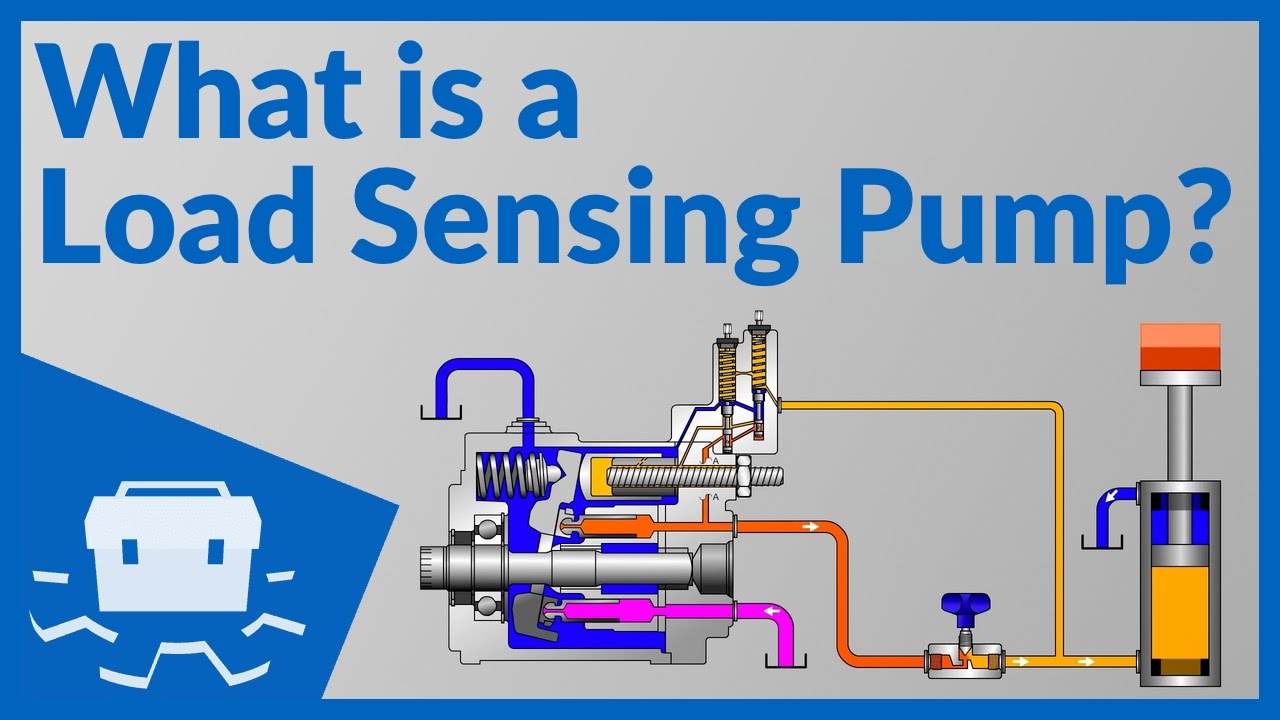

What is a Load Sensing Pump?

Показать описание

Load Sensing Pumps are one of the most interesting subjects in industrial hydraulics. With just a few tweaks to a typical pressure compensator, you get a surprising improvement in efficiency and responsiveness. Today, we begin to explore how load sense works; in future videos, we'll go a whole lot deeper.

Follow us for more great videos and learning content on your preferred social network.

Follow us for more great videos and learning content on your preferred social network.

What is a Load Sensing Pump?

Unsere neuen Diesel- und Treibgasstapler: Load-Sensing-System

What is a load cell and how does it work? Explained

Load Sensing Accuracy

Load Sense Live Schematic

Load sensing control

Instructiefilm Load Sensing Techniek

Einschulungsvideo: Hydrauliksysteme | GÖWEIL

Samsung Bespoke AI WW11BB704DGW - Colours 40° with Intensive - Full Cycle

e-Load-Sensing - the next generation of hydraulic systems

A load sensing system

Clip 6 - Load Sensing edit | AEA

Pressure Compensated Flow Control Valves in a Load Sense System

Automatic load sensing on your washing machine

How To Read Load Sense Pump Symbols

How To Work With A Hydraulic Load Sense System - AskAPT 9

Dynamics of a Load Sense System Adjustment

REXROTH LOAD SENSING DRF DFR PUMP CONTROL EXPLAINED PART 2

load sensing

2-Wege Druckwaagen-Funktion beim Anstieg des Lastdruckes

How to adjust the hydraulic load sensing pump : training course

Fonctionnement pompe hydraulique avec régulation Load Sensing (LS)

Pressure Compensated Load Sense hydraulic system explained

Load Sense Bleed to Standby

Комментарии

0:03:51

0:03:51

0:00:33

0:00:33

0:01:21

0:01:21

0:04:17

0:04:17

0:06:04

0:06:04

0:17:42

0:17:42

0:08:25

0:08:25

0:09:18

0:09:18

1:09:14

1:09:14

0:03:09

0:03:09

0:02:36

0:02:36

0:00:41

0:00:41

0:03:55

0:03:55

0:02:08

0:02:08

0:06:03

0:06:03

0:04:44

0:04:44

0:06:00

0:06:00

0:11:32

0:11:32

0:19:25

0:19:25

0:00:30

0:00:30

0:05:20

0:05:20

0:15:42

0:15:42

0:23:58

0:23:58

0:03:15

0:03:15