filmov

tv

What is HMI? | Human Machine Interface

Показать описание

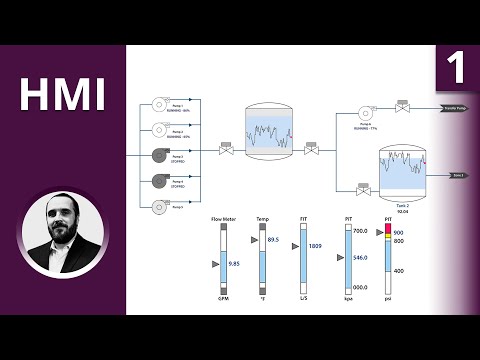

🎥 An HMI or Human Machine Interface is simply a control unit that facilitates the integration of operators into complicated industrial processes by delivering a user-friendly dashboard.

By watching this video, you’ll get the answer to these questions:

- What is HMI?

- Why is HMI used?

- Where is HMI used?

- What is HMI design?

- How does HMI work?

- What is HMI software?

- What is HMI Hardware?

- What is the HMI function?

- What does HMI stand for?

- What are the types of HMI?

- What is HMI programming?

- What is the purpose of HMI?

- What are the advantages of HMI?

- How does HMI communicate with a PLC?

======================================================

💬 Video Summary:

HMI Explained

- Because PLC is just hardware, it cannot display signal values instantly to operators unless technical staff with a personal computer and necessary software establish a connection to the PLC and check the program status online to keep an eye on signal values.

- It is not a practical method for operations employees to regularly check what the PLC is doing, and that’s where a human-machine interface, or HMI for short, comes into play.

HMI Types

- A variety of HMIs is available in an industrial setting, such as touchscreen, screen with buttons, built-in screen, handheld screen, computer screen, and mobile screen

HMI Hardware

- The hardware layouts of most actual HMIs are similar, which include the following: screen for monitoring, control panel, and communication port

HMI Software

- The software configurations of most genuine HMIs are alike, which applies in two steps.

- First, development. A personal computer is used to program the HMI through special software. And the Second step that applies in the HMI software configuration is runtime.

HMI Design

- If you are interested in HMI programming, you should consider some essential design tips, such as user awareness, visibility, simplicity, and consistency

HMI to PLC communication

- For the HMI to provide an interface for a manufacturing line, the HMI usually needs to be connected to a programmable logic controller or PLC.

- Compatibility between the HMI and PLC is required, meaning they must be able to communicate with one another.

HMI Operation:

- The PLC will receive information from sensors and will start processing the collected data into logical combinations.

- As soon as the PLC provides real-time data directly to the HMI, the HMI is used to convert complicated process variables into information in the form of a graphical way.

- At this point, the operator can send commands through the HMI screen, and the HMI will transfer user inputs to the PLC to be processed into the logical format.

- Then the PLC sends translated data to the actuators to be executed over a given industrial process system.

HMI Function

- Most HMIs have the same basic and extensively utilized functionality, such as monitoring, controlling, alarms management, data logging, and troubleshooting

HMI Advantages:

- And finally, let us talk about the benefits of implementing HMIs, including increased visibility, enhanced efficiency, decreased downtime, ensure safety, ease-of-use, and cost reduction.

======================================================

⏰ TABLE OF CONTENTS ⏰

00:00 What is an HMI?

00:55 HMI Types

01:57 HMI Hardware

02:21 HMI Software

03:39 HMI Interface with PLC

04:54 HMI Functionality

06:08 HMI Benfits

======================================================

🔥 Have you seen our recent popular videos? You can watch them here:

======================================================

💡 If you enjoyed this video and want to follow our upcoming videos, subscribe to this YouTube channel and relax your mind:

======================================================

#Automatedo #hmi #hmiprogramming

By watching this video, you’ll get the answer to these questions:

- What is HMI?

- Why is HMI used?

- Where is HMI used?

- What is HMI design?

- How does HMI work?

- What is HMI software?

- What is HMI Hardware?

- What is the HMI function?

- What does HMI stand for?

- What are the types of HMI?

- What is HMI programming?

- What is the purpose of HMI?

- What are the advantages of HMI?

- How does HMI communicate with a PLC?

======================================================

💬 Video Summary:

HMI Explained

- Because PLC is just hardware, it cannot display signal values instantly to operators unless technical staff with a personal computer and necessary software establish a connection to the PLC and check the program status online to keep an eye on signal values.

- It is not a practical method for operations employees to regularly check what the PLC is doing, and that’s where a human-machine interface, or HMI for short, comes into play.

HMI Types

- A variety of HMIs is available in an industrial setting, such as touchscreen, screen with buttons, built-in screen, handheld screen, computer screen, and mobile screen

HMI Hardware

- The hardware layouts of most actual HMIs are similar, which include the following: screen for monitoring, control panel, and communication port

HMI Software

- The software configurations of most genuine HMIs are alike, which applies in two steps.

- First, development. A personal computer is used to program the HMI through special software. And the Second step that applies in the HMI software configuration is runtime.

HMI Design

- If you are interested in HMI programming, you should consider some essential design tips, such as user awareness, visibility, simplicity, and consistency

HMI to PLC communication

- For the HMI to provide an interface for a manufacturing line, the HMI usually needs to be connected to a programmable logic controller or PLC.

- Compatibility between the HMI and PLC is required, meaning they must be able to communicate with one another.

HMI Operation:

- The PLC will receive information from sensors and will start processing the collected data into logical combinations.

- As soon as the PLC provides real-time data directly to the HMI, the HMI is used to convert complicated process variables into information in the form of a graphical way.

- At this point, the operator can send commands through the HMI screen, and the HMI will transfer user inputs to the PLC to be processed into the logical format.

- Then the PLC sends translated data to the actuators to be executed over a given industrial process system.

HMI Function

- Most HMIs have the same basic and extensively utilized functionality, such as monitoring, controlling, alarms management, data logging, and troubleshooting

HMI Advantages:

- And finally, let us talk about the benefits of implementing HMIs, including increased visibility, enhanced efficiency, decreased downtime, ensure safety, ease-of-use, and cost reduction.

======================================================

⏰ TABLE OF CONTENTS ⏰

00:00 What is an HMI?

00:55 HMI Types

01:57 HMI Hardware

02:21 HMI Software

03:39 HMI Interface with PLC

04:54 HMI Functionality

06:08 HMI Benfits

======================================================

🔥 Have you seen our recent popular videos? You can watch them here:

======================================================

💡 If you enjoyed this video and want to follow our upcoming videos, subscribe to this YouTube channel and relax your mind:

======================================================

#Automatedo #hmi #hmiprogramming

Комментарии

0:06:46

0:06:46

0:07:52

0:07:52

0:02:20

0:02:20

0:03:37

0:03:37

0:07:52

0:07:52

0:03:23

0:03:23

0:05:42

0:05:42

0:15:25

0:15:25

0:06:02

0:06:02

0:00:53

0:00:53

0:06:44

0:06:44

0:04:03

0:04:03

0:02:28

0:02:28

0:01:39

0:01:39

0:05:45

0:05:45

0:00:42

0:00:42

0:04:01

0:04:01

0:02:00

0:02:00

0:09:38

0:09:38

0:01:46

0:01:46

0:09:17

0:09:17

1:05:41

1:05:41

0:08:46

0:08:46

0:03:52

0:03:52