filmov

tv

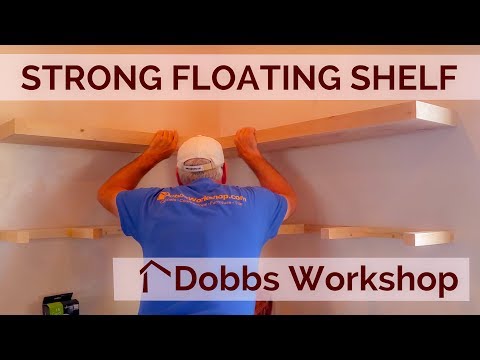

Strong Floating Shelves - The Strongest Option

Показать описание

First video on Strong Floating Shelves:

After experimenting with floating shelves for several years now, I've found ways to make them strong using lag bolts and wooden dowels. But the strongest option yet that I explore in this video uses 5/8 inch steel all thread rods as shelf supports for floating shelves. Wood works fine, but it doesn't really compare to the strength that you get with steel rods.

After experimenting with floating shelves for several years now, I've found ways to make them strong using lag bolts and wooden dowels. But the strongest option yet that I explore in this video uses 5/8 inch steel all thread rods as shelf supports for floating shelves. Wood works fine, but it doesn't really compare to the strength that you get with steel rods.

Strong Floating Shelves - The Strongest Option

Why don't people use these for floating shelves?

2 Ways To Do Floating Shelves - Which Is Stronger?

Strong Floating Shelves

DIY Floating Shelves - SUPER STRONG + THIN

How To Hang a Floating Lack Shelf a Stronger Way

How strong is an IKEA LACK floating shelf on plasterboard ??

How Can Floating Shelves Hold A Person?

Level Up Your Space with Greenco's Corner Shelf! #gadgets #amazongadgets #youtubeshorts

Searching For Better Floating Shelf Hardware

Easy DIY Floating Shelves | The Best Floating Shelf Bracket?

3 Ways to Build Floating Shelves

DIY Floating Wall Shelves and Hardware for Heavy Duty Shelves

4 Floating Shelves From Beginner to Expert Level

How to Build Super Strong Floating Shelves! Alcove Shelves!#carpentry #woodworking#tips#tooltips#diy

This floating shelf is held up by 2 screws.

Ikea floating shelf installation

These Strong Floating Shelves Only Use 4 Screws

Strong Floating Shelf Design Options

Floating Shelves without the expensive hardware!

How I Made A Floating Shelf Strong Enough To Hang Onto

Impressive INVISIBLE Floating Shelf Support Bracket | Woodworking Project | Tips & Tricks

Our Heavy Duty Floating Shelf Brackets | The Tree Knot 🌲 #floatingshelves

How To Make Super Strong and Thin Floating Shelves

Комментарии

0:14:33

0:14:33

0:18:13

0:18:13

0:06:26

0:06:26

0:06:06

0:06:06

0:15:06

0:15:06

0:05:06

0:05:06

0:19:17

0:19:17

0:12:41

0:12:41

0:00:25

0:00:25

0:24:10

0:24:10

0:07:08

0:07:08

0:18:51

0:18:51

0:11:54

0:11:54

0:18:14

0:18:14

0:03:41

0:03:41

0:05:15

0:05:15

0:00:51

0:00:51

0:04:20

0:04:20

0:07:48

0:07:48

0:12:42

0:12:42

0:08:21

0:08:21

0:05:34

0:05:34

0:00:13

0:00:13

0:16:54

0:16:54