filmov

tv

Bakery Plant Visit Must watch | Start Your own Bakery Setup

Показать описание

A bakery plant, also known as a commercial bakery, is a facility that specializes in the production of bakery products such as bread, cakes, pastries, and other baked goods. The plant typically comprises several different areas, each with its own function, and operates using a combination of manual and automated processes. Here are some details about the different areas of a typical bakery plant:

Mixing and Preparation: This area is where the ingredients for the bakery products are measured, mixed, and prepared. This may involve mixing machines, dough dividers, moulders, and other equipment.

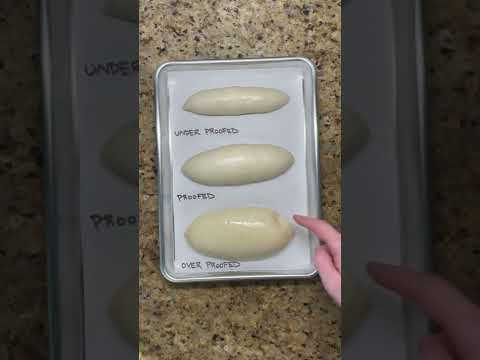

Proofing: The proofing area is where the dough is left to rest and rise, allowing it to ferment and develop flavor.

Baking: The baking area is where the dough is baked into finished products. This area may include commercial ovens, conveyors, and other equipment.

Cooling: The cooling area is where the freshly baked goods are allowed to cool before being packaged or further processed.

Packaging: The packaging area is where the baked goods are wrapped, labeled, and packaged for delivery to customers.

Storage: The storage area is where finished products are stored before distribution to retail outlets or other customers.

In addition to these areas, a typical bakery plant may also include quality control and sanitation areas to ensure that the products are safe and meet quality standards.

The exact layout and equipment of a bakery plant may vary depending on the specific products being produced and the scale of production.

Mixing and Preparation: This area is where the ingredients for the bakery products are measured, mixed, and prepared. This may involve mixing machines, dough dividers, moulders, and other equipment.

Proofing: The proofing area is where the dough is left to rest and rise, allowing it to ferment and develop flavor.

Baking: The baking area is where the dough is baked into finished products. This area may include commercial ovens, conveyors, and other equipment.

Cooling: The cooling area is where the freshly baked goods are allowed to cool before being packaged or further processed.

Packaging: The packaging area is where the baked goods are wrapped, labeled, and packaged for delivery to customers.

Storage: The storage area is where finished products are stored before distribution to retail outlets or other customers.

In addition to these areas, a typical bakery plant may also include quality control and sanitation areas to ensure that the products are safe and meet quality standards.

The exact layout and equipment of a bakery plant may vary depending on the specific products being produced and the scale of production.

Комментарии

0:02:14

0:02:14

0:07:06

0:07:06

0:03:18

0:03:18

0:02:14

0:02:14

0:06:21

0:06:21

0:54:08

0:54:08

0:08:42

0:08:42

0:00:32

0:00:32

0:07:28

0:07:28

0:00:14

0:00:14

0:00:59

0:00:59

0:08:22

0:08:22

0:36:19

0:36:19

0:01:49

0:01:49

0:30:01

0:30:01

0:00:30

0:00:30

0:15:36

0:15:36

0:00:44

0:00:44

0:00:58

0:00:58

0:00:44

0:00:44

0:13:53

0:13:53

0:14:50

0:14:50

0:00:56

0:00:56

0:00:21

0:00:21