filmov

tv

Stable eddy current induction levitation of aluminum disk

Показать описание

Aluminum disk floats stably on an alternating magnetic field. Induction heating of disk boils water and even makes tiny spots glow red when the current is concentrated.

For 60Hz levitation using microwave oven transformers:

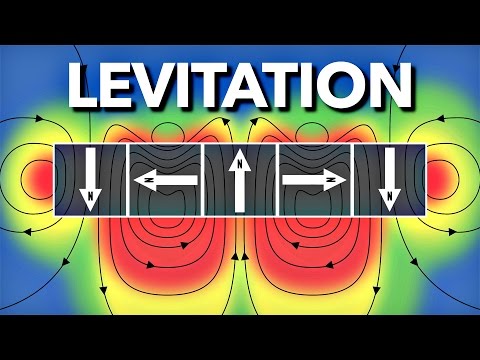

This is a flat coil much like an induction cook-top, except that the inner half of the coil is wound in one direction and the outer half in the other direction. This concentrates the magnetic field half-way out, making a stable pocket to float the aluminum disk.

The coil is 18 turns, 11 on the inner part and 7 on the outer part. ID is 50mm with 5mm thick ferrite disk inside that, 11 clockwise-wound turns to 117mm diameter, a ring of 5mm thick ferrite pieces, then the winding continues CCW for 7 turns from 137mm to 180mm final outside diameter. There's another layer of 5mm thick ferrites under the entire coil assembly. Total inductance is 32.8uH. The ferrites are 3F36 material, tiled and/or cut from 65 x 51mm rectangle blocks (meant for use in wireless phone... chargers). The drive circuit is resonant. The coil current is about 45A RMS at about 200V RMS at 23KHz. A somewhat lower frequency would be a bit more efficient, but I wanted to keep it above audible range. The drive is a single FET in a flyback style circuit. At 23KHz, the coil needed to be litz wire, which is home-made 380 strands of 35AWG wire. (My small prototypes for coil-geometry optimization used a low-voltage full-bridge in series with the resonant circuit, rather than a flyback FET in parallel. Either one can work.)

After completing this unit, I was regretting not starting with an induction cook-top, as that might have been less work. Besides changing the coil (reversing direction after using half the wire - a bit more than half the diameter), the iron-pan detector would need to be defeated. The remaining question is if the cook-top's electronics function correctly without the load of an iron pan. It might need to be powered from a lower line voltage, such as buying a 220V cook-top and using it at 120V. The internal low-voltage supply for the control electronics might have a problem at lower line voltage, or might not. It would take some experimenting.

For 60Hz levitation using microwave oven transformers:

This is a flat coil much like an induction cook-top, except that the inner half of the coil is wound in one direction and the outer half in the other direction. This concentrates the magnetic field half-way out, making a stable pocket to float the aluminum disk.

The coil is 18 turns, 11 on the inner part and 7 on the outer part. ID is 50mm with 5mm thick ferrite disk inside that, 11 clockwise-wound turns to 117mm diameter, a ring of 5mm thick ferrite pieces, then the winding continues CCW for 7 turns from 137mm to 180mm final outside diameter. There's another layer of 5mm thick ferrites under the entire coil assembly. Total inductance is 32.8uH. The ferrites are 3F36 material, tiled and/or cut from 65 x 51mm rectangle blocks (meant for use in wireless phone... chargers). The drive circuit is resonant. The coil current is about 45A RMS at about 200V RMS at 23KHz. A somewhat lower frequency would be a bit more efficient, but I wanted to keep it above audible range. The drive is a single FET in a flyback style circuit. At 23KHz, the coil needed to be litz wire, which is home-made 380 strands of 35AWG wire. (My small prototypes for coil-geometry optimization used a low-voltage full-bridge in series with the resonant circuit, rather than a flyback FET in parallel. Either one can work.)

After completing this unit, I was regretting not starting with an induction cook-top, as that might have been less work. Besides changing the coil (reversing direction after using half the wire - a bit more than half the diameter), the iron-pan detector would need to be defeated. The remaining question is if the cook-top's electronics function correctly without the load of an iron pan. It might need to be powered from a lower line voltage, such as buying a 220V cook-top and using it at 120V. The internal low-voltage supply for the control electronics might have a problem at lower line voltage, or might not. It would take some experimenting.

Комментарии

0:04:32

0:04:32

0:01:47

0:01:47

0:03:32

0:03:32

0:01:08

0:01:08

0:03:16

0:03:16

0:01:22

0:01:22

0:00:15

0:00:15

0:01:43

0:01:43

0:08:35

0:08:35

0:00:29

0:00:29

0:00:36

0:00:36

0:05:03

0:05:03

0:00:07

0:00:07

0:00:37

0:00:37

0:04:53

0:04:53

0:00:43

0:00:43

0:04:14

0:04:14

0:00:15

0:00:15

0:00:28

0:00:28

0:07:44

0:07:44

0:00:22

0:00:22

0:06:19

0:06:19

0:02:05

0:02:05

0:05:47

0:05:47