filmov

tv

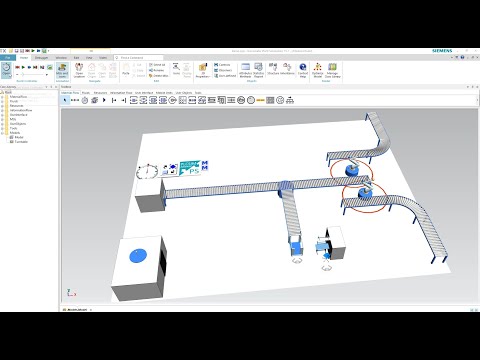

Virtual Commissioning Case Study: Motor Sizing & Control Design Using MapleSim

Показать описание

Designing new products requires a precise balance between costs and performance. If you miss the mark, you might be overspending or risking malfunction. What if you had a tool that would give you the precision you need to find that balance?

A company designing injection molding machines needed to validate a new, low-cost design to stay competitive. They had to ensure that it would function properly and withstand years of service.

To get their product to market faster, and to save on physical testing costs, they turned to MapleSim, the system-level modeling software from Maplesoft.

See how MapleSim was used to:

• Create a high-fidelity, dynamic model of the new machine

• Provide accurate torque requirements for confident motor sizing

• Help develop stable, robust controllers by testing code against the model using virtual commissioning

• Safely test a variety of operation scenarios in software, without risking damage to the physical machine

Learn more of how to benefit from digital twins for virtual commissioning:

For more information, visit us at:

A company designing injection molding machines needed to validate a new, low-cost design to stay competitive. They had to ensure that it would function properly and withstand years of service.

To get their product to market faster, and to save on physical testing costs, they turned to MapleSim, the system-level modeling software from Maplesoft.

See how MapleSim was used to:

• Create a high-fidelity, dynamic model of the new machine

• Provide accurate torque requirements for confident motor sizing

• Help develop stable, robust controllers by testing code against the model using virtual commissioning

• Safely test a variety of operation scenarios in software, without risking damage to the physical machine

Learn more of how to benefit from digital twins for virtual commissioning:

For more information, visit us at:

0:15:21

0:15:21

0:01:13

0:01:13

0:24:20

0:24:20

0:22:53

0:22:53

0:02:29

0:02:29

0:00:27

0:00:27

0:27:48

0:27:48

0:07:43

0:07:43

0:03:23

0:03:23

0:08:07

0:08:07

0:02:31

0:02:31

0:43:03

0:43:03

0:04:29

0:04:29

0:12:25

0:12:25

0:03:04

0:03:04

0:01:49

0:01:49

0:05:16

0:05:16

0:12:25

0:12:25

0:00:28

0:00:28

0:02:54

0:02:54

0:20:12

0:20:12

0:03:29

0:03:29

0:22:21

0:22:21

0:01:55

0:01:55