filmov

tv

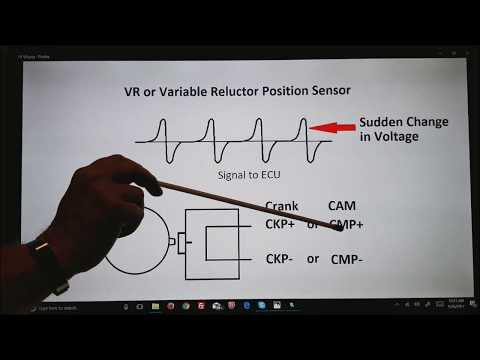

How Engine Sensors Work: Crankshaft, Camshaft, ABS. Magnetic Inductive Sensors.

Показать описание

Magnetic inductive sensors are very commonly used on modern vehicles and their failure can cause all kinds of problems: Difficulty starting, acceleration problems, engine speed 'hunting', increased fuel consumption and even the engine cutting out while driving.

For more information, see my website post about this video:

Cheers!

Chris 👍

--------------------

'Random Chris' is a Helvellyn Ltd brand. Disclaimer: Due to factors beyond the control of Helvellyn Ltd, we cannot guarantee against unauthorized modifications of this information, or improper use of this information. Helvellyn Ltd assumes no liability for property damage, injury or death incurred as a result of any of the information contained in this video. Helvellyn Ltd. recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, open flames, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of Helvellyn Ltd, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained in this video is the sole responsibility of the user and not Helvellyn Ltd. Disclosure: any links in this description may be affiliate links. If you decide to buy some items from them, Helvellyn Ltd may receive a small percentage compensation for having suggested the suppliers to you. (This costs you nothing) As an Amazon Associate we earn from qualifying purchases. Helvellyn Ltd only recommends suppliers and products which we believe in, so there is never any conflict of interest.

#enginesensors #electronics #electromagnetism

Комментарии

0:03:32

0:03:32

0:01:14

0:01:14

0:26:22

0:26:22

0:13:46

0:13:46

0:06:24

0:06:24

0:01:12

0:01:12

0:00:43

0:00:43

0:04:27

0:04:27

0:23:46

0:23:46

0:07:55

0:07:55

0:00:16

0:00:16

0:01:50

0:01:50

0:00:56

0:00:56

0:08:34

0:08:34

0:10:42

0:10:42

0:04:21

0:04:21

0:01:00

0:01:00

0:00:11

0:00:11

0:01:39

0:01:39

0:00:58

0:00:58

0:07:12

0:07:12

0:08:27

0:08:27

0:03:57

0:03:57

0:20:02

0:20:02