filmov

tv

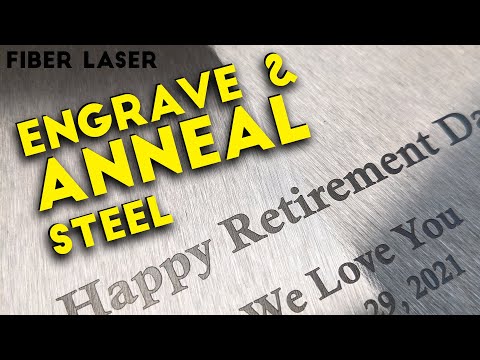

How to Engrave and ANNEAL Any STEEL with a Fiber | Fiber Laser Tutorials

Показать описание

In this fiber laser tutorial I'll teach you how to engrave and anneal any steel with Ezcad! In this video we cover the Laser Everything standard for steel engraving. These are my all time favorite settings for steel regardless of context or application and it's one of my most used settings combinations in the entire shop. I'm excited to share these fiber laser parameters with you and hope you can use them to better your business! Thanks so much for watching - we'll see ya in the next episode!

The channel, staff, communities, web services... everything. It's all here thanks to the LMA.

❤️ We're probably earning money when you buy stuff we link. ❤️

✨As Amazon Associates we earn from qualifying purchases.✨

You're going to love this content too!

► NEW MakerREMIX Channel! @MakerREMIX

We have SO MANY Laser Resources:

0:00 - Intro - Overview

1:17 - Setup and Alignment

3:45 - Steel General Settings

4:58 - Running Steel General

5:47 - Steel Anneal Settings

6:48 - Running Steel Anneal

7:14 - Anneal vs Non-Anneal

8:45 - Cleaning and Finishing

9:51 - Final Look

10:15 - Outro - Supporting the Channel

Listen up! Laser engraving machines are inherently dangerous. The content this channel is for educational purposes only. Laser Everything LLC can not be held liable for any harm caused to any individual or personal property related to settings, activities, procedures, techniques, or practices described in whole or part on this YouTube channel. By watching this video you agree that you alone are solely responsible for your own safety and property as it pertains to this content. Do your own research before purchasing machines, materials or accessories. LE is viewer supported and probably earns commission when you buy stuff we link.

The channel, staff, communities, web services... everything. It's all here thanks to the LMA.

❤️ We're probably earning money when you buy stuff we link. ❤️

✨As Amazon Associates we earn from qualifying purchases.✨

You're going to love this content too!

► NEW MakerREMIX Channel! @MakerREMIX

We have SO MANY Laser Resources:

0:00 - Intro - Overview

1:17 - Setup and Alignment

3:45 - Steel General Settings

4:58 - Running Steel General

5:47 - Steel Anneal Settings

6:48 - Running Steel Anneal

7:14 - Anneal vs Non-Anneal

8:45 - Cleaning and Finishing

9:51 - Final Look

10:15 - Outro - Supporting the Channel

Listen up! Laser engraving machines are inherently dangerous. The content this channel is for educational purposes only. Laser Everything LLC can not be held liable for any harm caused to any individual or personal property related to settings, activities, procedures, techniques, or practices described in whole or part on this YouTube channel. By watching this video you agree that you alone are solely responsible for your own safety and property as it pertains to this content. Do your own research before purchasing machines, materials or accessories. LE is viewer supported and probably earns commission when you buy stuff we link.

Комментарии

0:12:14

0:12:14

0:00:42

0:00:42

0:00:56

0:00:56

0:04:01

0:04:01

0:00:28

0:00:28

0:07:08

0:07:08

0:04:52

0:04:52

0:08:18

0:08:18

0:01:21

0:01:21

0:00:30

0:00:30

0:00:29

0:00:29

0:05:22

0:05:22

0:01:28

0:01:28

0:00:19

0:00:19

0:31:53

0:31:53

0:01:01

0:01:01

0:04:29

0:04:29

0:04:48

0:04:48

0:02:23

0:02:23

0:00:45

0:00:45

0:00:34

0:00:34

0:07:19

0:07:19

0:31:30

0:31:30

0:00:46

0:00:46