filmov

tv

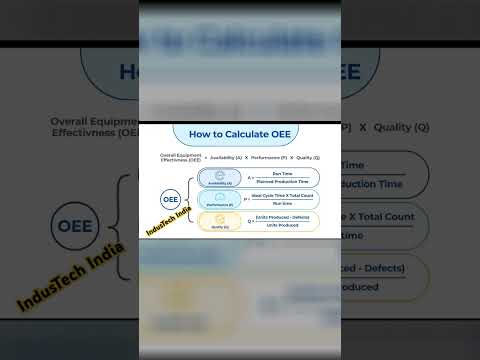

How to Calculate OEE at the Plant Level?

Показать описание

In this video, Walker Reynolds answers a question we get all the time: What method do I use to Calculate or Summarize OEE at the Area Level and at the Plant Level?

Do I average the Line OEE Numbers together?

Or do I sum up production time, production units, and total planned production time and then re-calculate OEE using those numbers?

The answer is the second one.

Want to learn more about Implementing OEE in your Manufacturing Plant?

Thanks for watching!

Subscribe!

Want to learn more?

Join our community Discord Server

Take the FREE IIoT Mini-Course

#IIoT #Industry40 #DigitalTransformation

Do I average the Line OEE Numbers together?

Or do I sum up production time, production units, and total planned production time and then re-calculate OEE using those numbers?

The answer is the second one.

Want to learn more about Implementing OEE in your Manufacturing Plant?

Thanks for watching!

Subscribe!

Want to learn more?

Join our community Discord Server

Take the FREE IIoT Mini-Course

#IIoT #Industry40 #DigitalTransformation

OEE Calculation - Overall Equipment Effectiveness

OEE (Overall Equipment Effectiveness) – What is it and how to calculate it!

OEE Calculation Example

How to Calculate OEE and why you need to

OEE Calculation In Microsoft Excel: Illustration With Practical Example

What is OEE | How to Calculate OEE?

How to Calculate OEE at the Plant Level?

What is OEE and How to Calculate It? | #LeanSixSigma #OpEx #SixSigma #ASQGreenBelt #CSSGB

What is OEE and How To Calculate | Mastering Maintenance Overall Equipment Effectiveness

How to calculate OEE

How to Calculate OEE in Excel

OEE | #oee #manufacturing #production

How to calculate OEE and what is Overall Equipment Effectiveness & Loss Analysis introduction

|| How to calculate OEE || OEE Calculation || #shorts #ytshorts #learning @industechindia

OEE SHEET | OEE calculation example |How to calculate OEE |

What is OEE Overall Equipment Effectiveness ? Overall Equipment Effectiveness (OEE) calculation

OEE Sample calculation

How to Calculate OEE.wmv

OEE find out every Industry production ratio (overall equipment effectiveness)#entrancetests ❤ 😍 💖...

Calculating OEE: Availability, Performance + Quality

How to Calculate OEE using FREE OEE Calculator

Calculate OEE with HAL APS

HOW TO CALCULATE OEE

What is Overall equipment effectiveness and How to calculate OEE?

Комментарии

0:03:31

0:03:31

0:23:53

0:23:53

0:02:51

0:02:51

0:14:45

0:14:45

0:09:13

0:09:13

0:06:07

0:06:07

0:05:50

0:05:50

0:00:44

0:00:44

0:02:44

0:02:44

0:04:41

0:04:41

0:18:34

0:18:34

0:00:16

0:00:16

0:02:35

0:02:35

0:00:05

0:00:05

0:11:44

0:11:44

0:10:00

0:10:00

0:06:14

0:06:14

0:01:44

0:01:44

0:00:16

0:00:16

0:01:24

0:01:24

0:14:50

0:14:50

0:00:57

0:00:57

0:06:33

0:06:33

0:01:07

0:01:07