filmov

tv

Boring out Ford 302 on my  milling machine

Показать описание

Boring out Ford 302 on my  milling machine

Boring out old Ford V8

sleeving a Bore for a 302 ford at precision machine works!!

Honing For The Home Engine Builder

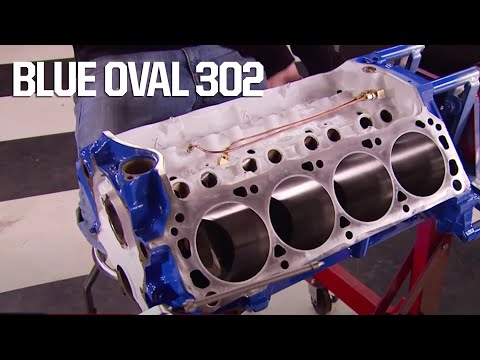

Ford 302 Small Block Becomes A 400+ HP Street Fighter - Horsepower S14, E1

Tearing Down The Small Block Ford 302 Finding Damaged Cylinder Wall (bore)

283 bored out to 302 sbc

Engine block transformation after chemical dipping

Just another Boring day @ the shop Big bore 771, 64x 771 & Ford 302 #engine #machining #porting ...

Boring a 302 ford block for humpty dumpty.

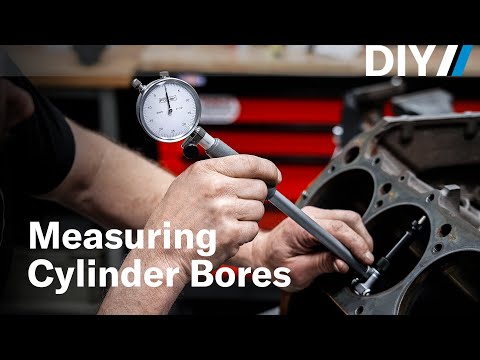

Measuring cylinder bores using a dial bore gauge | DIY

DIY CYLINDER BORE CHECK: How to measure OUT OF ROUND, TAPER, and REBORE size - STEP BY STEP GUIDE

ford 302 bored 060 over build by leal performance teaser(sonic tested)

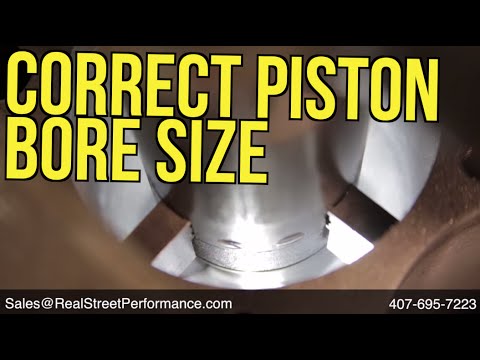

How to select the Correct Piston Bore Size for your Engine Build - Real Street Performance

1986 Ford Mustang GT For Sale~Freshly Rebuild 302 Bored to 306~Full Mechanical Restoration

LOW-BUCK 302 FORD HEAD UPGRADE

Boring out Aluminum Bore Cylinder .020' with Lisle 16000 Hone (same process for cast iron sleev...

HOW TO BUILD CHEAP 5.0L FORD POWER! WHAT DOES IT TAKE TO ADD POWER TO YOUR DAILY DRIVEN SB FORD?

302 ford bored 60 over first start up

Building The Best BUDGET 'BANG for BUCK' 302 Motor! SECRET RECIPE INSIDE!

91 ford fr150 with a rebuilt 302 big block bored over

1966 Ford Mustang V8 289 V8 BORED TO A 302 www.mroldcar.com 1-214-680-8128

Chamfering cylinders after bore .060 over on a 302 Ford block

The Ford 302 Engine: Everything You Need To Know

Комментарии

0:00:58

0:00:58

0:00:12

0:00:12

0:00:17

0:00:17

0:08:16

0:08:16

0:18:04

0:18:04

0:07:52

0:07:52

0:00:21

0:00:21

0:00:12

0:00:12

0:00:30

0:00:30

0:01:00

0:01:00

0:09:11

0:09:11

0:10:52

0:10:52

0:00:06

0:00:06

0:04:32

0:04:32

0:06:15

0:06:15

0:14:23

0:14:23

0:18:21

0:18:21

0:11:23

0:11:23

0:00:49

0:00:49

0:17:52

0:17:52

0:00:40

0:00:40

0:00:28

0:00:28

0:00:49

0:00:49

0:08:59

0:08:59