filmov

tv

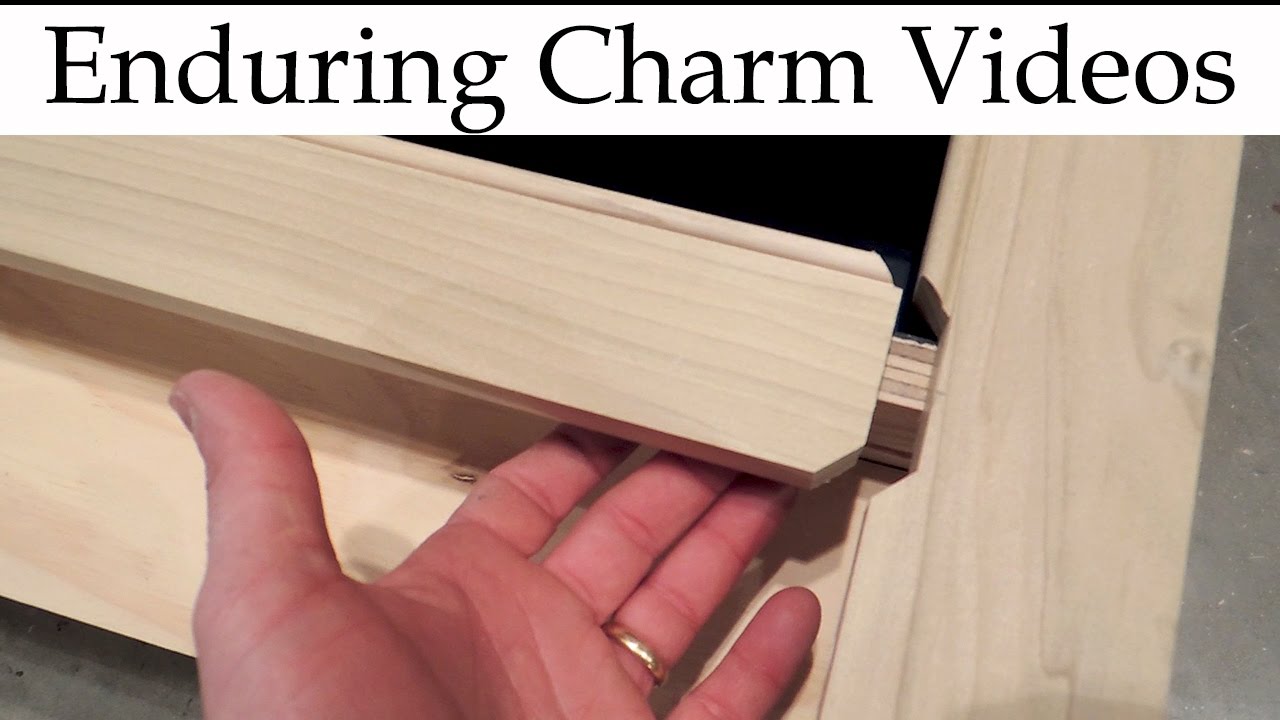

Cabinet Beaded Face Frames With A Simple System

Показать описание

Traditional cabinets often have a bead detail around the drawer and door edges. The original method of doing this was to apply a bead moulding or sometimes to scratch the bead into the frame in more primitive styles. With modern routers we can cut beads easily enough, but what is the best way to miter the stiles and rails together? In this video I'll show you how I'm accomplishing this traditional detail for some kitchen cabinets.

►To purchase:

As an Amazon associate I earn from qualifying purchases.

►To purchase:

As an Amazon associate I earn from qualifying purchases.

HOFFMANN MU-3 Jointer and Notch Guillotine for Beaded Cabinet Frames

Cabinet Beaded Face Frames With A Simple System

THE DETAILS YOU NEED TO MAKE THE PERFECT BEAD INSET CABINETS

Kreg PRS1200 Precision Beaded Face-Frame System Review

Benchmark Custom Cabinet - Beaded inset frame custom cabinetry manufactured in Tacoma, Washington

Cabinetmaker Creating Beaded Face Frames For a Custom Cabinet Project

Adjoining Inset Cabinets

Kreg Beaded Face Frame Review.mov

Beaded Face Frames The Simplest Way

Dura Supreme Crestwood Dempsey door & drawer style, beaded inset cabinetry in Rock Bottom finish

BEAD-INSET CABINET pt 2 **BUILD DETAILS *MADE SIMPLE

How to build Beaded Frame Inset Custom Cabinets

Easy router jig for jack miter for beaded face frame cabinets

Beaded Face Frame Furniture - How to make

KREG High Speed Beaded Face Frames - On Your Router!

Beaded face frame for a custom cabinetry. Current woodworking project

Making a beaded face frame! #cabinetmaking #woodworking #woodwork #cabinetshop #kitchens

Intelligent beaded face frames | CABINET VISION 2022.1

Essential Woodworking Tools Every Craftsman Needs#4

Beaded Face Frame Made Lean!

Easy Cabinet Face Frames For Beginners

How To Make Beaded Face Frames

DIY Beaded Face Frame Jig for Cabinets (Kreg Jig alternative)

Nantucket Homes - Cabinets: Beaded and Inset

Комментарии

0:02:49

0:02:49

0:12:32

0:12:32

0:22:51

0:22:51

0:03:01

0:03:01

0:01:41

0:01:41

0:18:20

0:18:20

0:02:13

0:02:13

0:07:15

0:07:15

0:03:55

0:03:55

0:02:01

0:02:01

0:13:03

0:13:03

0:03:29

0:03:29

0:03:49

0:03:49

0:10:14

0:10:14

0:02:54

0:02:54

0:00:29

0:00:29

0:04:12

0:04:12

0:01:08

0:01:08

0:00:40

0:00:40

0:03:38

0:03:38

0:06:42

0:06:42

0:17:11

0:17:11

0:16:02

0:16:02

0:01:42

0:01:42