filmov

tv

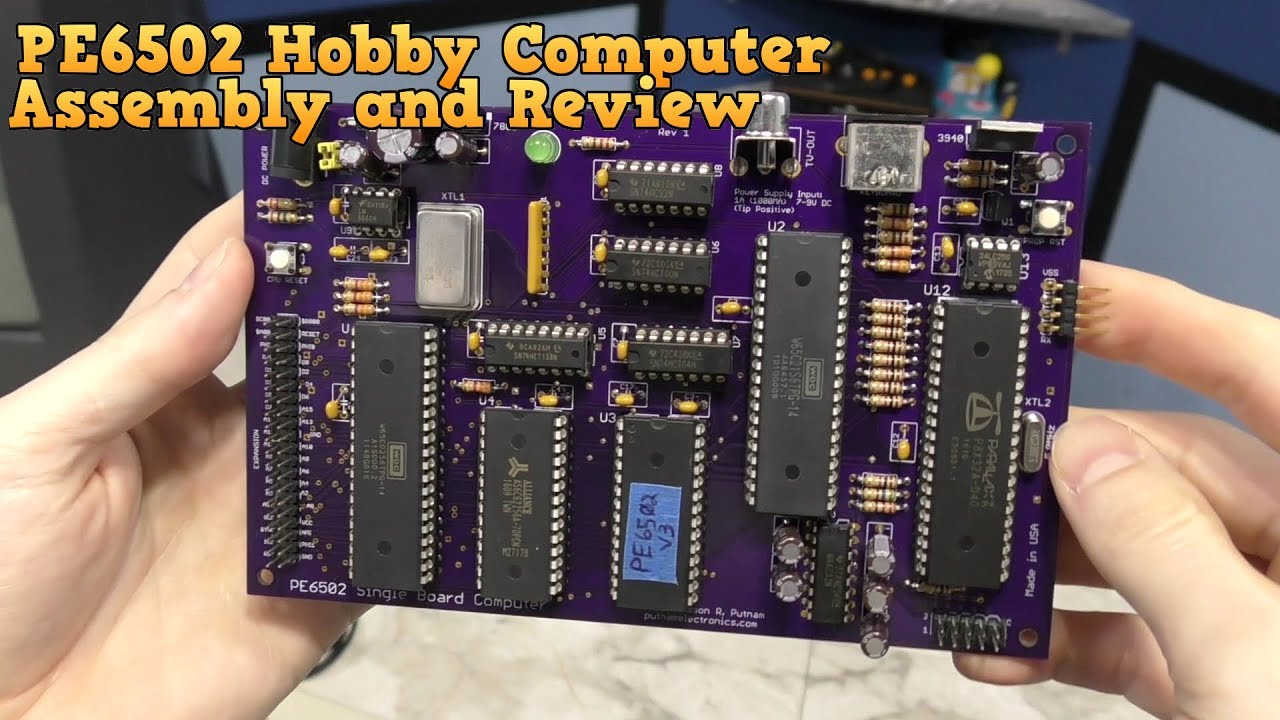

Assembly and Review - PE6502 Hobby Computer

Показать описание

Support this channel on Patreon

Visit my website for cool gear:

For more information on the PE6502 computer, visit:

In this episode I build the Putnam Electronics PE6502 hobby computer and test out it's capabilities!

Visit my website for cool gear:

For more information on the PE6502 computer, visit:

In this episode I build the Putnam Electronics PE6502 hobby computer and test out it's capabilities!

Assembly and Review - PE6502 Hobby Computer

PE6502 Usage Demo, and new PutnamElectronics Forums

PE6502 computer plays Microchess!

(180210) Playing with NES and 6502 Assembly

Pocket Sized Z80 Computer Review

EEVblog #1080 - Gigatron TTL RISC Kit Computer Review

Writing NES Games! With Assembly!!

SmartyKit – Inside 6502 CPU. Crush test of legendary processor

Assembly language vs. machine code — 6502 part 3

Assembling the Gigatron TTL Computer (or ... trying to!) pt 1/2

I was sent Ben Eater's 6502 computer kit!

The Commander X16 is Finally Reviewed!

PE6502 SwinSID Soundcard, Part 3

6502 Computer - Designing a 6502 computer

Khadas Edge & Captain Review

Program 6502 assembly language ( NES )

Mike builds an Apple 1 - pt 2 assembling the Replica 1

R6502AP

6502 video 1. Building and soldering the Putnam 6502 kit 8 bit 6502 CPU computer.

MOnSter 6502 Update #1

6502 40th Anniversary VCF Badge kit unboxing and review

Tesla Coil DIY KIT (Music Plasma Speaker) with detailed assembly

IBM 5150 Clone Kit - Part 3 - Motherboard Build - STB70

Is this the FASTEST and CHEAPEST 8-Bit Computer Ever?

Комментарии

0:25:07

0:25:07

0:09:50

0:09:50

0:06:32

0:06:32

0:00:17

0:00:17

0:25:07

0:25:07

0:18:13

0:18:13

0:11:40

0:11:40

0:05:49

0:05:49

0:15:35

0:15:35

0:08:13

0:08:13

0:02:11

0:02:11

0:10:53

0:10:53

0:08:05

0:08:05

0:07:32

0:07:32

0:05:14

0:05:14

0:25:50

0:25:50

0:39:00

0:39:00

0:00:42

0:00:42

0:02:31

0:02:31

0:02:19

0:02:19

0:14:56

0:14:56

0:06:57

0:06:57

0:27:57

0:27:57

0:28:43

0:28:43