filmov

tv

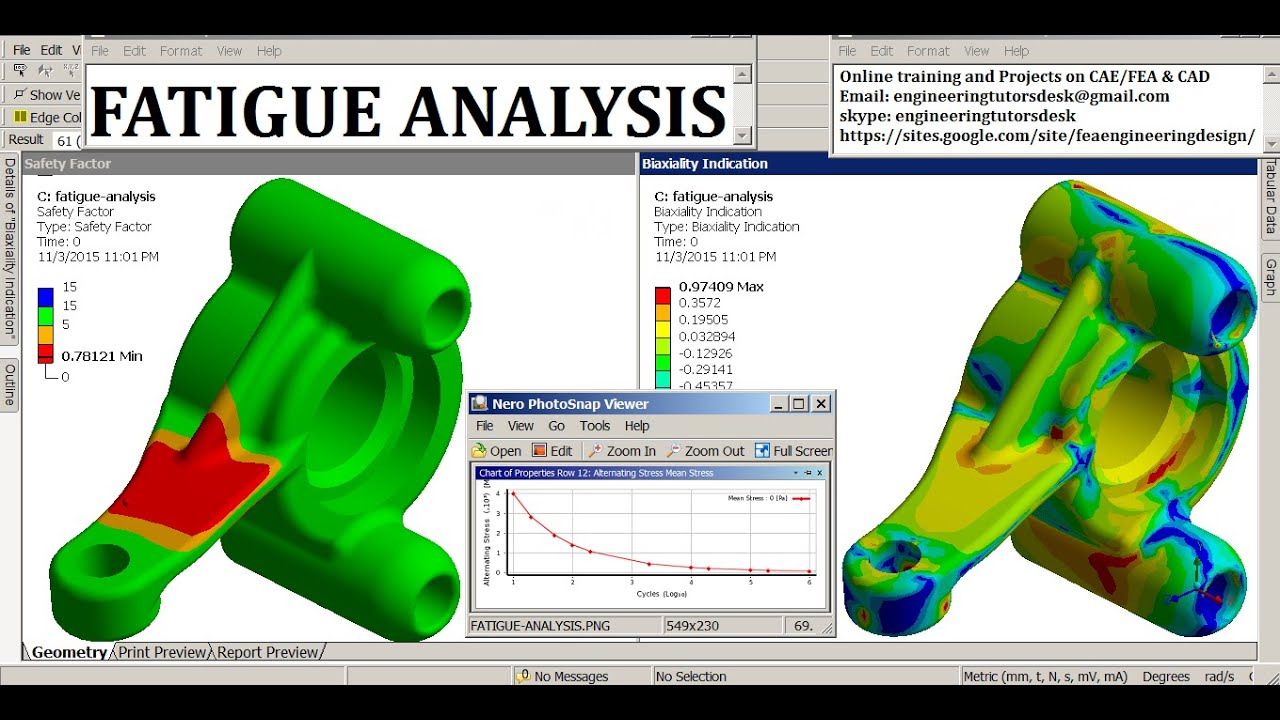

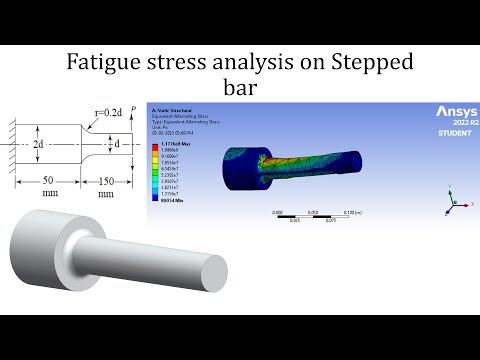

Fatigue Analysis in ANSYS | Fatigue Failure | HCF High Cycle & LCF Low Cycle Fatigue Life | GRS |

Показать описание

00:00 - Introduction to the problem

02:00 - Types of Fatigue Analysis (Stress life, Strain life & Crack life)

03:00 - Categories of Fatigue (High & Low cycle)

03:38 - Table of Stress vs Life

06:00 - Fatigue life evaluation

11:10 - Creating the Analysis file

12:10 - Unit setting, Material definition & Geometry Import

16:47 - Defining the Mesh

18:16 - Applying loads & Boundary conditions

19:58 - Static Analysis

20:45 - Fatigue Theories

24:00 - Fatigue life evaluation results

24:59 - Post processing of Fatigue results

For Online Training & Projects, WhatsApp: +91-9481635839 | INDIA

#DesignLifeEvaluation

#FatigueCategories

#ANSYSWorkbench

ANSYS Videos Playlist

ANSYS CFD Playlist

Hypermesh Videos

CAD Modelling Techniques

Creo Simulate Videos

This video will take you through how to evaluate the fatigue failure and the fatigue analysis methods, high cycle fatigue, low cycle fatigue, stress life fatigue analysis, strain life fatigue analysis, fracture mechanics, SN curve for structural steel, Alternating stress vs Number of cycles, What is fatigue life, fatigue damage, Fatigue Safety Factor, Bi Axiality, Sensitivity Curve, What are the Mean Stress correction Theory, Goodman equation in Fatigue analysis, Von Mises Stress approach for fatigue analysis, Fatigue Strength Correction Factor

How to decide whether fatigue analysis is required

01. Component/structure type: Consider if the component experiences cyclic loading or repeated stress.

02. Loading conditions: Assess if the component is subjected to fluctuating or cyclic loads.

03. Material properties: Evaluate the susceptibility of the material to fatigue failure.

04. Operational lifespan: Determine if the component is expected to endure a large number of load cycles.

05. Safety criticality: Consider if the failure of the component could have severe consequences.

06. Regulatory requirements: Check if specific industry regulations or standards mandate fatigue analysis.

07. Past failures/known issues: Consider any previous fatigue failures or known fatigue-related problems.

Where/How to get the fatigue curve or SN curve of specific material

01. Experimental Testing: Conducting fatigue tests on specific materials or components provides real-world data to generate fatigue curves. These tests involve subjecting the material or component to cyclic loading under controlled conditions while measuring the number of cycles to failure.

02. Material Standards and Specifications: Many engineering materials have established standards or specifications that include fatigue data. These documents often provide S-N curves for different materials, including metals, composites, and polymers. Standards organizations such as ASTM, ISO, and SAE publish these standards.

03. Materials Databases: Several databases compile fatigue data from various sources, including experimental studies and research papers. These databases may require a subscription or membership for access. Examples include the NIST Materials Data Repository, the MatWeb database, and the Fatigue Data Handbook.

04. Published Research: Research papers, technical journals, and conference proceedings often present fatigue test results and S-N curves for specific materials or components. These publications can be found through academic databases, online libraries, or by directly contacting researchers in the field.

05. Industry Guidelines and Handbooks: Certain industries have guidelines or handbooks that provide fatigue curves specific to their applications. For example, the American Institute of Steel Construction (AISC) provides fatigue design guidance for steel structures, including S-N curves for various steel grades.

02:00 - Types of Fatigue Analysis (Stress life, Strain life & Crack life)

03:00 - Categories of Fatigue (High & Low cycle)

03:38 - Table of Stress vs Life

06:00 - Fatigue life evaluation

11:10 - Creating the Analysis file

12:10 - Unit setting, Material definition & Geometry Import

16:47 - Defining the Mesh

18:16 - Applying loads & Boundary conditions

19:58 - Static Analysis

20:45 - Fatigue Theories

24:00 - Fatigue life evaluation results

24:59 - Post processing of Fatigue results

For Online Training & Projects, WhatsApp: +91-9481635839 | INDIA

#DesignLifeEvaluation

#FatigueCategories

#ANSYSWorkbench

ANSYS Videos Playlist

ANSYS CFD Playlist

Hypermesh Videos

CAD Modelling Techniques

Creo Simulate Videos

This video will take you through how to evaluate the fatigue failure and the fatigue analysis methods, high cycle fatigue, low cycle fatigue, stress life fatigue analysis, strain life fatigue analysis, fracture mechanics, SN curve for structural steel, Alternating stress vs Number of cycles, What is fatigue life, fatigue damage, Fatigue Safety Factor, Bi Axiality, Sensitivity Curve, What are the Mean Stress correction Theory, Goodman equation in Fatigue analysis, Von Mises Stress approach for fatigue analysis, Fatigue Strength Correction Factor

How to decide whether fatigue analysis is required

01. Component/structure type: Consider if the component experiences cyclic loading or repeated stress.

02. Loading conditions: Assess if the component is subjected to fluctuating or cyclic loads.

03. Material properties: Evaluate the susceptibility of the material to fatigue failure.

04. Operational lifespan: Determine if the component is expected to endure a large number of load cycles.

05. Safety criticality: Consider if the failure of the component could have severe consequences.

06. Regulatory requirements: Check if specific industry regulations or standards mandate fatigue analysis.

07. Past failures/known issues: Consider any previous fatigue failures or known fatigue-related problems.

Where/How to get the fatigue curve or SN curve of specific material

01. Experimental Testing: Conducting fatigue tests on specific materials or components provides real-world data to generate fatigue curves. These tests involve subjecting the material or component to cyclic loading under controlled conditions while measuring the number of cycles to failure.

02. Material Standards and Specifications: Many engineering materials have established standards or specifications that include fatigue data. These documents often provide S-N curves for different materials, including metals, composites, and polymers. Standards organizations such as ASTM, ISO, and SAE publish these standards.

03. Materials Databases: Several databases compile fatigue data from various sources, including experimental studies and research papers. These databases may require a subscription or membership for access. Examples include the NIST Materials Data Repository, the MatWeb database, and the Fatigue Data Handbook.

04. Published Research: Research papers, technical journals, and conference proceedings often present fatigue test results and S-N curves for specific materials or components. These publications can be found through academic databases, online libraries, or by directly contacting researchers in the field.

05. Industry Guidelines and Handbooks: Certain industries have guidelines or handbooks that provide fatigue curves specific to their applications. For example, the American Institute of Steel Construction (AISC) provides fatigue design guidance for steel structures, including S-N curves for various steel grades.

Комментарии

0:05:11

0:05:11

0:38:09

0:38:09

0:06:37

0:06:37

0:07:48

0:07:48

0:29:35

0:29:35

0:12:01

0:12:01

0:18:52

0:18:52

0:53:31

0:53:31

0:29:01

0:29:01

0:37:48

0:37:48

0:17:09

0:17:09

0:33:36

0:33:36

0:08:23

0:08:23

0:14:20

0:14:20

0:26:40

0:26:40

0:01:52

0:01:52

0:11:40

0:11:40

0:01:22

0:01:22

0:16:59

0:16:59

2:00:52

2:00:52

0:01:02

0:01:02

2:03:20

2:03:20

0:07:45

0:07:45

0:08:36

0:08:36