filmov

tv

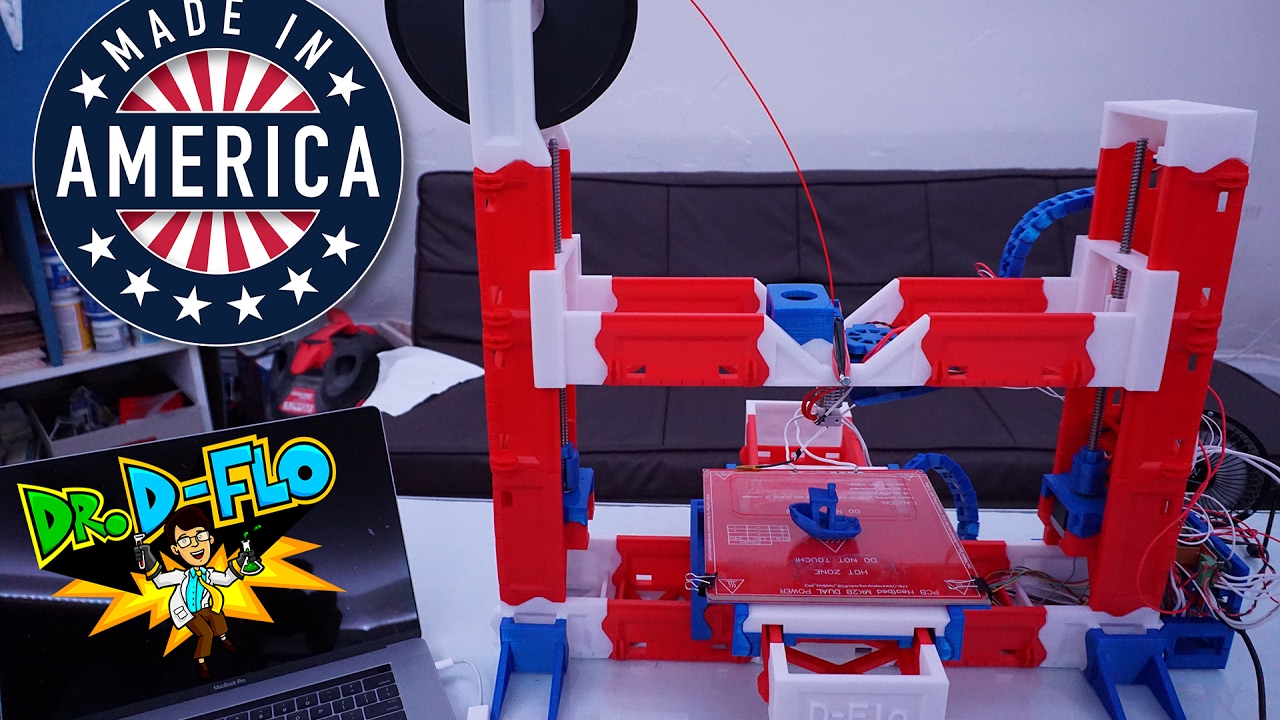

Self-Replicating 3D printer (Snappy)

Показать описание

If you bought one 3D printer could you print parts to make more 3D printers? The Replication Rapid-Prototyper Project (RepRap) is a group of 3D printer enthusiast who explore this possibility. Dr. D-Flo decided to build one of the most extreme RepRap designs known as Snappy. Snappy is a budget printer coming in at under $300. This low cost is afforded by using a 3D printer to print out 80% of the parts. Furthermore, Snappy requires almost no fasteners because the pieces snap together. Revarbat is the creator of this ingenious design. But how well does Snappy work?

Self-Replicating 3D printer (Snappy)

Snappy 3.1 self-replicating 3D printer - Self Replication and toughts on quality

Snappy 3.1 self-replicating 3D printer - Quick test

The Snappy 3 - Can It Self Replicate??? - Chris's Basement

Snappy 3.1 self-replicating 3D printer - Trouble ahead -X axis vibrations

Snappy 3.1 self-replicating 3D printer - vibrations solved and webcam

First test print on Snappy v1.5

BI V2.0 | First-Of-Its-Kind Self-replicating, High precision 3D Printer

Snappy 3D Printed Printer Update - Chris's Basement

A Self-Replicating 3D Printer: Video Demonstration

A 3D Printer Prints ...... ITSELF !! ( Self Replicating Terminator Style)

Snappy - 3D Printed - 3D Printer - Intro - Chris's Basement

3D Printing has gotten stale: The past, present and future of RepRap

A Self-Replicating 3D Printer: Introduction (ISEF 2021)

3D Printing WOOD !!! ⚠️ EXTREME Fast Wood ⚠️

Teebot3d self replication in progress.

Reprap Snappy 2 replicating itself

3D printer Self-Replicating

Snappy - 2019 Upgrade Tests

Part of a Dollo 3D printer

Snappy v3.0 is alive!

Snappy Reprap - Y Axis Build

Can you print a 3D Printer?

Snappy 3D Printed 3D Printer Build Day 1 - Chris's Basement

Комментарии

0:11:54

0:11:54

0:08:24

0:08:24

0:01:29

0:01:29

0:02:04

0:02:04

0:02:02

0:02:02

0:09:17

0:09:17

0:00:14

0:00:14

0:03:38

0:03:38

0:08:42

0:08:42

0:00:37

0:00:37

0:08:19

0:08:19

0:01:25

0:01:25

0:05:55

0:05:55

0:02:00

0:02:00

0:04:48

0:04:48

0:00:41

0:00:41

0:00:50

0:00:50

0:02:07

0:02:07

0:00:18

0:00:18

0:00:26

0:00:26

0:01:22

0:01:22

0:17:56

0:17:56

0:04:20

0:04:20

2:01:43

2:01:43