filmov

tv

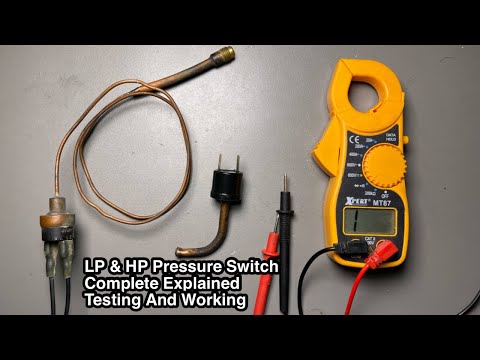

HP LP Switch Explained: High & Low pressure switches in HVAC Systems |MK Technical Solutions ' .....

Показать описание

HP and LP Switches Explained: Full Guide to High and Low-Pressure Switches

HP (High Pressure) and LP (Low Pressure) switches are critical components used in various HVAC and refrigeration systems to maintain pressure balance and prevent potential system damage. In this video, we’ll break down how these switches work, their differences, troubleshooting tips, and why they are essential for efficient system operations.

Introduction to HP and LP Switches

HP and LP switches are designed to monitor and control pressure levels in HVAC systems. They act as safety devices, shutting down the system when pressures become too high or too low, which can lead to equipment failure or inefficiencies.

HP Switch (High Pressure Switch):

The HP switch is responsible for monitoring high-pressure levels in a system. When the pressure exceeds the safe limit, the switch cuts off the system to prevent damage. This is crucial in systems like refrigeration and air conditioning, where overpressure can lead to system failure.

LP Switch (Low Pressure Switch):

On the other hand, the LP switch is designed to detect low-pressure conditions. When the pressure drops below a certain threshold, the LP switch shuts off the system to protect against under-pressurization, which can lead to inadequate cooling or damage to compressors.

How Do HP and LP Switches Work in HVAC Systems?

Both HP and LP switches are pressure-sensitive devices connected to the system via sensors. They work in tandem to ensure optimal system performance.

1. HP Switch Working:

The HP switch monitors the refrigerant pressure in HVAC systems. If the pressure rises above a set point, the switch sends a signal to shut off the compressor to prevent damage caused by excessive pressure.

Common causes of high pressure include dirty condenser coils, overcharging refrigerant, or blockages in the system.

2. LP Switch Working:

The LP switch, on the other hand, detects when the system’s pressure drops too low. When this happens, the switch shuts off the compressor to avoid underperformance or damage.

Low pressure often occurs due to refrigerant leaks, clogged filters, or improper refrigerant charge.

Key Differences Between HP and LP Switches:

While HP and LP switches serve the same fundamental purpose of pressure regulation, they focus on opposite pressure extremes.

Functionality:

The HP switch responds to overpressure conditions.

The LP switch responds to under-pressure conditions.

Safety Mechanism:

HP switches prevent compressor damage caused by excessive pressure.

LP switches prevent system failure caused by a loss of refrigerant or low pressure.

Placement:

HP switches are typically placed on the high-pressure side of the system.

LP switches are placed on the low-pressure side, near the evaporator.

Common Problems and Troubleshooting HP and LP Switches

HVAC and refrigeration systems rely heavily on HP and LP switches for smooth operation. However, when these switches malfunction, they can cause system shutdowns or inefficiencies.

Troubleshooting HP Switch Problems:

If your system is frequently shutting down due to high pressure, check the following:

1. Dirty Coils: Dirty or blocked condenser coils can cause pressure buildup. Clean them regularly to prevent issues.

2. Overcharged Refrigerant: Excess refrigerant can cause high pressure in the system. Proper refrigerant charging is crucial for maintaining balance.

3. Clogged Refrigerant Lines: Blockages in the refrigerant lines can also cause excessive pressure buildup.

Troubleshooting LP Switch Problems:

Low-pressure switch issues usually stem from:

1. Refrigerant Leaks: If the refrigerant level is too low, the LP switch will shut down the system. Check for leaks and recharge the refrigerant.

2. Clogged Filters: Airflow obstructions can cause low pressure. Clean or replace filters regularly.

3. Faulty Sensors: Sometimes, the LP switch sensor might fail, leading to incorrect pressure readings. In such cases, the switch may need to be replaced.

Importance of Proper Maintenance

Regular maintenance of HP and LP switches is essential to prevent malfunctions and extend the life of HVAC systems. Here are some maintenance tips:

Regular Cleaning: Keep condenser coils, filters, and refrigerant lines clean to prevent pressure-related issues.

For more videos on HVAC systems, technical solutions, and troubleshooting tips, make sure to subscribe to MK Technical Solutions and turn on notifications for the latest updates.

Call to Action: If you found this video helpful, give it a thumbs up, share it with fellow technicians, and leave a comment below with any questions. Don’t forget to subscribe to MK Technical Solutions for more detailed guides on HVAC systems and components!

---

Hashtags: #HPswitch #LPswitch #HVACtroubleshooting #MKTechnicalSolutions #HVACpressureSwitches #TechnicalSolutions

HP (High Pressure) and LP (Low Pressure) switches are critical components used in various HVAC and refrigeration systems to maintain pressure balance and prevent potential system damage. In this video, we’ll break down how these switches work, their differences, troubleshooting tips, and why they are essential for efficient system operations.

Introduction to HP and LP Switches

HP and LP switches are designed to monitor and control pressure levels in HVAC systems. They act as safety devices, shutting down the system when pressures become too high or too low, which can lead to equipment failure or inefficiencies.

HP Switch (High Pressure Switch):

The HP switch is responsible for monitoring high-pressure levels in a system. When the pressure exceeds the safe limit, the switch cuts off the system to prevent damage. This is crucial in systems like refrigeration and air conditioning, where overpressure can lead to system failure.

LP Switch (Low Pressure Switch):

On the other hand, the LP switch is designed to detect low-pressure conditions. When the pressure drops below a certain threshold, the LP switch shuts off the system to protect against under-pressurization, which can lead to inadequate cooling or damage to compressors.

How Do HP and LP Switches Work in HVAC Systems?

Both HP and LP switches are pressure-sensitive devices connected to the system via sensors. They work in tandem to ensure optimal system performance.

1. HP Switch Working:

The HP switch monitors the refrigerant pressure in HVAC systems. If the pressure rises above a set point, the switch sends a signal to shut off the compressor to prevent damage caused by excessive pressure.

Common causes of high pressure include dirty condenser coils, overcharging refrigerant, or blockages in the system.

2. LP Switch Working:

The LP switch, on the other hand, detects when the system’s pressure drops too low. When this happens, the switch shuts off the compressor to avoid underperformance or damage.

Low pressure often occurs due to refrigerant leaks, clogged filters, or improper refrigerant charge.

Key Differences Between HP and LP Switches:

While HP and LP switches serve the same fundamental purpose of pressure regulation, they focus on opposite pressure extremes.

Functionality:

The HP switch responds to overpressure conditions.

The LP switch responds to under-pressure conditions.

Safety Mechanism:

HP switches prevent compressor damage caused by excessive pressure.

LP switches prevent system failure caused by a loss of refrigerant or low pressure.

Placement:

HP switches are typically placed on the high-pressure side of the system.

LP switches are placed on the low-pressure side, near the evaporator.

Common Problems and Troubleshooting HP and LP Switches

HVAC and refrigeration systems rely heavily on HP and LP switches for smooth operation. However, when these switches malfunction, they can cause system shutdowns or inefficiencies.

Troubleshooting HP Switch Problems:

If your system is frequently shutting down due to high pressure, check the following:

1. Dirty Coils: Dirty or blocked condenser coils can cause pressure buildup. Clean them regularly to prevent issues.

2. Overcharged Refrigerant: Excess refrigerant can cause high pressure in the system. Proper refrigerant charging is crucial for maintaining balance.

3. Clogged Refrigerant Lines: Blockages in the refrigerant lines can also cause excessive pressure buildup.

Troubleshooting LP Switch Problems:

Low-pressure switch issues usually stem from:

1. Refrigerant Leaks: If the refrigerant level is too low, the LP switch will shut down the system. Check for leaks and recharge the refrigerant.

2. Clogged Filters: Airflow obstructions can cause low pressure. Clean or replace filters regularly.

3. Faulty Sensors: Sometimes, the LP switch sensor might fail, leading to incorrect pressure readings. In such cases, the switch may need to be replaced.

Importance of Proper Maintenance

Regular maintenance of HP and LP switches is essential to prevent malfunctions and extend the life of HVAC systems. Here are some maintenance tips:

Regular Cleaning: Keep condenser coils, filters, and refrigerant lines clean to prevent pressure-related issues.

For more videos on HVAC systems, technical solutions, and troubleshooting tips, make sure to subscribe to MK Technical Solutions and turn on notifications for the latest updates.

Call to Action: If you found this video helpful, give it a thumbs up, share it with fellow technicians, and leave a comment below with any questions. Don’t forget to subscribe to MK Technical Solutions for more detailed guides on HVAC systems and components!

---

Hashtags: #HPswitch #LPswitch #HVACtroubleshooting #MKTechnicalSolutions #HVACpressureSwitches #TechnicalSolutions

Комментарии

0:00:16

0:00:16

0:07:37

0:07:37

0:04:00

0:04:00

0:05:56

0:05:56

0:00:29

0:00:29

0:19:13

0:19:13

0:09:13

0:09:13

0:05:26

0:05:26

0:01:01

0:01:01

0:04:07

0:04:07

0:09:14

0:09:14

0:05:45

0:05:45

0:14:38

0:14:38

0:06:22

0:06:22

0:01:28

0:01:28

0:06:47

0:06:47

0:03:53

0:03:53

0:04:38

0:04:38

0:03:54

0:03:54

0:12:11

0:12:11

0:07:01

0:07:01

0:09:58

0:09:58

0:09:10

0:09:10

0:05:57

0:05:57