filmov

tv

Learn Oil Analysis - Wear Metal Elements (ICP) & PQ

Показать описание

Unveiling Wear Metals and Additives in Lubricating Oils: ICP Analysis and PQ Index Insights.

Embark on an enlightening journey into the world of wear metals, additive elements, and their detection in lubricating oils with our latest video. This detailed guide is an invaluable resource for maintenance engineers, lubrication specialists, and anyone interested in the advanced techniques used in oil analysis for machinery maintenance.

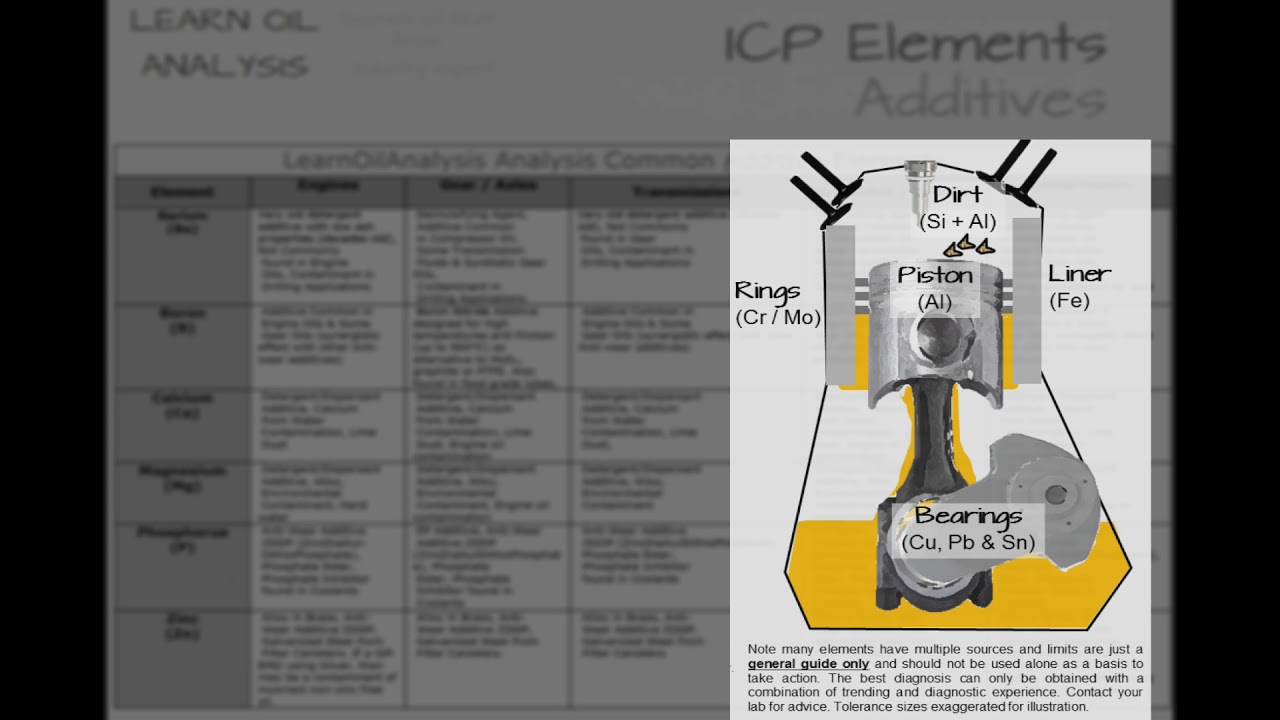

The video begins with an overview of wear metals and additive elements in lubricating oils, discussing their origins and significance in machinery health. We illustrate how different elements can indicate specific types of wear or contamination. For instance, iron might point to general wear, whereas chromium could suggest bearing wear, and silicon often indicates dirt ingress.

Next, we delve into the principles of Inductively Coupled Plasma (ICP) spectroscopy, a pivotal method in oil analysis. The presenter explains how ICP works to detect and measure the quantities of various metal elements in oil, offering insights into the internal condition of machinery. The discussion includes the benefits and limitations of ICP, providing a well-rounded understanding of its application in industrial settings.

We then explore the PQ (Particle Quantifier) Index, a technique used to quantify ferrous wear particles in lubricating oils. The PQ Index is crucial for detecting larger particles that ICP might miss, thereby offering a more comprehensive view of wear trends. We discuss how the combination of ICP and PQ Index data can provide a more complete picture of the wear status in machinery.

The video also covers the typical sources of various elements detected in oil analysis. For example, copper may originate from bushings or bearings, zinc from anti-wear additives, and molybdenum from certain types of grease or additives. Understanding these element sources aids in pinpointing potential issues within different machine components.

Throughout the presentation, we maintain an engaging and informative style, ensuring complex concepts are made accessible. The video is filled with real-world examples, charts, and imagery to enhance understanding, making it ideal for both beginners and seasoned professionals in the field of machinery maintenance and reliability.

Embark on an enlightening journey into the world of wear metals, additive elements, and their detection in lubricating oils with our latest video. This detailed guide is an invaluable resource for maintenance engineers, lubrication specialists, and anyone interested in the advanced techniques used in oil analysis for machinery maintenance.

The video begins with an overview of wear metals and additive elements in lubricating oils, discussing their origins and significance in machinery health. We illustrate how different elements can indicate specific types of wear or contamination. For instance, iron might point to general wear, whereas chromium could suggest bearing wear, and silicon often indicates dirt ingress.

Next, we delve into the principles of Inductively Coupled Plasma (ICP) spectroscopy, a pivotal method in oil analysis. The presenter explains how ICP works to detect and measure the quantities of various metal elements in oil, offering insights into the internal condition of machinery. The discussion includes the benefits and limitations of ICP, providing a well-rounded understanding of its application in industrial settings.

We then explore the PQ (Particle Quantifier) Index, a technique used to quantify ferrous wear particles in lubricating oils. The PQ Index is crucial for detecting larger particles that ICP might miss, thereby offering a more comprehensive view of wear trends. We discuss how the combination of ICP and PQ Index data can provide a more complete picture of the wear status in machinery.

The video also covers the typical sources of various elements detected in oil analysis. For example, copper may originate from bushings or bearings, zinc from anti-wear additives, and molybdenum from certain types of grease or additives. Understanding these element sources aids in pinpointing potential issues within different machine components.

Throughout the presentation, we maintain an engaging and informative style, ensuring complex concepts are made accessible. The video is filled with real-world examples, charts, and imagery to enhance understanding, making it ideal for both beginners and seasoned professionals in the field of machinery maintenance and reliability.

Комментарии

0:10:56

0:10:56

0:40:49

0:40:49

0:04:11

0:04:11

0:04:02

0:04:02

0:04:43

0:04:43

0:04:38

0:04:38

0:03:45

0:03:45

0:07:16

0:07:16

0:07:25

0:07:25

0:04:31

0:04:31

0:01:38

0:01:38

1:11:32

1:11:32

0:02:28

0:02:28

0:06:21

0:06:21

0:58:40

0:58:40

0:03:10

0:03:10

0:06:21

0:06:21

0:02:03

0:02:03

0:34:42

0:34:42

0:03:31

0:03:31

0:02:31

0:02:31

0:05:34

0:05:34

0:02:56

0:02:56

0:05:31

0:05:31