filmov

tv

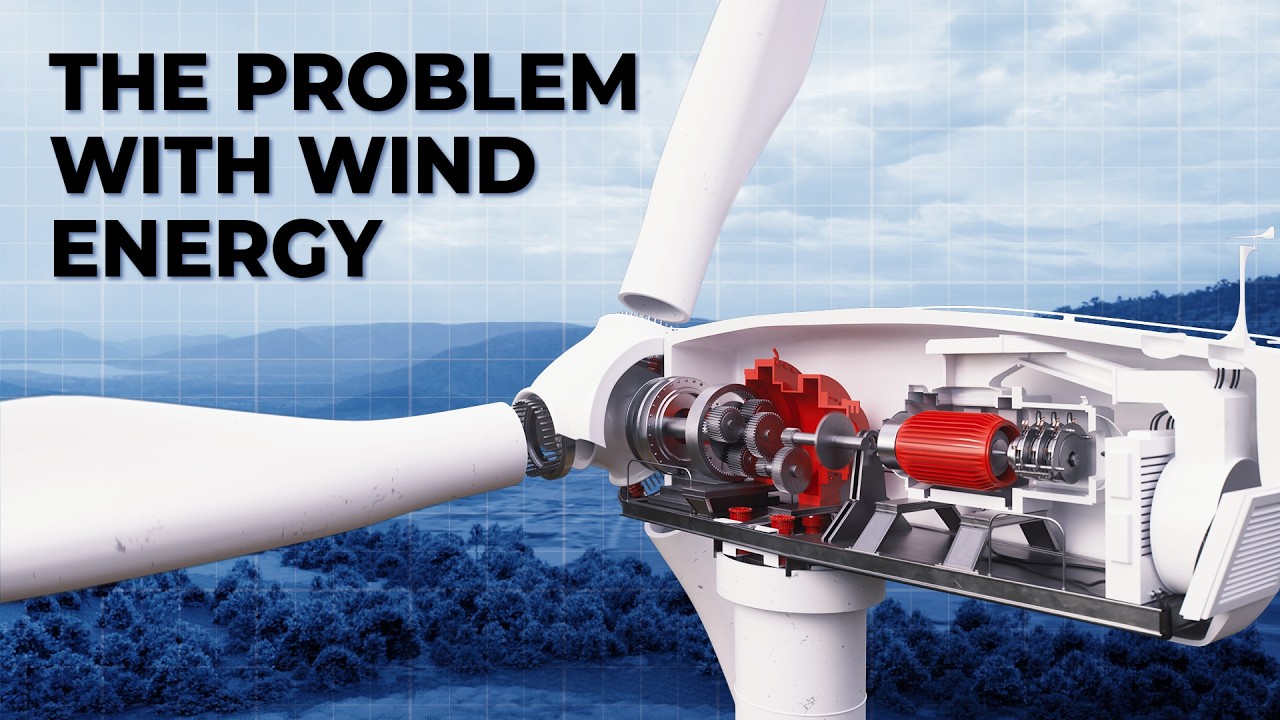

The Problem with Wind Energy

Показать описание

Links to everything I do:

Credits:

Producer/Writer/Narrator: Brian McManus

Head of Production: Mike Ridolfi

Editor: Dylan Hennessy

Writer/Research: Josi Gold

Animator: Eli Prenten

Animator: Stijn Orlans

Sound and Production Coordinator: Graham Haerther

Sound: Donovan Bullen

Thumbnail: Simon Buckmaster

Head of Moral: Shia LeWoof

Select imagery/video supplied by Getty Images

Thank you to AP Archive for access to their archival footage.

Thank you to my patreon supporters: Abdullah Alotaibi, Adam Flohr, Henning Basma, Hank Green, William Leu, Tristan Edwards, Ian Dundore, John & Becki Johnston. Nevin Spoljaric, Jason Clark, Thomas Barth, Johnny MacDonald, Stephen Foland, Alfred Holzheu, Abdulrahman Abdulaziz Binghaith, Brent Higgins, Dexter Appleberry, Alex Pavek, Marko Hirsch, Mikkel Johansen, Hibiyi Mori. Viktor Józsa, Ron Hochsprung

The Problem with Wind Energy

What's Wrong with Wind and Solar? | 5 Minute Video

The truth about wind turbines - how bad are they?

The Problem With Renewable Energy (and how we're fixing it)

Wind power's unsolved problem

The Real Reason America Has Turned Its Back On Wind Power Energy

The Tech That Could Fix One of Wind Power's Biggest Problems

Here’s how wind farms affect our environment | JUST THE FAQS

Top news stories in Connecticut for Aug. 7, 2024 at 6 p.m.

Renewable Energy is The Scam We All Fell For

The Pros and Cons of Wind Energy

This is what's REALLY holding back wind and solar

The Glaring Engineering Mistake That Made Wind Turbines Inefficient | Massive Engineering Mistakes

Wind energy racket exposed at last

How Bad Is The Wind Turbine Trash Problem? And Can We Solve It? | World Wide Waste

How We Solved The Home Wind Turbine Problem

How to fix clean energy’s storage problem

The Biggest Lie About Renewable Energy

There are 'problems' needing to be addressed with offshore wind farms

How Wind Turbines Really Work: The Hidden Secrets

Is offshore wind the energy of the future?

All About Wind Energy

Small Wind Turbine: Success or Failure? Do not make those Mistakes

How Wind Turbines Make You Sick

Комментарии

0:16:47

0:16:47

0:05:36

0:05:36

0:11:06

0:11:06

0:04:06

0:04:06

0:10:47

0:10:47

0:10:15

0:10:15

0:03:09

0:03:09

0:02:59

0:02:59

0:12:07

0:12:07

0:20:03

0:20:03

0:02:34

0:02:34

0:11:58

0:11:58

0:07:47

0:07:47

0:17:26

0:17:26

0:12:33

0:12:33

0:16:08

0:16:08

0:05:38

0:05:38

0:13:15

0:13:15

0:05:47

0:05:47

0:22:03

0:22:03

0:14:17

0:14:17

0:01:45

0:01:45

0:11:40

0:11:40

0:09:59

0:09:59