filmov

tv

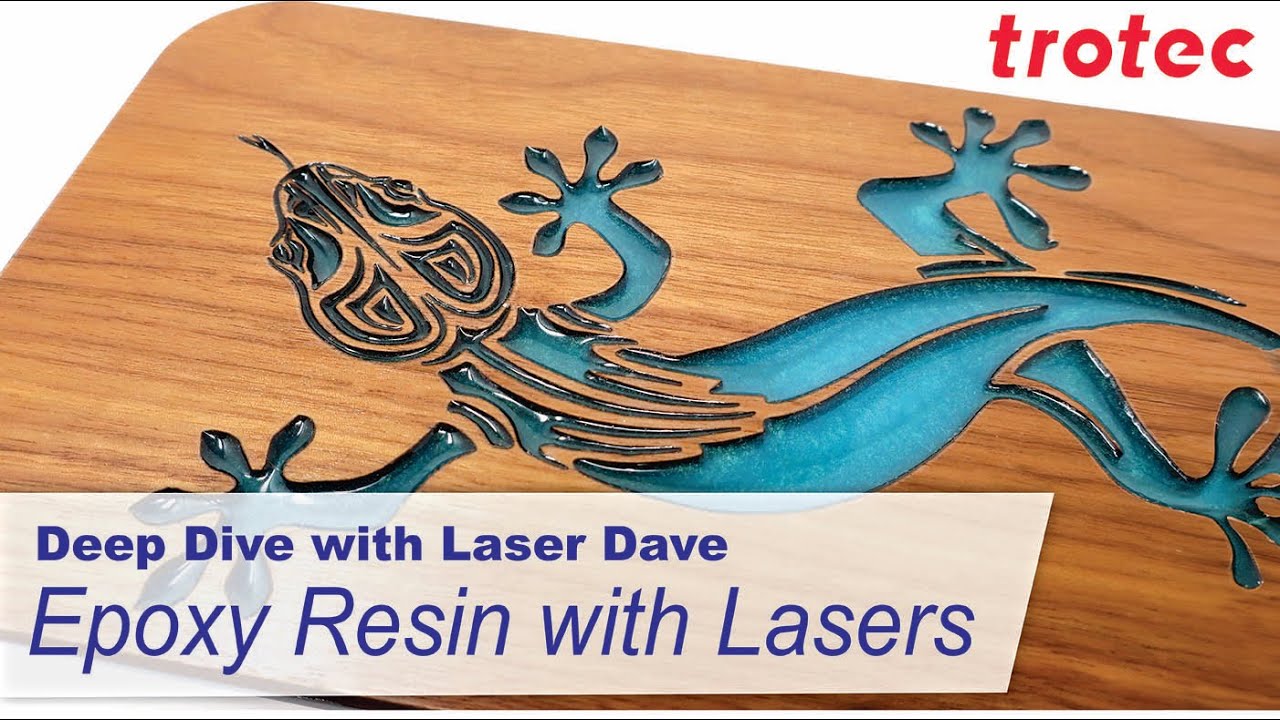

Deep Dive with Laser Dave - Epoxy Resin and Lasers

Показать описание

This video is a deep dive process of laser cutting and engraving when paired with the aesthetic appeal of epoxy resin, unlocking numerous artistic and commercial opportunities. The precision of laser technology, combined with the color and texture enhancements from traditional or UV epoxy resin inlays, produces eye-catching products. This combination captures artists' interest and presents a lucrative venture for entrepreneurs. UV epoxy resin can significantly speed up production, catering to various markets, from personalized items, Awards, and furniture to commercial signage, melding creativity with profitability.

Download the graphic design files used in this video:

Small Solid surface (I.E., Corian) Cutting boards and Trivets and small sheets:

Solid Woods:

Veneer Woods (Bamboo):

LET'S RESIN UV Resin Starter Kit:

UV Resin, 12 Colors Ultraviolet Epoxy Resin kit:

Epoxy liquid pigment (Color):

Epoxy Powder (metallic) color:

Hand Sander:

Sand Paper:

Butane Torch:

Rubber gloves:

Tabletop two-part (Non-UV) Epoxy:

Epoxy Resin Tape:

---------------------------------------------------------------------------------------------------------------

Be the first to get updates!

Download the graphic design files used in this video:

Small Solid surface (I.E., Corian) Cutting boards and Trivets and small sheets:

Solid Woods:

Veneer Woods (Bamboo):

LET'S RESIN UV Resin Starter Kit:

UV Resin, 12 Colors Ultraviolet Epoxy Resin kit:

Epoxy liquid pigment (Color):

Epoxy Powder (metallic) color:

Hand Sander:

Sand Paper:

Butane Torch:

Rubber gloves:

Tabletop two-part (Non-UV) Epoxy:

Epoxy Resin Tape:

---------------------------------------------------------------------------------------------------------------

Be the first to get updates!

Комментарии

0:12:56

0:12:56

0:09:37

0:09:37

0:07:23

0:07:23

0:11:00

0:11:00

0:06:06

0:06:06

0:04:43

0:04:43

0:07:51

0:07:51

0:08:30

0:08:30

2:54:54

2:54:54

0:11:38

0:11:38

0:12:46

0:12:46

0:14:24

0:14:24

0:06:19

0:06:19

0:08:28

0:08:28

0:03:38

0:03:38

0:07:28

0:07:28

0:09:14

0:09:14

0:11:23

0:11:23

0:05:51

0:05:51

0:07:02

0:07:02

0:08:34

0:08:34

0:09:46

0:09:46

0:05:17

0:05:17

0:09:21

0:09:21