filmov

tv

How Copper Heatpipes Are Made | China Factory Tour (Cooler Master)

Показать описание

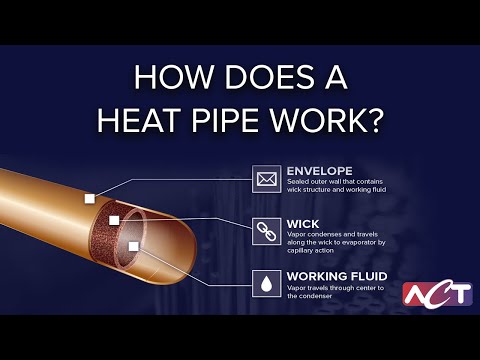

We show how CPU cooler and GPU cooler copper heatpipes are made by Cooler Master in HuiZhou, China. These automated factories near Shenzhen make the heatpipes.

Copper heatpipes contain liquid inside to accelerate heat dissipation by using the phase change to shed energy quickly. This video shows cross-sections of sintered copper heatpipes and talks about how much liquid (and what kind of liquid) is inside of a copper heatpipe. We also show the start-to-finish process of manufacturing heatpipes, which is part of the long process to make a CPU or GPU heatsink.

** Please like, comment, and subscribe for more! **

Follow us in these locations for more gaming and hardware updates:

Editorial, Video, Host: Steve Burke

Video Broll: Andrew Coleman

Links to Amazon and Newegg are typically monetized on our channel (affiliate links) and may return a commission of sales to us from the retailer. This is unrelated to the product manufacturer. Any advertisements or sponsorships are disclosed within the video ("this video is brought to you by") and above the fold in the description. We do not ever produce paid content or "sponsored content" (meaning that the content is our idea and is not funded externally aside from whatever ad placement is in the beginning) and we do not ever charge manufacturers for coverage.

Copper heatpipes contain liquid inside to accelerate heat dissipation by using the phase change to shed energy quickly. This video shows cross-sections of sintered copper heatpipes and talks about how much liquid (and what kind of liquid) is inside of a copper heatpipe. We also show the start-to-finish process of manufacturing heatpipes, which is part of the long process to make a CPU or GPU heatsink.

** Please like, comment, and subscribe for more! **

Follow us in these locations for more gaming and hardware updates:

Editorial, Video, Host: Steve Burke

Video Broll: Andrew Coleman

Links to Amazon and Newegg are typically monetized on our channel (affiliate links) and may return a commission of sales to us from the retailer. This is unrelated to the product manufacturer. Any advertisements or sponsorships are disclosed within the video ("this video is brought to you by") and above the fold in the description. We do not ever produce paid content or "sponsored content" (meaning that the content is our idea and is not funded externally aside from whatever ad placement is in the beginning) and we do not ever charge manufacturers for coverage.

Комментарии

0:09:35

0:09:35

0:08:29

0:08:29

0:02:54

0:02:54

0:00:19

0:00:19

0:02:16

0:02:16

0:00:11

0:00:11

0:00:15

0:00:15

0:00:18

0:00:18

0:01:00

0:01:00

0:00:57

0:00:57

0:00:22

0:00:22

0:00:23

0:00:23

0:02:10

0:02:10

0:00:30

0:00:30

0:00:12

0:00:12

0:00:10

0:00:10

0:05:16

0:05:16

0:00:21

0:00:21

0:00:24

0:00:24

0:00:16

0:00:16

0:00:36

0:00:36

0:02:24

0:02:24

0:00:14

0:00:14

0:00:08

0:00:08