filmov

tv

How to Wire a Thermocouple to a PLC

Показать описание

▶ You can read the full post here

⌚Timestamps:

00:00 - Intro

00:36 - Junctions and voltages

01:08 - Thermocouple types

01:57 - Connect a thermocouple to a PLC

03:06 - 1) Connected directly to PLC

03:59 - 2) Located at a distance from the PLC

=============================

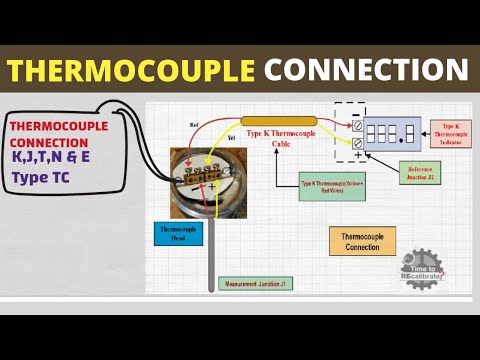

In this video, we’re going to show you how to wire a thermocouple to a PLC analog input module. We’re also going to discuss thermocouple Cold Junction Compensation and challenges when working with Extension wires.

A thermocouple is made up of two dissimilar metal wires. These two dissimilar metals are joined together at one end and open at the other end. The joined end is called the Measurement Junction.

Heat applied to the Measurement Junction will produce a voltage across the open end. As the applied heat increases, so does the open-ended voltage.

Thermocouple manufacturers have purposely chosen metal wire pairs that produce 0 volts at 0 °C.

Certain wire pairs have become popular as industry standards and assigned letters to indicate their Type. For example, a Type K thermocouple is made from alloys Chromel and Alumel.

Thermocouple Tables have been produced listing the resulting voltage at specific temperature values.

Well, if we want to make a temperature reading it seems easy enough!

All we need to do is measure the open-end voltage. Unfortunately, it isn’t that easy.

- First of all, the voltages produced are very small and the actual change in voltage per degree Celsius is minuscule.

- Secondly, as soon as you connect a measuring device to the open end, you create more junctions that create unwanted voltages!

Most PLC vendors offer Thermocouple modules. These specially designed analog modules provide what’s referred to as Cold Junction Compensation that eliminates the effect of any new junctions created.

The Siemens 6ES7 531-7PF00-0AB0 is an Analog Input module capable of connecting eight thermocouples.

This particular module offers several options for providing cold junction compensation. Why are there different options?

Well, for one reason, the cold junction can be at different locations depending upon the application and the location of the thermocouple.

Scenario #1: Let’s look at an application where the thermocouple is connected directly to one of the module inputs.

In this example, we’re wiring a Type K thermocouple to terminals 3 and 4 of the module. The positive yellow-insulated wire is connected to Terminal 3. The negative red-insulated wire is connected to Terminal 4.

As a rule of thumb, thermocouple wires with red insulation are negative.

In this wiring scenario, the Cold Junction is right at the terminals of the analog module. The module has an internal sensor that can compensate for the cold junction.

The Thermocouple Type and the source of cold junction compensation are configured in the Siemens STEP 7 software program.

Scenario #2: What if the thermocouple was located at a distance from the PLC?

In this scenario, you can use the thermocouple extension wire because using standard copper wire creates new junctions and unwanted voltages.

A thermocouple extension wire is made of the same material as the thermocouple thereby eliminating any possible new junctions. Using thermocouple termination blocks will ensure that new junctions are not created.

With thermocouple extension wires, the Cold Junction is at the terminals of the analog module and therefore the module can be configured as in our first scenario.

With thermocouple extension wires, the Cold Junction is at the terminals of the analog module and therefore the module can be configured as in our first scenario.

=============================

=============================

Missed our most recent videos? Watch them here:

=============================

=============================

To stay up to date with our last videos, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #Thermocouple #Industry

Комментарии

0:04:02

0:04:02

0:06:30

0:06:30

0:04:16

0:04:16

0:01:20

0:01:20

0:00:25

0:00:25

0:06:04

0:06:04

0:01:54

0:01:54

0:09:05

0:09:05

0:06:35

0:06:35

0:06:01

0:06:01

0:01:13

0:01:13

0:02:01

0:02:01

0:01:41

0:01:41

0:00:20

0:00:20

0:10:43

0:10:43

0:00:20

0:00:20

0:05:18

0:05:18

0:05:29

0:05:29

0:01:29

0:01:29

0:14:36

0:14:36

0:03:51

0:03:51

0:07:51

0:07:51

0:08:50

0:08:50

0:03:03

0:03:03