filmov

tv

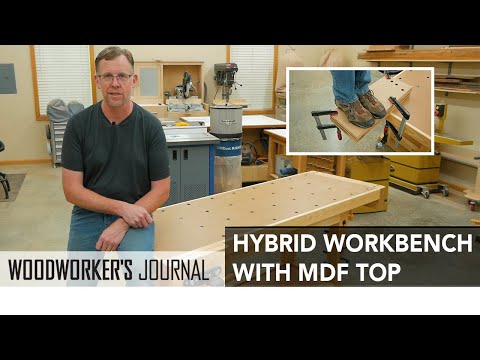

Why Use an MDF Workbench Top?

Показать описание

Chris Marshall discusses his hybrid workbench and some of the features that he's included. He speaks in-depth about the MDF workbench top, why he included it and what benefits having an MDF worksurface could bring to your workshop.

Subscribe to this channel for new weekly video woodworking lessons, tips and tricks:

Get more FREE project plans, expert tips and tool updates in our weekly email newsletter. Subscribe here:

Visit our website for the best woodworking projects and lessons:

Subscribe to this channel for new weekly video woodworking lessons, tips and tricks:

Get more FREE project plans, expert tips and tool updates in our weekly email newsletter. Subscribe here:

Visit our website for the best woodworking projects and lessons:

Why Use an MDF Workbench Top?

Why an MDF Workbench Top Is Better Than Plywood, Plywood vs 2x4 Pine, or Maple Strips

How to Finish MDF Workbench — How to Woodworking

What Are The Best MDF Workbench Top Alternatives: What Would I Use?

New Workshop MDF Work Surfaces with T-Track // Sealing MDF with Shellac

Don't Make These 5 Mistakes When Building Your Workbench!

The PERFECT small shop WORKBENCH

Watch This Before Building Your Workbench

Ultimate DIY Workbench: Unlocking the Secrets of Plywood and MDF

Danish Oil: The Key To A Perfect Mdf Workbench Worktop

Plywood or MDF for MFT Workbench Builds? JP's Vlog #4

Can the wrong finish ruin a workbench?

You're doing it wrong - MDF Workbench / Benchtop finish - Part 1 - Oil or water-based?

Four Workbench Building Mistakes (that we all make).

The Cosman Workbench - Cheap, Easy, and BEST WORKBENCH EVER

How to laminate MDF, OSB or Plywood for a workbench top!

My Workbench Gets Upgraded!

Best tip for when you design your workbench #shorts

why I chose to have a melamine workbench top

It's Time To Upgrade Your Workbench! (With Build Plans!)

How to Choose a Woodworking Workbench

Holdfast on MDF workbench

Building my ultimate workbench. Episode 1

Make the best out of your MFT-style workbench! All Bench dogs accessories!

Комментарии

0:06:51

0:06:51

0:13:09

0:13:09

0:02:59

0:02:59

0:09:41

0:09:41

0:11:56

0:11:56

0:11:39

0:11:39

0:21:39

0:21:39

0:17:23

0:17:23

0:16:40

0:16:40

0:11:35

0:11:35

0:12:48

0:12:48

0:02:47

0:02:47

0:19:51

0:19:51

0:21:18

0:21:18

0:13:33

0:13:33

0:12:27

0:12:27

0:11:14

0:11:14

0:00:58

0:00:58

0:00:47

0:00:47

0:15:07

0:15:07

0:19:05

0:19:05

0:01:10

0:01:10

0:18:03

0:18:03

0:13:33

0:13:33