filmov

tv

How To Fabricate A Chassis - Building a Model A Hot Rod with Eastwood

Показать описание

Matt tackles the task of fabricating his own chassis for the Model A hot rod he's putting together.

Read an in depth breakdown of the project here:

Eastwood has everything you need to do the job right when you're restoring a car, truck or motorcycle - from welders to paint and everything in between.

Are YOU an Eastwood Guy?

Read an in depth breakdown of the project here:

Eastwood has everything you need to do the job right when you're restoring a car, truck or motorcycle - from welders to paint and everything in between.

Are YOU an Eastwood Guy?

How To Fabricate A Chassis - Building a Model A Hot Rod with Eastwood

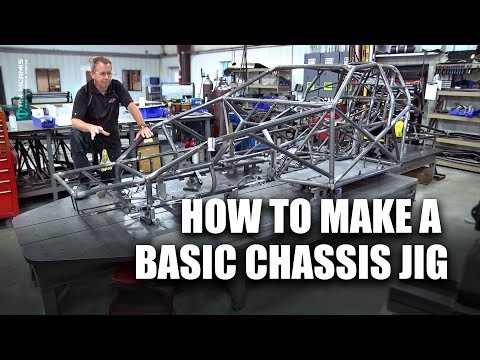

How To Make A Basic Chassis Jig

We Might Delete this Video (our chassis engineering secrets)

How I Built a Handmade Chassis for my Turbo 1968 Chevy C10 Build

Supercar Chassis

How much does it cost to build a tube car chassis?

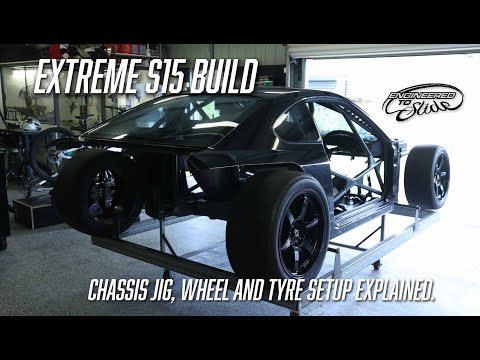

Extreme S15 Build : Chassis JIG, Tyre and Wheel setup explained.

Built from Scratch 1970 Dodge Charger Chassis 03.2

M2C RACING chassis brace for the K4s

Let's Build a Chassis Jig

From Sheet Metal to Suspension! - Road Race Chassis for the Hot Rod Rebuild

Custom Roadster Shop Chassis: How it works...

OEM metal sheet fabrication for truck chassis

We convinced Tim to make a Fox Body chassis so you can build one too.

Lining Up the Engine with the Chassis

The Ultimate Ford + Chevy Chassis [FULLY LOADED]

3 rolling chassis at MetalWorks Classic Auto & Speed Shop including Art Morrison & Roadster ...

How To Build DIY Chassis Table - Welding It All Together Using the Eastwood MIG 250!

The correct way to make welded splice joints in chassis members

C30 Custom Chassis Build for SEMA 2018

Roadster Shop SPEC Chassis Kits Fabrication and Manufacturing - Shop Talk

Door Slammer Build: 01 - Chassis Construction

Learning Chassis Fabrication from a PRO | Mullis Race Cars

I Build New Rock Bouncer Chassis for myself

Комментарии

0:12:01

0:12:01

0:06:50

0:06:50

0:23:50

0:23:50

0:14:29

0:14:29

0:00:35

0:00:35

0:03:25

0:03:25

0:08:54

0:08:54

0:19:25

0:19:25

0:00:30

0:00:30

0:21:39

0:21:39

0:16:44

0:16:44

0:03:16

0:03:16

0:01:08

0:01:08

0:03:54

0:03:54

0:10:33

0:10:33

0:08:57

0:08:57

0:01:59

0:01:59

0:07:56

0:07:56

0:19:47

0:19:47

0:01:00

0:01:00

0:02:47

0:02:47

0:05:19

0:05:19

0:11:09

0:11:09

0:06:53

0:06:53