filmov

tv

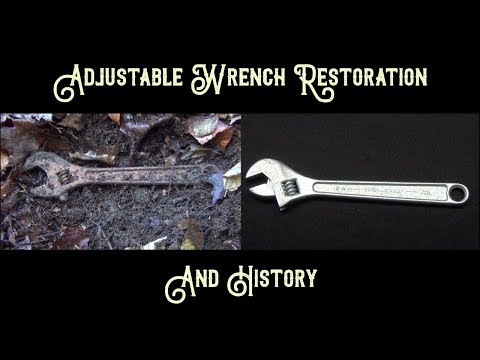

Adjustable Wrench Restoration and History

Показать описание

This is the history of the adjustable wrench and restoration.

The invention of the first adjustable wrench, also known as the adjustable spanner, or English Key in many parts of the world, was commonly credited to an English engineer named Richard Clyburn, in 1842. Another English engineer, Edwin Budding, who invented the first lawnmower in 1830, is also credited with the invention of the adjustable spanner in 1842. Though these two inventors were credited, if you look at the 1857 patent by Edward J. Worcester, you see a strong resemblance to today's adjustable wrenches, and it probably had a lot of influence on the design, and deserves mention. The crescent wrench's exact origins are actually still somewhat obscure and were more likely the result of an amalgamation of designs. In 1891, the Clyburn adjustable wrench was further improved by Swedish inventor JP Johansson, into a form that closely resembles its modern form, though the mechanism appears to have been strongly influenced by earlier designs. Johansson was a holder of at least 100 patents, and the founder of the company that would later become known as Bahco. Around the same time his adjustable wrench patent was granted, Johansson sold his marketing rights to BA Hjorth and Co to produce his wrenches, and sell them under the Bahco trademark, which was an acronym of the BA Hjorth and Co name. Under Johansson's supervision, Bahco made further improvements to the wrench, which included reducing the 45 degree handle to jaw angle, to 15 degrees, which was more user friendly. They also introduced the I beam handle, which allowed the wrench to be much lighter and more easily gripped, and likely also reduced the amount of steel needed during manufacturing. By 1964, Bahco had manufactured over 35 million wrenches, and is widely accepted as the first manufacturer of the adjustable wrench, or the crescent wrench that we're familiar with, and remains the largest producer of the adjustable wrench outside of the US.

The Crescent Tool Co of Jamestown NY was founded in 1907 by Karl Peterson. In 1910 it began marketing an adjustable wrench with features much like those made by Bahco. Even though there were many competing adjustable wrench manufacturers in the early 20th century, Crescent maintained a strong position in the market for many decades due to their high quality. Crescent received name brand recognition when Charles Lindbergh was quoted as saying he only brought ‘gasoline, sandwiches, a bottle of water, and a Crescent wrench and pliers’ on his flight across the Atlantic in 1927. It has also been said that by 1908 that a “Crescent adjustable wrench and pliers were being supplied with every Model-T Ford. The Crescent name became synonymous with the adjustable wrench in the US.

One of those competitors was the J H Williams Company, who began offering an adjustable wrench in 1930. Although it resembled the Bahco and Crescent wrenches, one unique design improvement set it apart from its predecessors. That is, the keyway for the adjustable jaw on the J H Williams wrench had a D shaped profiled keyway, whereas the other brands featured a round profile. This is important because the D shaped keyway gave the moveable jaw flat contact surfaces to transfer pressure, which reduced lateral keyway deflection, and therefore reduced jaw deflection.

The wrench I'm restoring in this video is the model AP-12 Super Adjustable, manufactured by the J H Williams company, and is a lucky find, because it is known as a high quality wrench. The AP-12 started production in 1968, though I don't know the specific year this particular wrench was made.

Although these wrenches were typically chrome plated at the factory, I don't have the capability do that in my own shop, at least not yet. Still, I wanted to restore this tool, and make it look as nice as I could, meanwhile protecting the finish from further corrosion. Zinc plating works very well for that, so that is what I'm using. This is the story of my AP-12 Super Adjustable wrench restoration.

The first thing I needed to do was to rinse off the excess dirt, and see the extent of the rust.

I quickly found that the threaded pin holding the scroll wheel in place was stripped. That was a little difficult to remove, but nothing that pounding it against the workbench wouldn't solve.

I used coarse crushed glass blasting media to remove some of the heavier scale. I only added a few pounds of it to my blasting cabinet so that it would break down quickly. As it broke down, the finer media was able to clean out any smalls pits in the wrench.

I knew that I wouldn't be able to get rid of all the pits without removing a lot of material, so I only concentrated on leveling the surface and removing some of the smaller voids.

Комментарии

0:15:42

0:15:42

0:01:01

0:01:01

0:08:22

0:08:22

0:11:51

0:11:51

0:14:33

0:14:33

0:08:34

0:08:34

0:07:56

0:07:56

0:09:09

0:09:09

0:08:54

0:08:54

0:06:12

0:06:12

0:02:48

0:02:48

0:11:49

0:11:49

0:11:38

0:11:38

0:01:00

0:01:00

0:08:05

0:08:05

0:06:54

0:06:54

0:18:05

0:18:05

0:45:53

0:45:53

0:20:06

0:20:06

0:18:13

0:18:13

0:10:41

0:10:41

0:17:02

0:17:02

0:06:58

0:06:58

0:26:08

0:26:08