filmov

tv

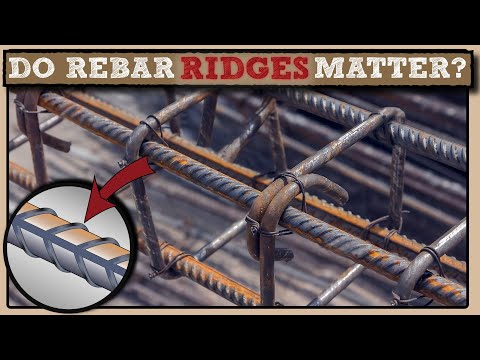

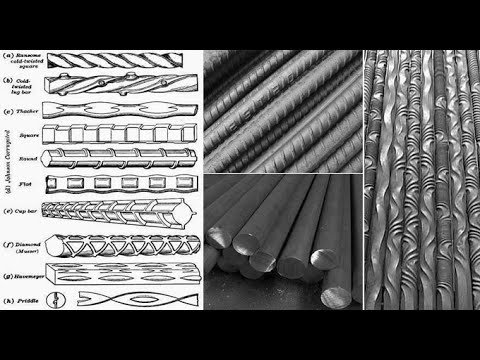

Why does concrete reinforcement have deformations?

Показать описание

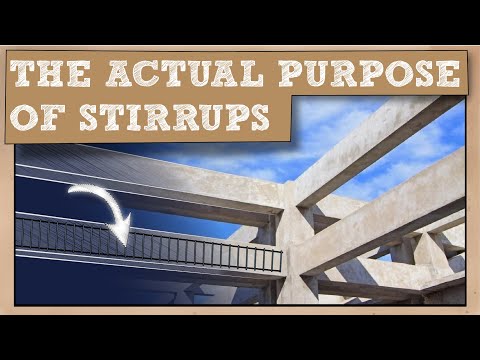

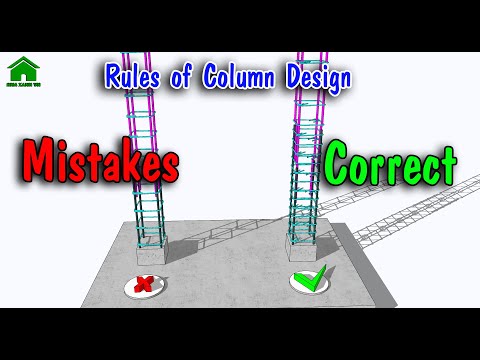

The tandem of concrete and steel works well in resisting loads since concrete is amazing at resisting compressive loads while the steel bars are great at taking care of the tensile forces. The combination of these two constriction materials gives rise to reinforced concrete that has been a central figure in the construction of modern society. But small details around this composite material have evolved over time. For example, in the early days of concrete construction, the steel reinforcement used to be plain (undeformed). Later on, it was found out that this is not the optimal way to reinforce concrete. This video investigates and points out the effects of using deformed vs. plain rebar on the strength of the reinforced concrete beams.

BUY ME A COFFEE LINK:

If you enjoy our work, you can buy us a coffee on the link below:

References:

[1] J. Maffei, "The Seismic Evaluation and Retrofitting of Bridges," University of Canterbury, Christchurch, New Zealand, 1996.

[2] S. Brzev and J. Pao, "Shear Design of Beams and One-Way Slabs," in Reinforced Concrete A Practical Approach, Toronto, Prentice Hall, 2009, pp. 260-315.

[3] A. P. Clark, "Bond of Concrete Reinforcing Bars," Journal of Research of the National Bureau of Standards, vol. 43, pp. 565-579, 1949.

BUY ME A COFFEE LINK:

If you enjoy our work, you can buy us a coffee on the link below:

References:

[1] J. Maffei, "The Seismic Evaluation and Retrofitting of Bridges," University of Canterbury, Christchurch, New Zealand, 1996.

[2] S. Brzev and J. Pao, "Shear Design of Beams and One-Way Slabs," in Reinforced Concrete A Practical Approach, Toronto, Prentice Hall, 2009, pp. 260-315.

[3] A. P. Clark, "Bond of Concrete Reinforcing Bars," Journal of Research of the National Bureau of Standards, vol. 43, pp. 565-579, 1949.

Комментарии

0:03:39

0:03:39

0:08:11

0:08:11

0:07:49

0:07:49

0:08:11

0:08:11

0:07:38

0:07:38

0:09:01

0:09:01

0:04:19

0:04:19

0:04:20

0:04:20

0:03:55

0:03:55

0:05:02

0:05:02

0:10:01

0:10:01

0:06:42

0:06:42

0:00:17

0:00:17

0:00:20

0:00:20

0:00:07

0:00:07

0:00:39

0:00:39

0:00:14

0:00:14

0:00:14

0:00:14

0:00:06

0:00:06

0:00:16

0:00:16

0:00:21

0:00:21

0:00:16

0:00:16

0:00:16

0:00:16

0:00:06

0:00:06